In-situ direct shear tester for soil bodies

A direct shear tester, an in-situ technology, is used in the direction of applying a stable shear force to test the strength of materials, which can solve problems such as difficult to control drainage conditions, small shearing surface of soil samples, and difficulty in ensuring consistent and uniform soil samples. problems, to achieve reliable results, accurate testing, and flexible operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

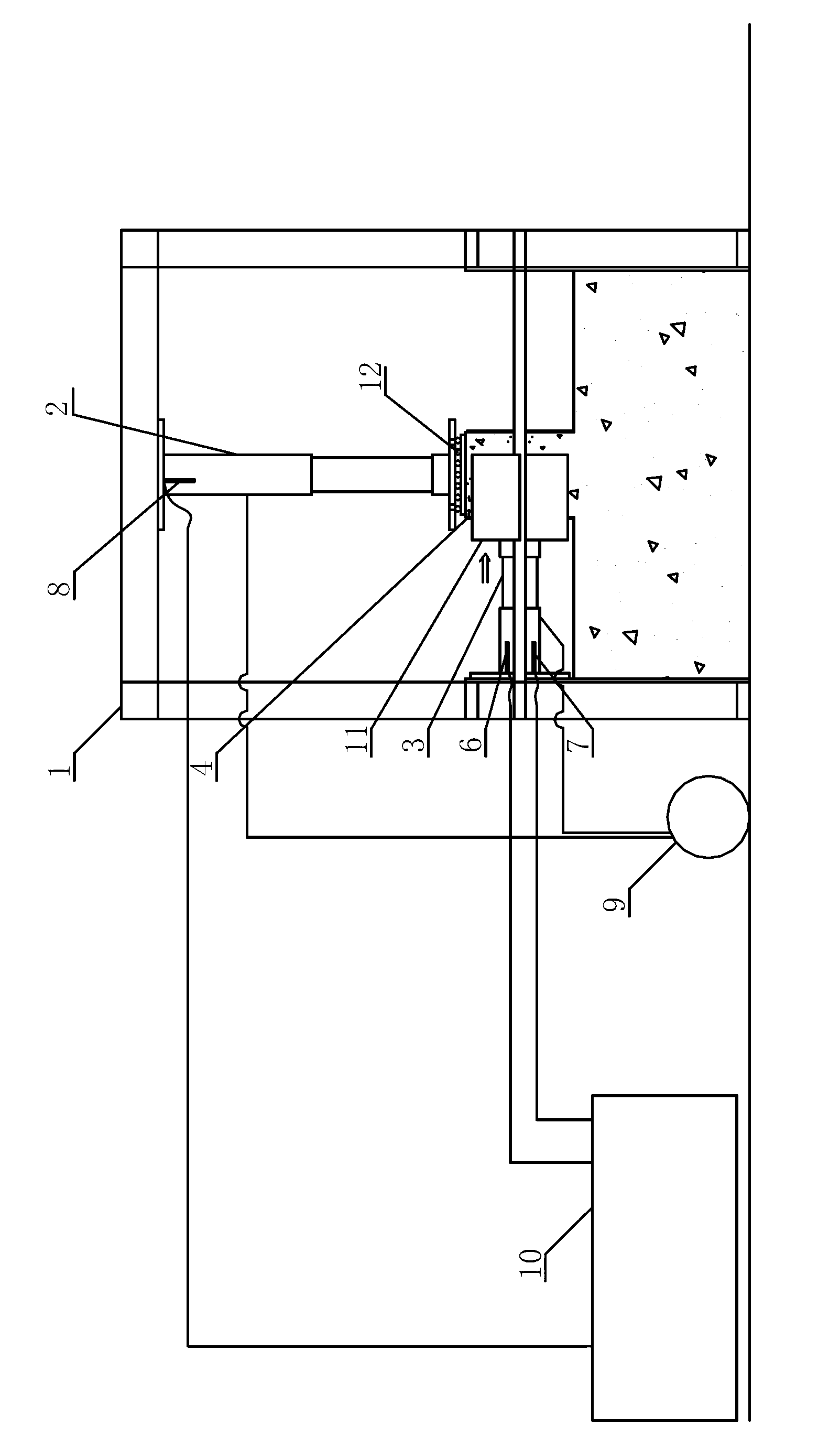

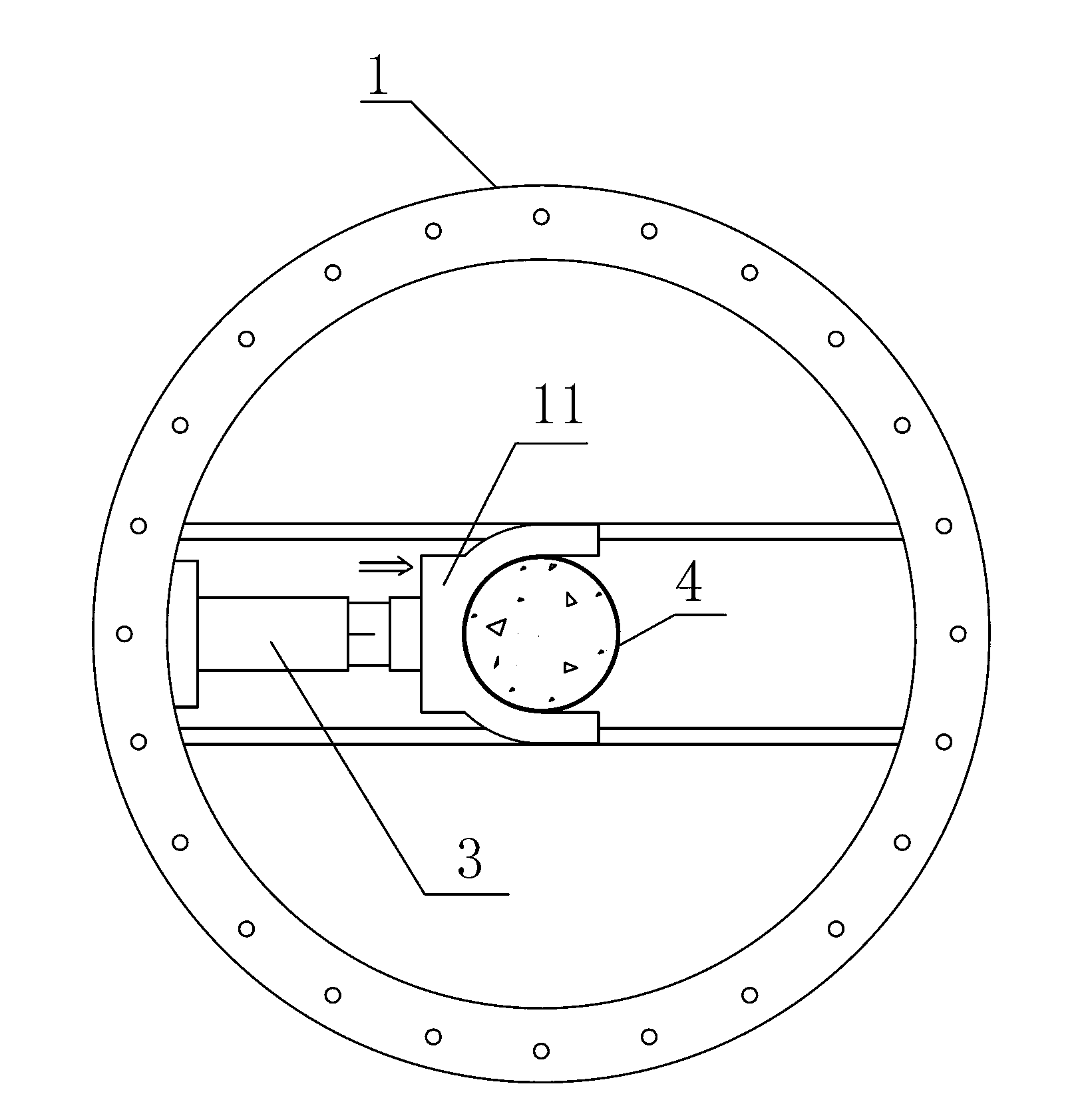

[0017] Such as figure 1 , 2 As shown, the present invention includes: a steel frame 1, a vertical oil cylinder 2, a horizontal oil cylinder 3 and a cylinder 4. The vertical oil cylinder 2 is arranged on the steel frame 1, and the cylinder 4 is arranged on the power output end of the vertical oil cylinder 2 through the horizontal slide rail 12 to be movable horizontally; the horizontal oil cylinder 3 is arranged on the steel frame 1; the push bowl 11 is arranged on the horizontal oil cylinder 3 The power output end of the cylinder 4 is used to apply a horizontal thrust to the cylinder 4 and move the cylinder 4 a predetermined distance to shear the soil inside the cylinder 4 and the soil outside the cylinder 4.

[0018] In addition, a displacement sensor 6 for measuring the displacement of the soil and a first pressure sensor 7 for measuring the thrust of the soil are also arranged on the horizontal oil cylinder 3, and a pressure sensor 7 for measuring the simulated side pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com