Fiber core cutting and assembly device of fiber wiring terminal

A technology for connecting terminals and assembling devices, which is applied to the coupling of optical waveguides, light guides, optics, etc., can solve the problems of optical fiber flatness and end surface finish being difficult to guarantee, and achieves less physical damage, improved assembly success rate, and improved straightness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

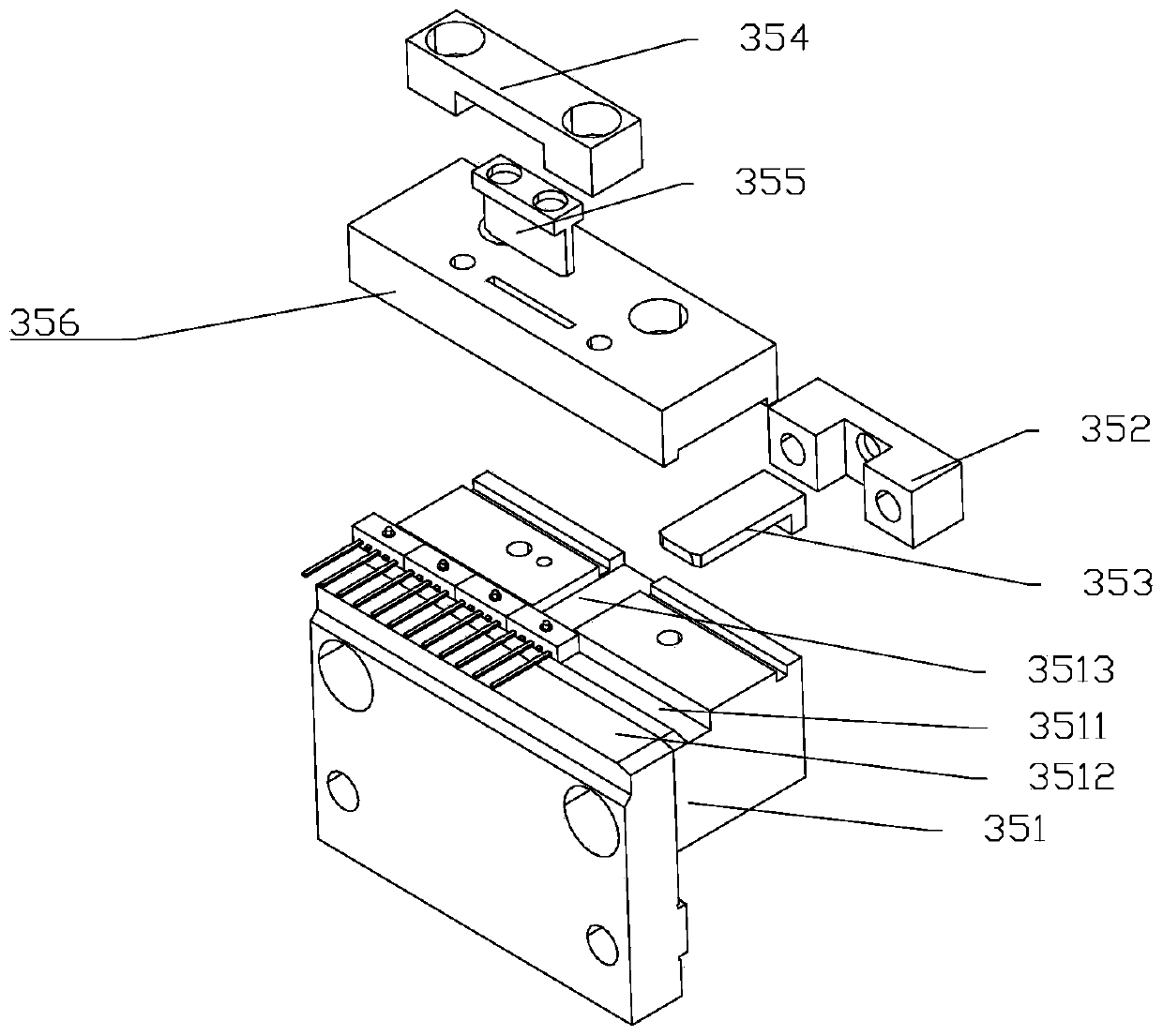

[0016] Such as figure 1 As shown, an optical fiber core cutting and assembly device for an optical fiber terminal includes a frame and a base 31 mounted on the frame, an optical fiber core feeding assembly 32, a first removal mechanism 33, a second removal mechanism 34, a transition The chute assembly 35, the third removal mechanism 36, the fourth removal mechanism 37, the pushing mechanism 38, the cutting mechanism 39 and the collection box 310; the base 31 is fixedly arranged on the frame, and the panel of the base 31 has holes , the base 31 is provided with a collection box 310; the optical fiber core feeding assembly 32 is located on the side of the base 31 and is connected with the first removal mechanism 33, the first removal mechanism 33 is installed on the base 31, and the second removal mechanism 33 The taking mechanism 34 is orthogonal to the first taking mechanism 33, the third taking mechanism 36 is connected with the transition chute assembly 35, the transition ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com