Glass bottle defect detection device and image splitting device

A technology for defect detection and glass bottles, which is applied in the direction of optical defect/defect, optics, instruments, etc., can solve the problems of uneven stress, large chance, low detection speed, etc., and achieve high detection accuracy, fast detection speed, and detection low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

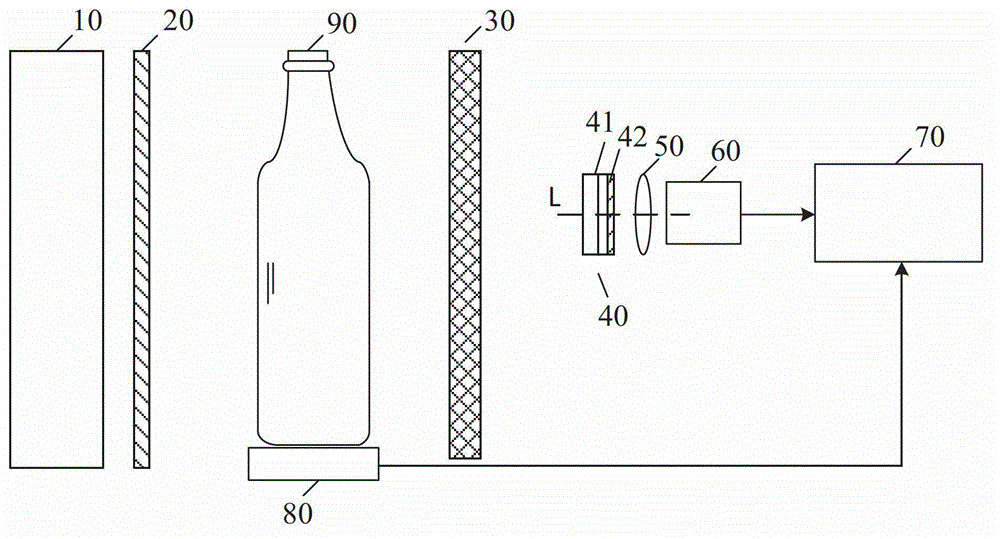

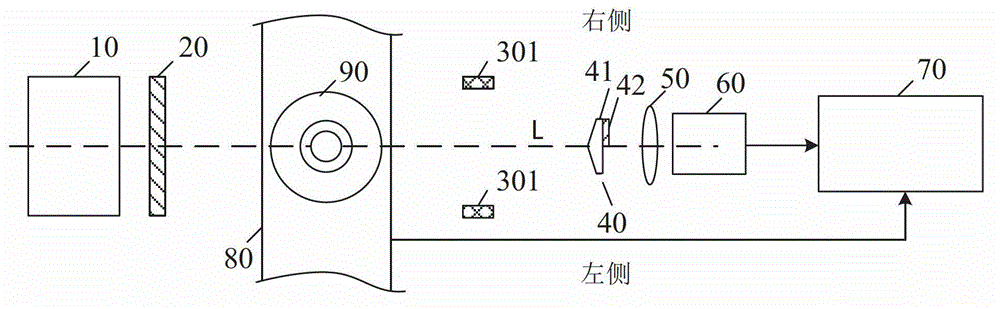

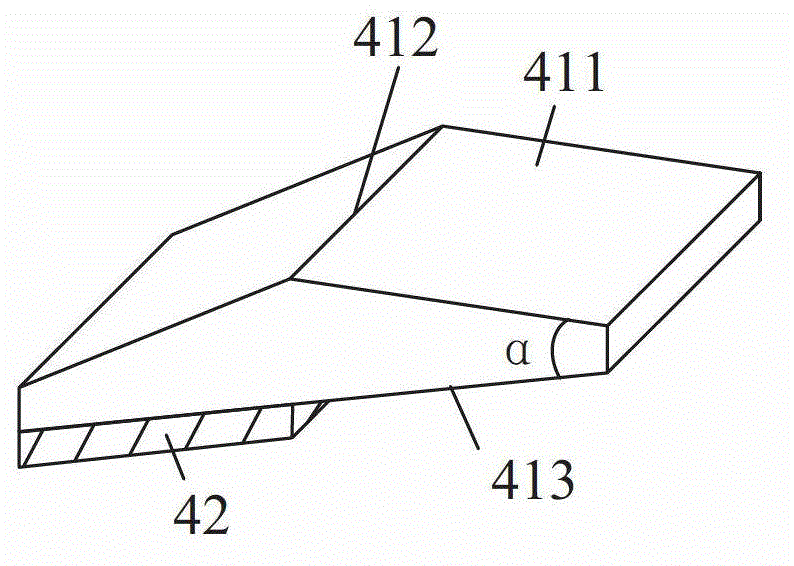

[0023] Such as Figure 1 to Figure 3 As shown, the glass bottle defect detection device of the present invention includes a surface light source 10, a polarizer 20, a diaphragm 30, an image splitting device 40, a lens 50 and a camera 60, the front of the surface light source 10 is provided with the polarizer 20, the An aperture 30 is provided in front of the polarizer 20, and the glass bottle 90 to be detected is located between the polarizer 20 and the aperture 30, and the image splitting device 40 is arranged in sequence from near to far in front of the aperture 30 , the lens 50, the camera 60, the lens of the camera 60 is arranged towards the lens 50, the image splitting device 40, the lens 50, and the camera 60 are coaxially arranged, wherein: the image splitting device 40 includes a Fresnel double prism 41, the two obliquely intersecting incident planes 411 of the Fresnel double prism 41 face the aperture 30 and are arranged corresponding to the position to be detected on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com