Suspended gold wire ball bonding workbench

A technology of gold wire ball bonding and worktable, applied in metal processing equipment, manufacturing tools, welding equipment, etc., can solve the difficulties of chip positioning, loading and unloading heating and adjustment, gas-sensitive chip positioning, clamping and heating difficulties, chip physics Damage and other problems, to achieve the effect of convenient disassembly and orientation adjustment, ingenious structure and size design, and small physical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

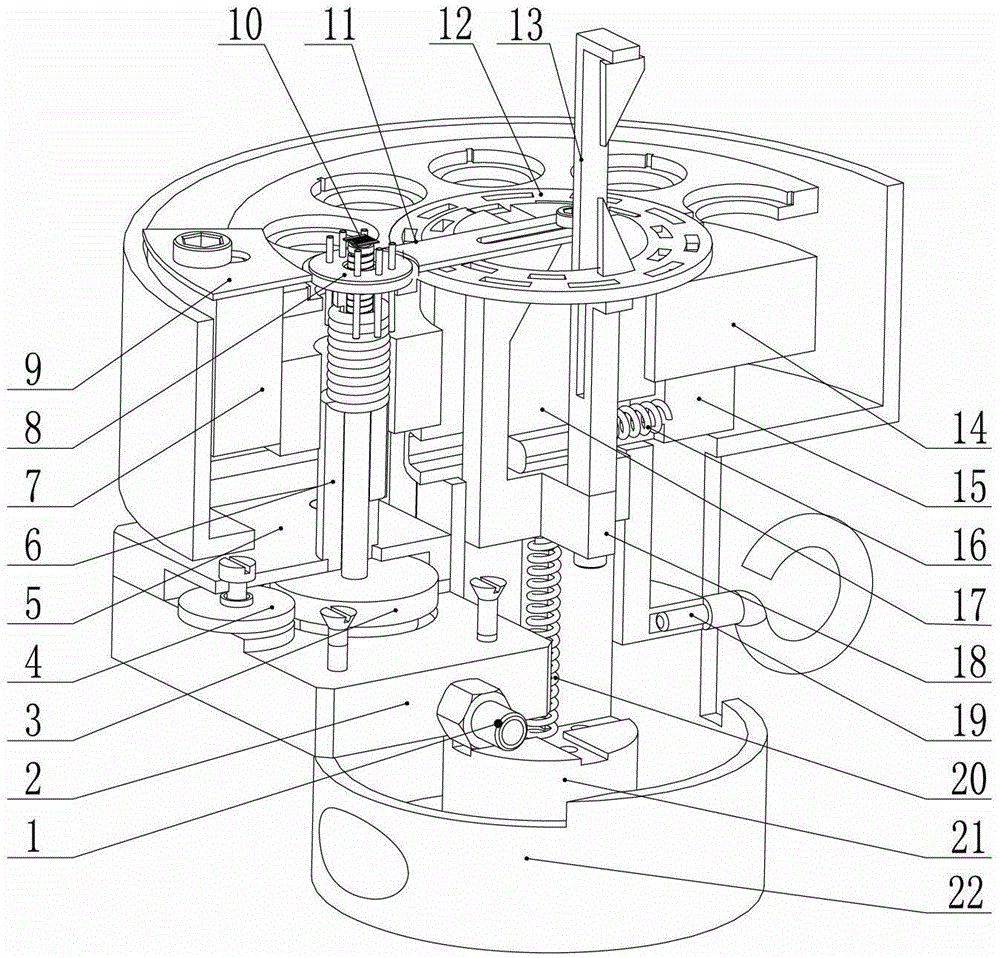

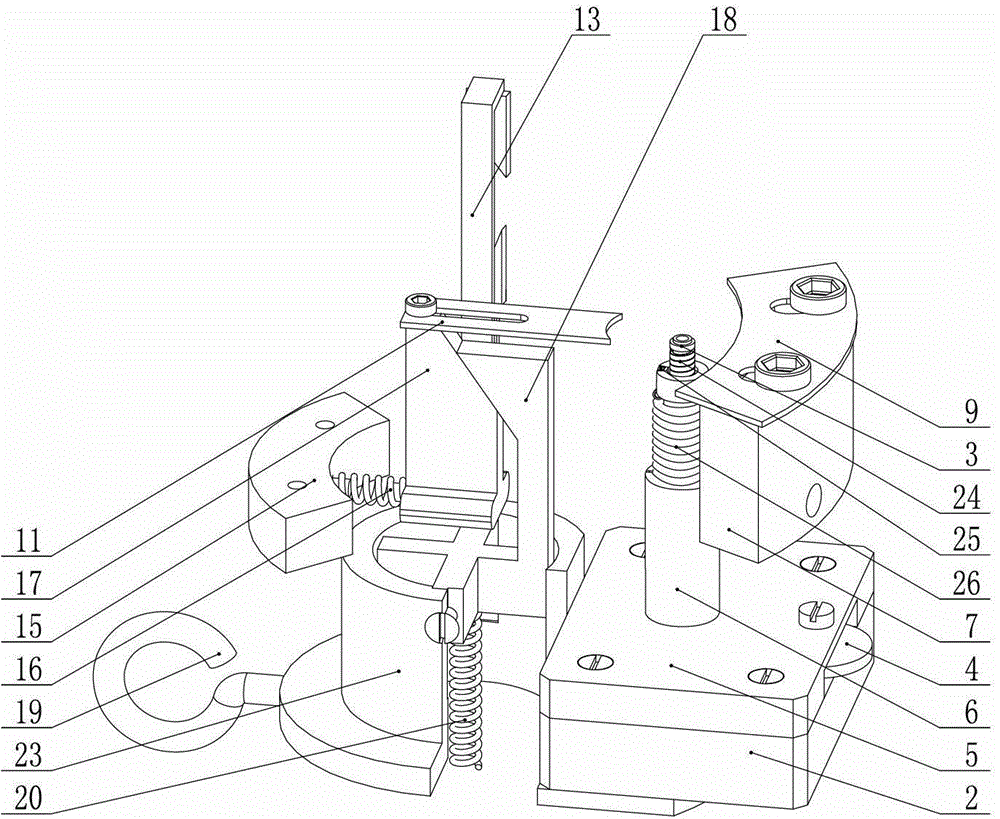

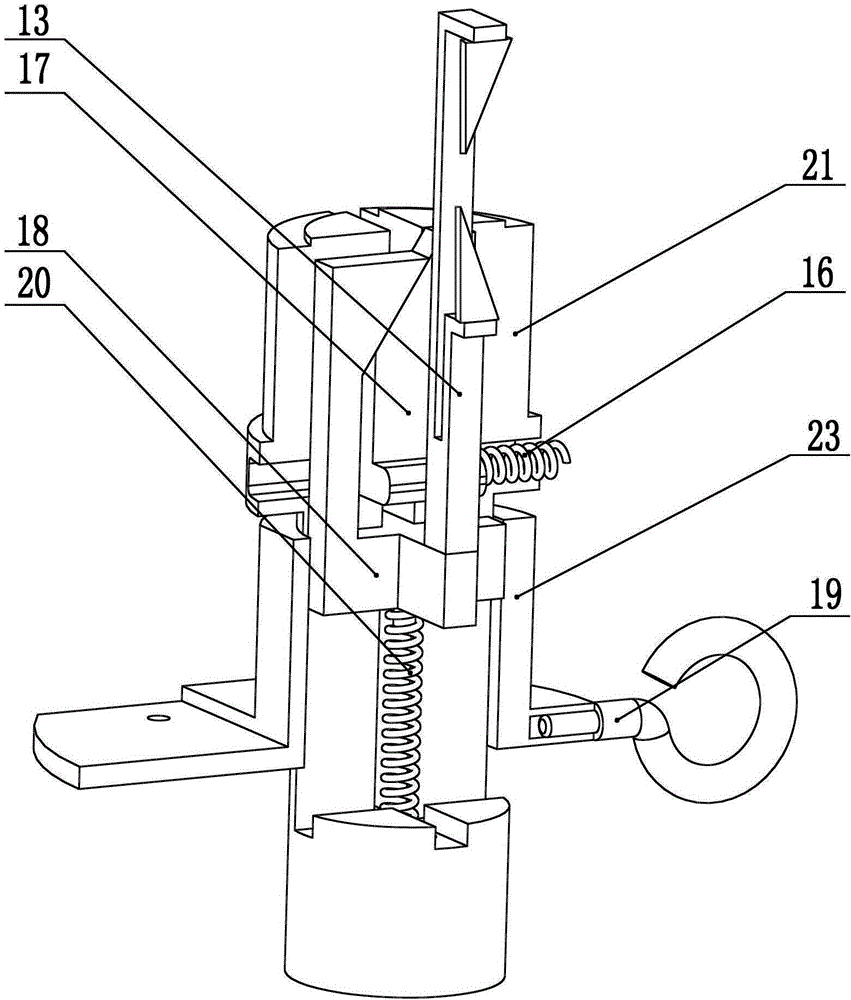

[0033] More specifically, as figure 1 , Figure 12 , Figure 5 , Figure 13 and Figure 14 As shown, the gas sensor gas sensor chip suspended gold wire ball welding workbench described in this embodiment includes a shell 22, which is connected to the central column 21 by four screws in the center of the shell; Vertical chute 44, the upper part is provided with horizontal chute 43, and is provided with the supporting platform of two layers of different diameters, and the large-diameter supporting surface place of the lower side of the outer facade of the central column is provided with the lower boss 50 of the central column; A pressing block 18 is set in the straight chute, a slider 17 is set in the horizontal chute, a lifting plate 14 is set above the lower boss 50 of the center column, and an upper boss of the center column is set at the small-diameter support surface on the upper side. 45, the boss 45 on the center column cooperates with the positioning hole 49 provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com