Powdered activated carbon dosing system with pre-dispersion and weighing mechanism

A technology of powdered activated carbon and weighing mechanism, which is applied in the direction of mixers, mixer accessories, chemical instruments and methods, etc., can solve problems such as uneven powdered activated carbon powder, low utilization rate of powdered activated carbon, and influence on water treatment effects, etc., to improve The accuracy of feeding and metering, the firmness of the device, and the effect of preventing dust from powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the accompanying drawings.

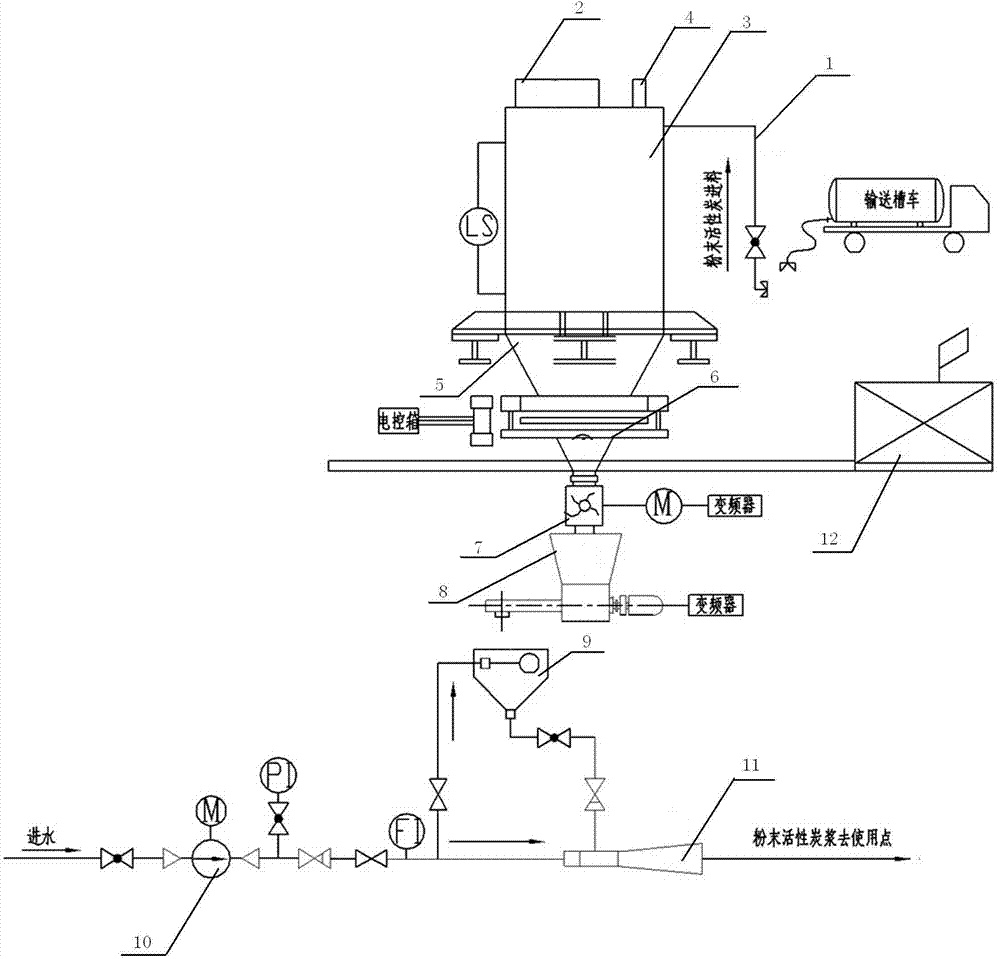

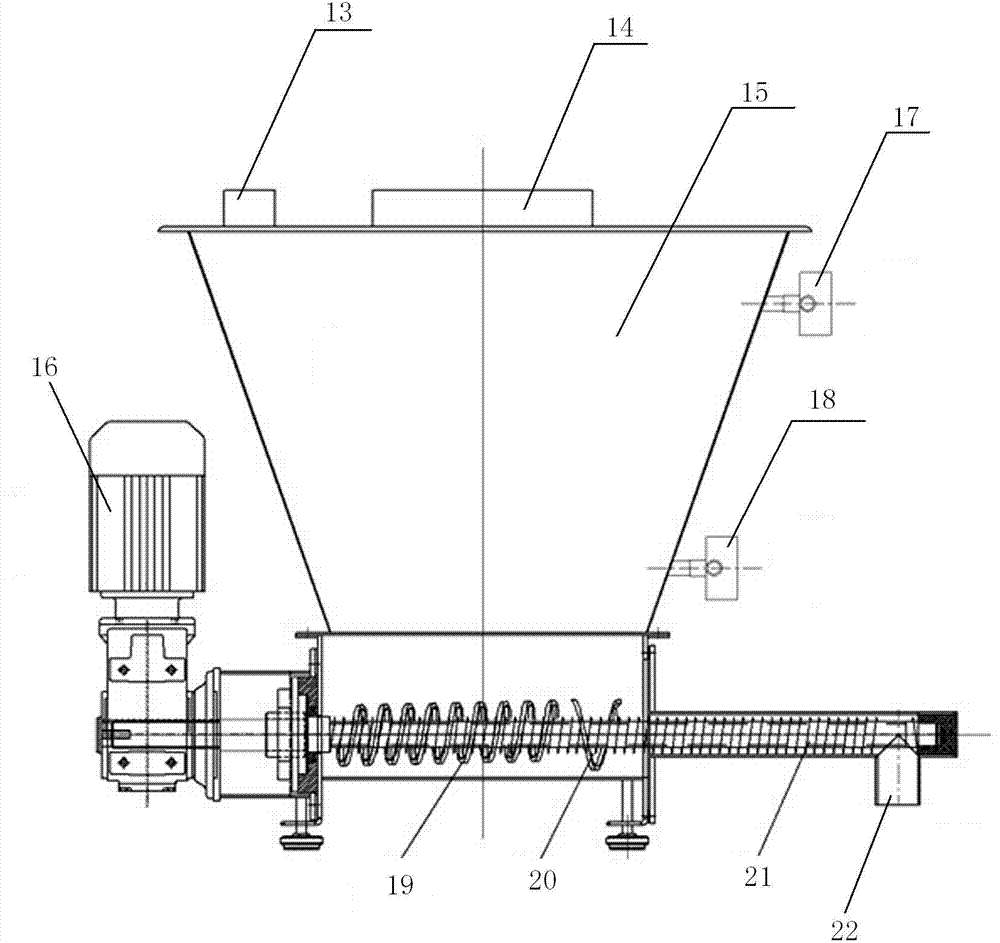

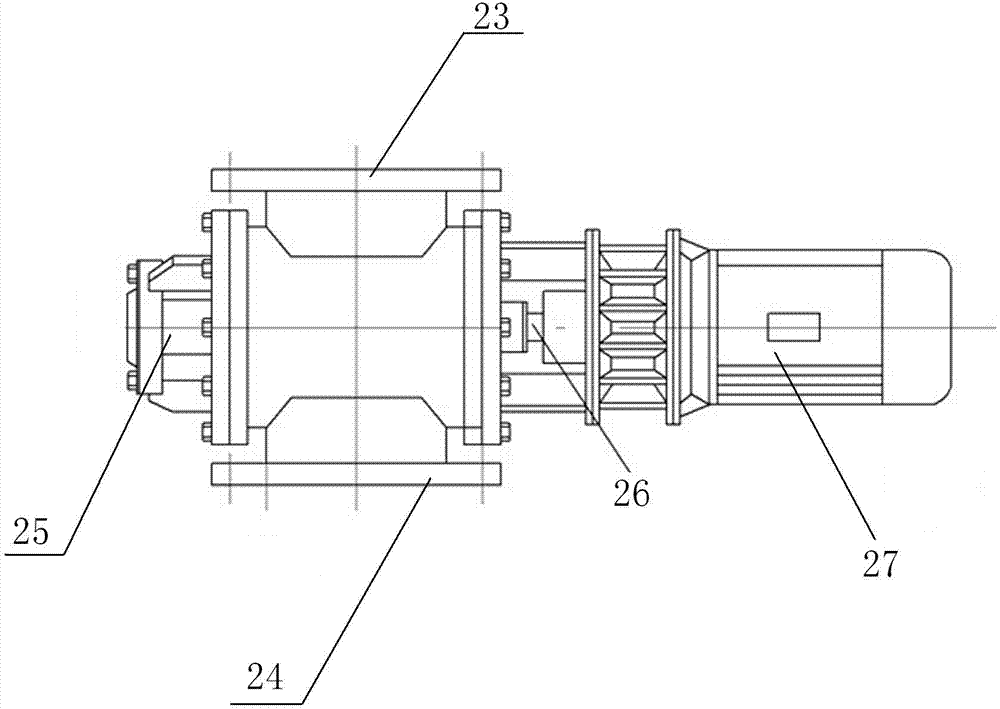

[0020] The present invention is a powder activated carbon dosing system with a pre-dispersion and weighing mechanism, such as figure 1 As shown in , it includes a powdered activated carbon silo 3, a cone bucket 5 is installed at the bottom of the powdered activated carbon silo 3, and an anti-cavitation vibration device 6 is installed at the bottom of the cone bucket 5, which is different from the prior art in that: the powdered activated carbon silo 3 A powdered activated carbon feed pipeline 1 is provided at the top of the powdered activated carbon silo 3, and a bag filter 2 and a breathing valve 4 are installed on the top of the powdered activated carbon silo 3. The lower part of the cone bucket 5 is connected to the upper part of the anti-cavitation vibration device 6 through a flange, and the anti-cavitation vibration device The lower part of 6 is connected with the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com