Iron ore-containing heavy oil hydrogenation catalyst, and preparation method and application thereof

A heavy oil hydrogenation and catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, petroleum industry, etc. Catalytic effect, good dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

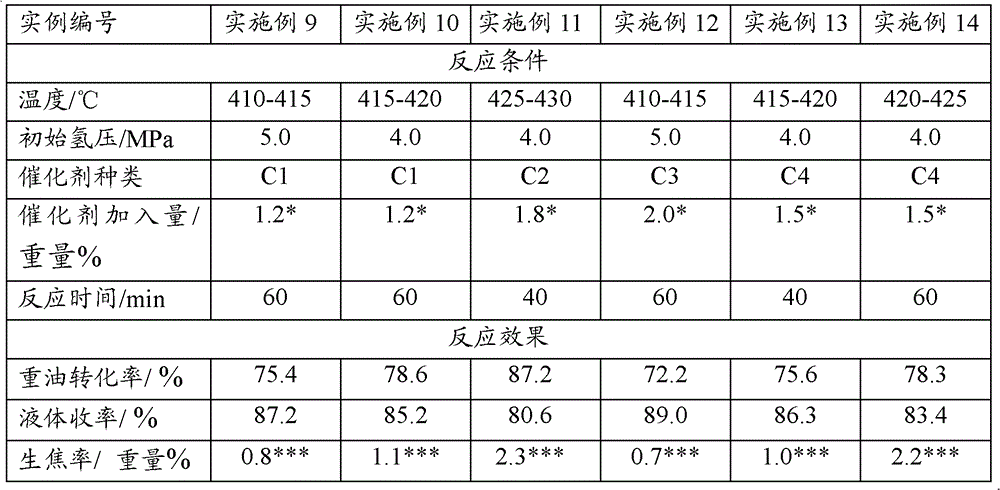

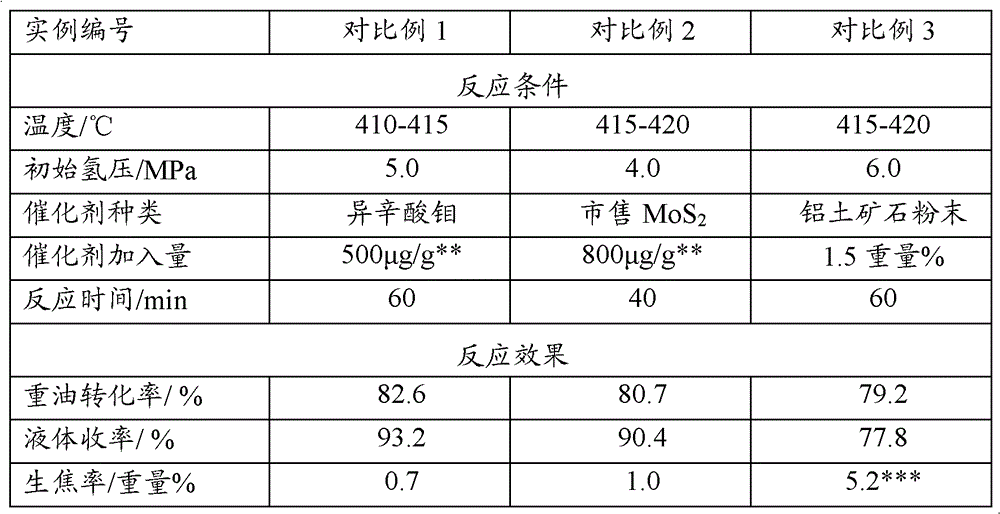

Examples

Embodiment 1

[0034] Weigh 38 g of diesel oil, add 1.0 g of organic bentonite (domestic, organic matter content 15-20% by weight), and homogenize with a shearing machine. Then heated and stirred on an 80° C. oil bath for 2 hours. The obtained homogeneous mixed oil was cooled to room temperature, 0.5 g of PEG 600 was added, and 0.2 g of sodium dodecylbenzenesulfonate was added, and homogenized at room temperature to obtain dispersion medium A.

Embodiment 2

[0036]Weigh 42 g of kerosene, add 0.8 g of fumed silica (particle size less than 1 μm), and homogenize with a shearing machine. At room temperature, 0.2 g of sodium oleate, 0.4 g of PEG2000, and 1.0 g of analytically pure ethanol were added. Homogenize at room temperature to obtain dispersion medium B.

Embodiment 3

[0038] Weigh 30 g of diesel oil, 12 g of white oil, and add 1.2 g of organic bentonite (domestic, organic matter content 15-20% by weight). Homogenization is performed on a shearing machine. At room temperature, add 0.2 g of sodium oleate, add 0.4 g of OP-7, and add 1.0 g of analytically pure ethanol. Homogenize at room temperature to obtain dispersion medium C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com