Mould for plastic container

A technology for plastic containers and molds, applied in the field of molds for plastic containers, can solve the problems of deformation of plastic parts, difficult demoulding action, unreliability, etc., and achieve the effects of improving performance, improving injection molding production efficiency, and improving surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

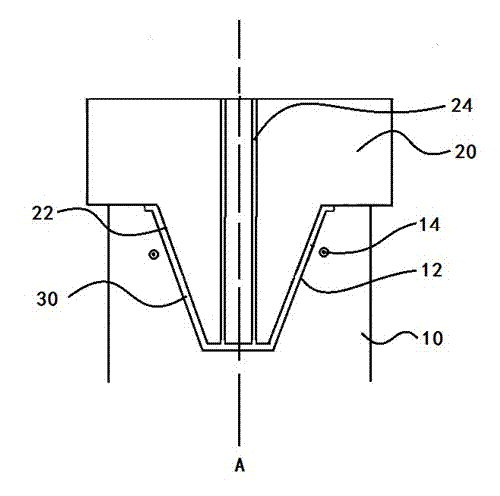

[0018] Such as figure 1 As shown, the mold for the plastic container described in this embodiment, the ratio of the depth of the plastic container to the bottom diameter of the container is equal to 2, and it includes a movable mold 10 with a cavity 12 and a fixed mold 20 containing a core 22 , the core 22 is in a convex shape corresponding to the inner surface of the plastic container, the cavity 12 is in a concave shape corresponding to the outer surface of the plastic container, and the cavity 12 and the core 22 meet to form the shape of the plastic container molding cavity 30, and the fixed mold 20 has a vertical injection pipe 24 extending from its upper surface to its lower surface, and the movable mold 10 has a magnetic induction heating coil 14 along the periphery near the top of the cavity 12 . Wherein the movable mold and the fixed mold are casted by self-lubricating alloy steel, and the chemical composition of the self-lubricating alloy steel is as follows: 0.20wt%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com