Linear actuator and aircraft component comprising same

A technology of linear actuators and bearing parts, used in transmission parts, transmissions, aircraft transmissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

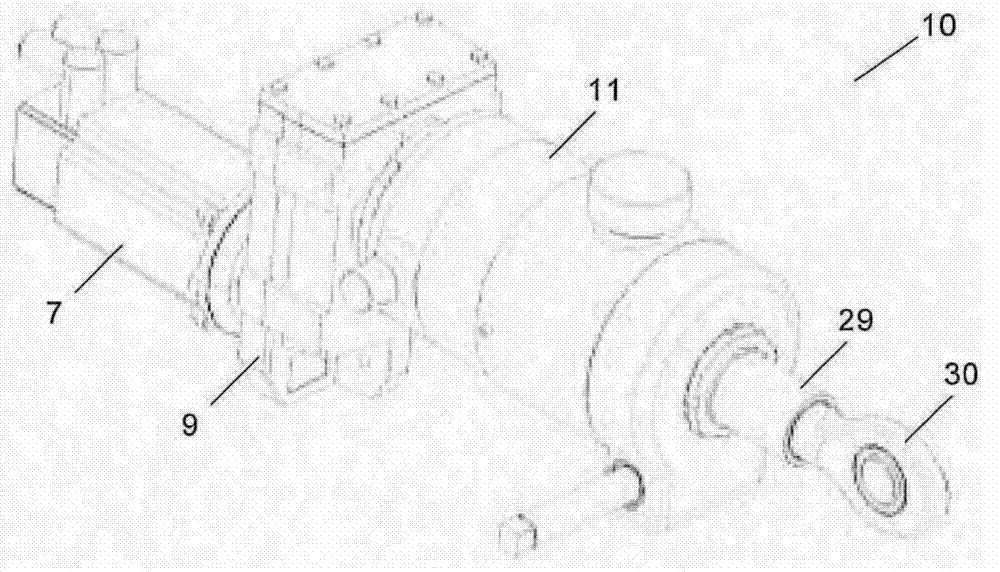

[0035] figure 1 An overview of a linear actuator 10 for linearly moving an actuator 30 according to an embodiment of the present invention, which will now be described, is shown.

[0036] For example, a set of linear actuators 10 may be used in order to actuate control surfaces of the aircraft.

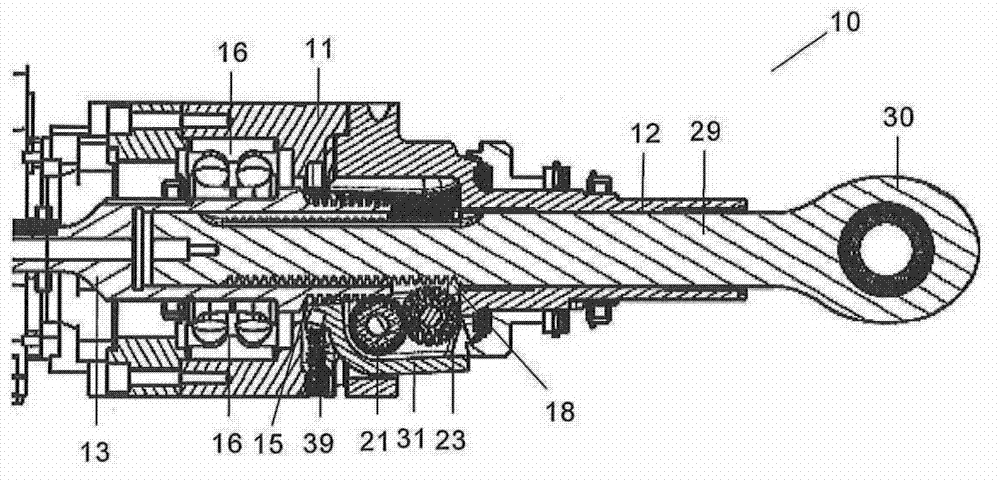

[0037] The linear actuator 10 converts the rotational motion of an input shaft (driven by an electric motor 7 through a gearbox 9 ) located within a housing 11 into a controlled linear motion of an output shaft 29 to which an actuator 30 is connected. The linear actuator 10 may be directly driven by an electric motor.

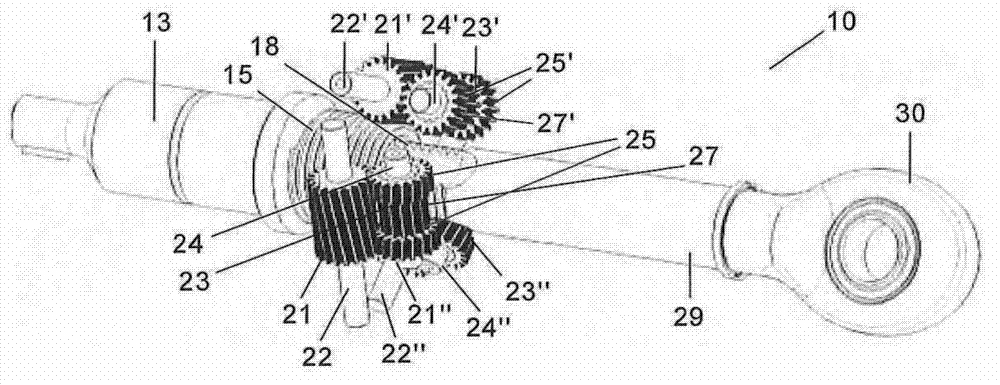

[0038] figure 2 with image 3 The main components of the linear actuator 10 are shown: input shaft 13, output shaft 29, three first helical roller gears 21, 21', 21" and three second helical roller gears 23, 23', 23" ( Although in image 3 Only the first roller gear 21, 21' and the second roller gear 23, 23' are clearly shown in the image 3 Corresponding refere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com