Shaft seal of oil seal machinery

A mechanical shaft and oil sealing technology, applied in the direction of mechanical equipment, engine seals, engine components, etc., can solve the problems of dry grinding, short service life of materials, easy leakage, etc., to overcome the phenomenon of dry grinding, simple structure, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

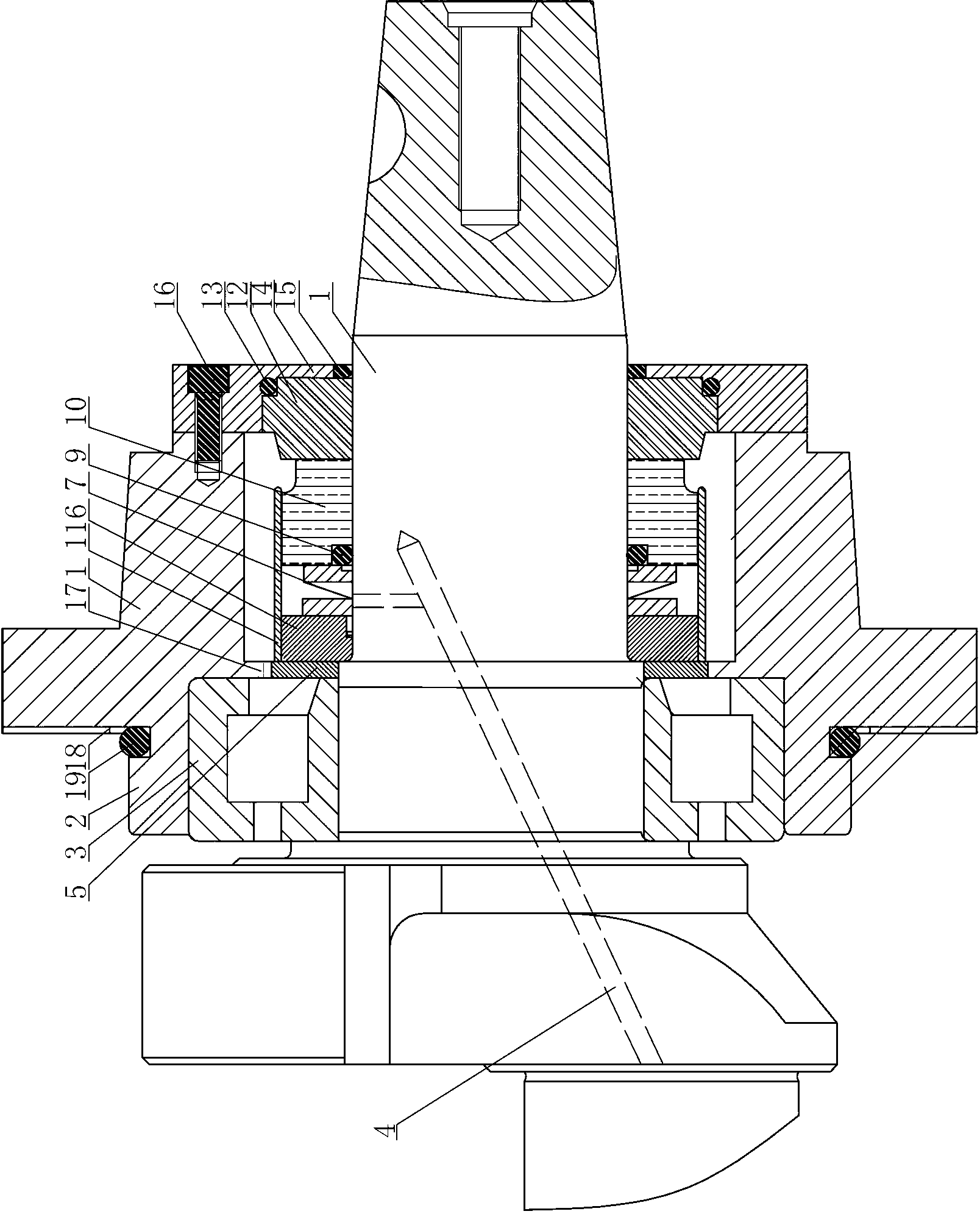

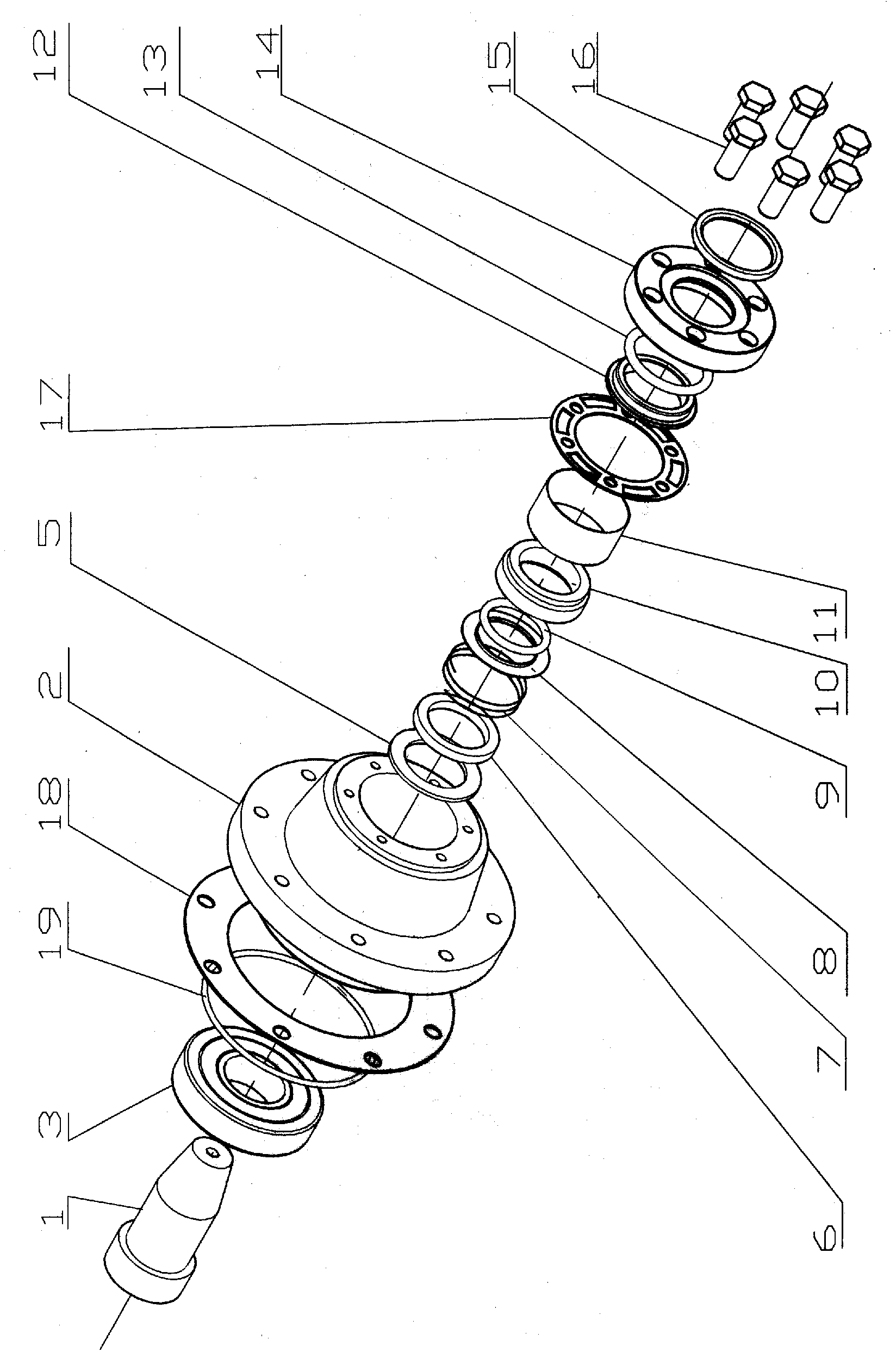

[0014] Depend on Figure 1 to Figure 2 It can be seen that the present invention includes crankshaft 1, front bearing housing 2, dynamic friction ring assembly and static friction ring assembly, wherein:

[0015] The middle of the front bearing seat 2 is a cavity, and the crankshaft 1 is interspersed in the cavity of the front bearing seat 2 through the bearing 3. There is an oil passage 4 in the shaft, and an oil baffle plate 5 is arranged on the right end surface of the bearing 3 to prevent oil The inner diameter surface of the plate 5 is attached to the crankshaft 1, the right end of the oil baffle plate 5 is provided with a dynamic friction ring assembly, and the right end of the dynamic friction ring assembly is provided with a static friction ring assembly, and the oil baffle plate 5 and the static friction ring assembly are in the cavity of the front bearing housing 2 form an annular oil pool;

[0016] The oil outlet of the above-mentioned oil passage 4 is opened on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com