A centrifugal analysis method for oil shale samples

A centrifugal analysis and rock sample technology, applied in the direction of analyzing materials, measuring devices, instruments, etc., can solve the problems of large error and low efficiency, and achieve the effect of small error, high efficiency and reasonable setting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

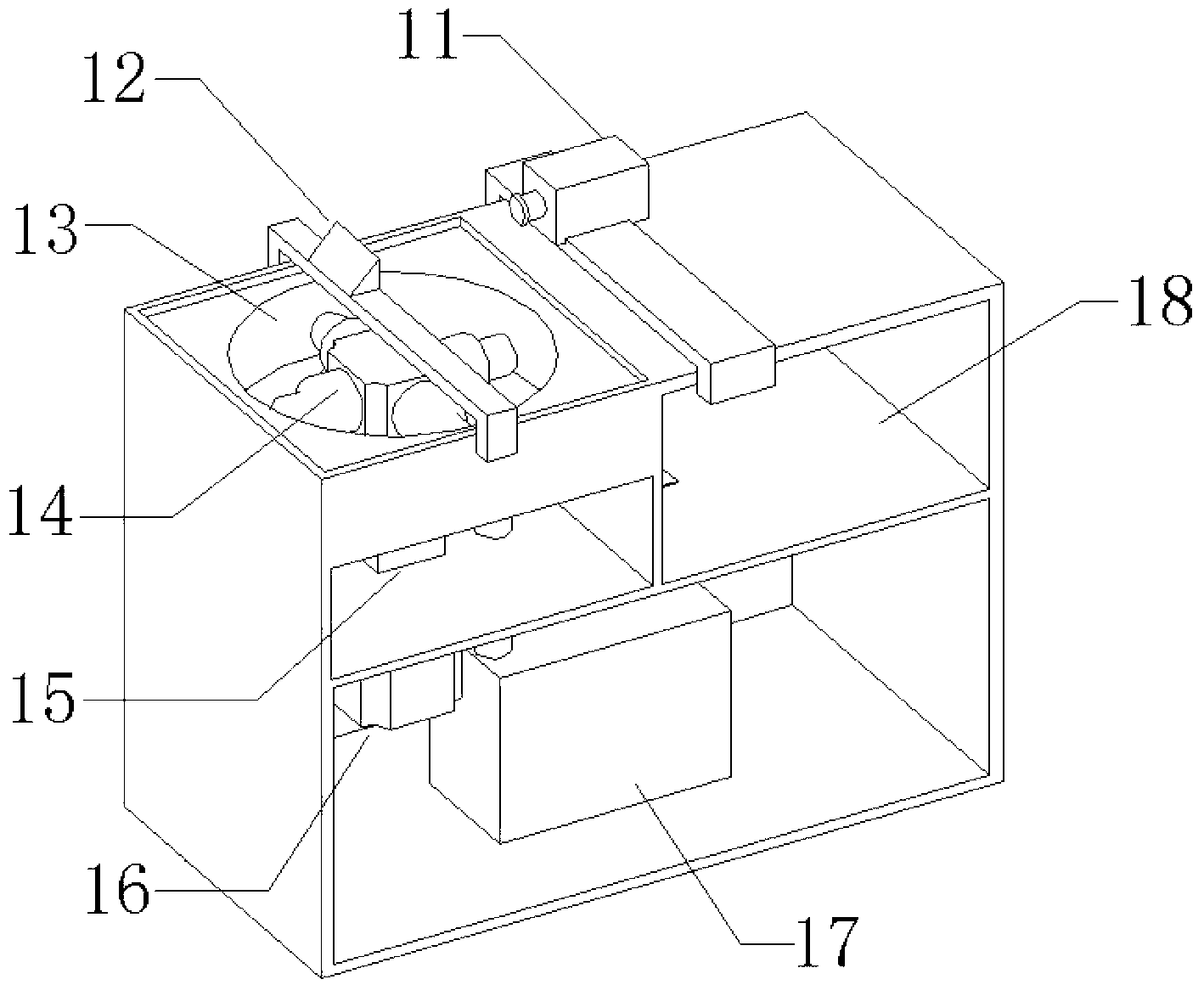

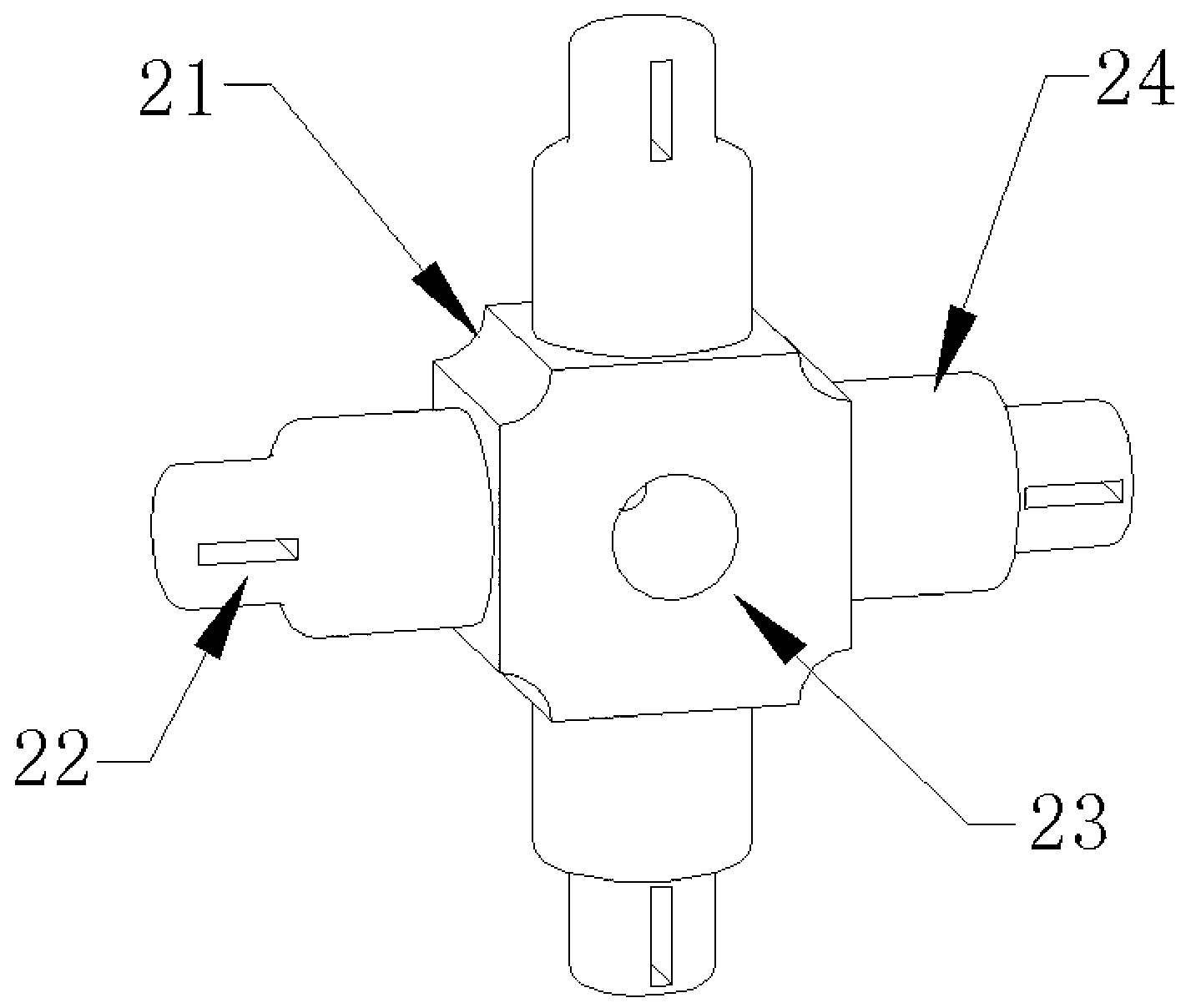

[0027] For the purpose of full disclosure, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described below are only used to explain the present invention, and are not used to limit the protection scope of the present invention.

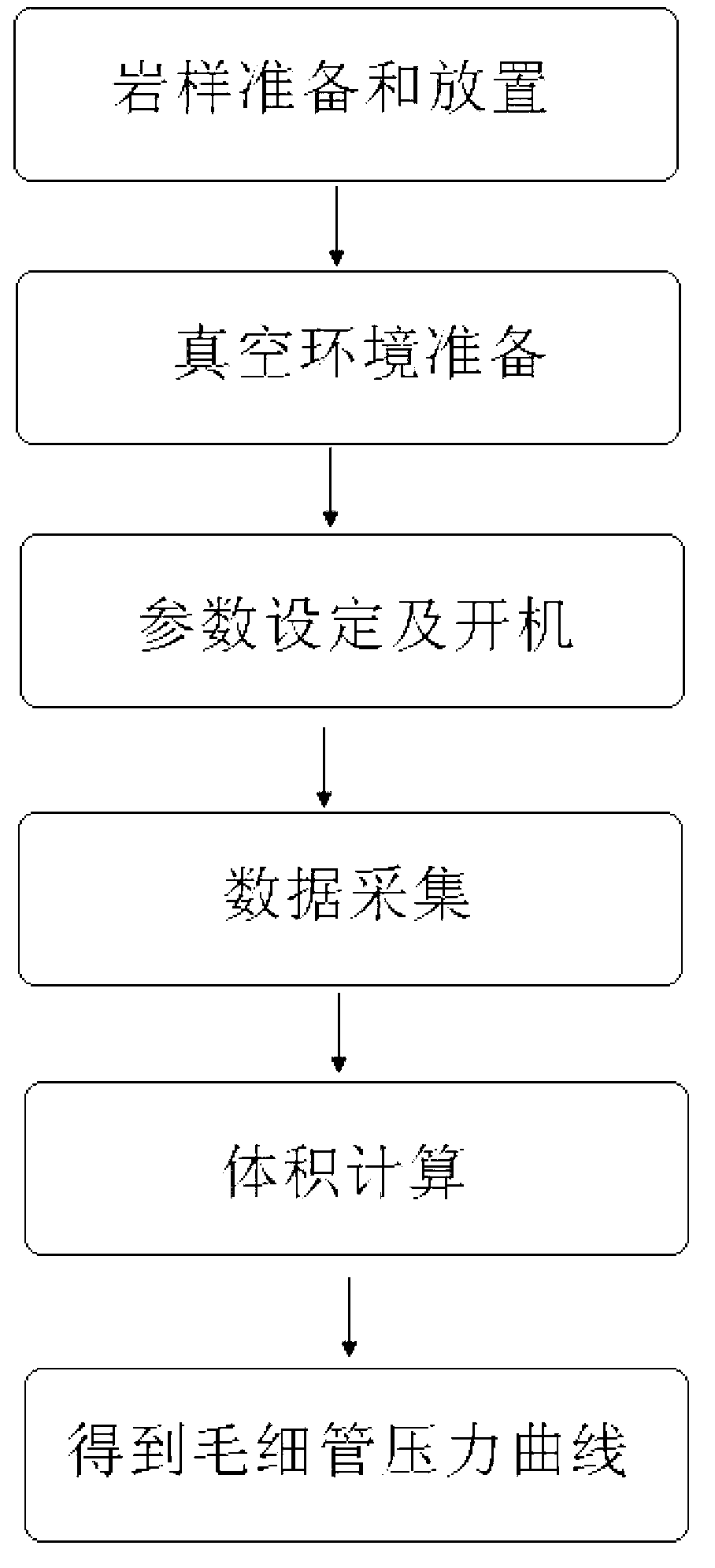

[0028] Such as figure 1 As shown, the present invention provides a method for centrifugal analysis of petroleum rock samples, including the following steps: 1) rock sample preparation and placement: put the prepared rock samples into centrifugal cups (add oil or water as required), and then Install the centrifuge cup on the rotor in the centrifuge chamber;

[0029] 2) Vacuum environment preparation: close the door of the centrifuge chamber and turn on the vacuum pump to make the inside of the centrifuge chamber vacuum;

[0030] 3) Parameter setting and start-up: start the frequency conversion motor, and set the speed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com