Gearbox for field operation machine

A technology for operating machinery and gearboxes, which is applied to mechanical equipment, gear transmissions, belts/chains/gears, etc., and can solve problems that affect operating efficiency, cumbersome braking devices, and difficulty in improving bearing capacity and passing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

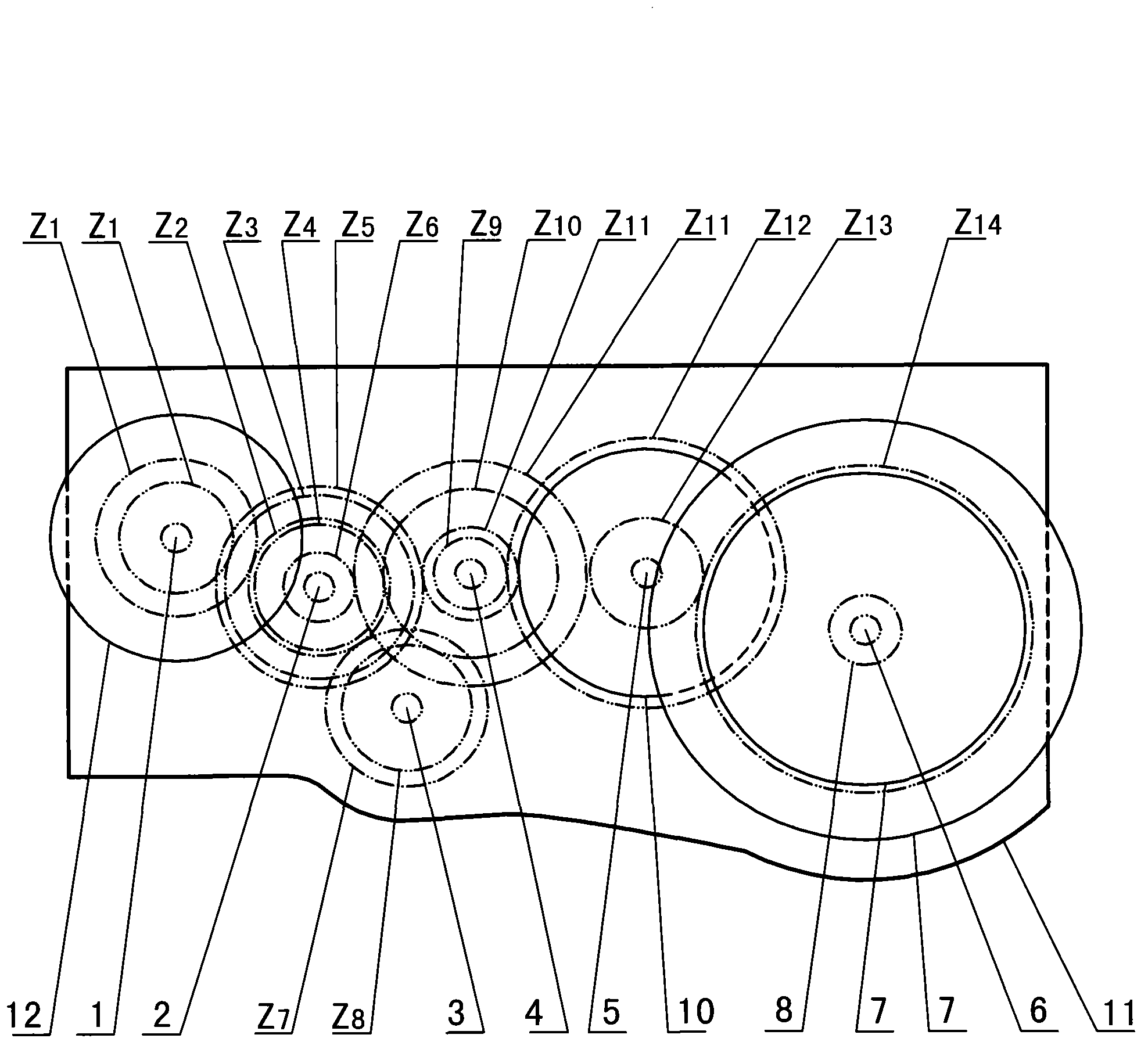

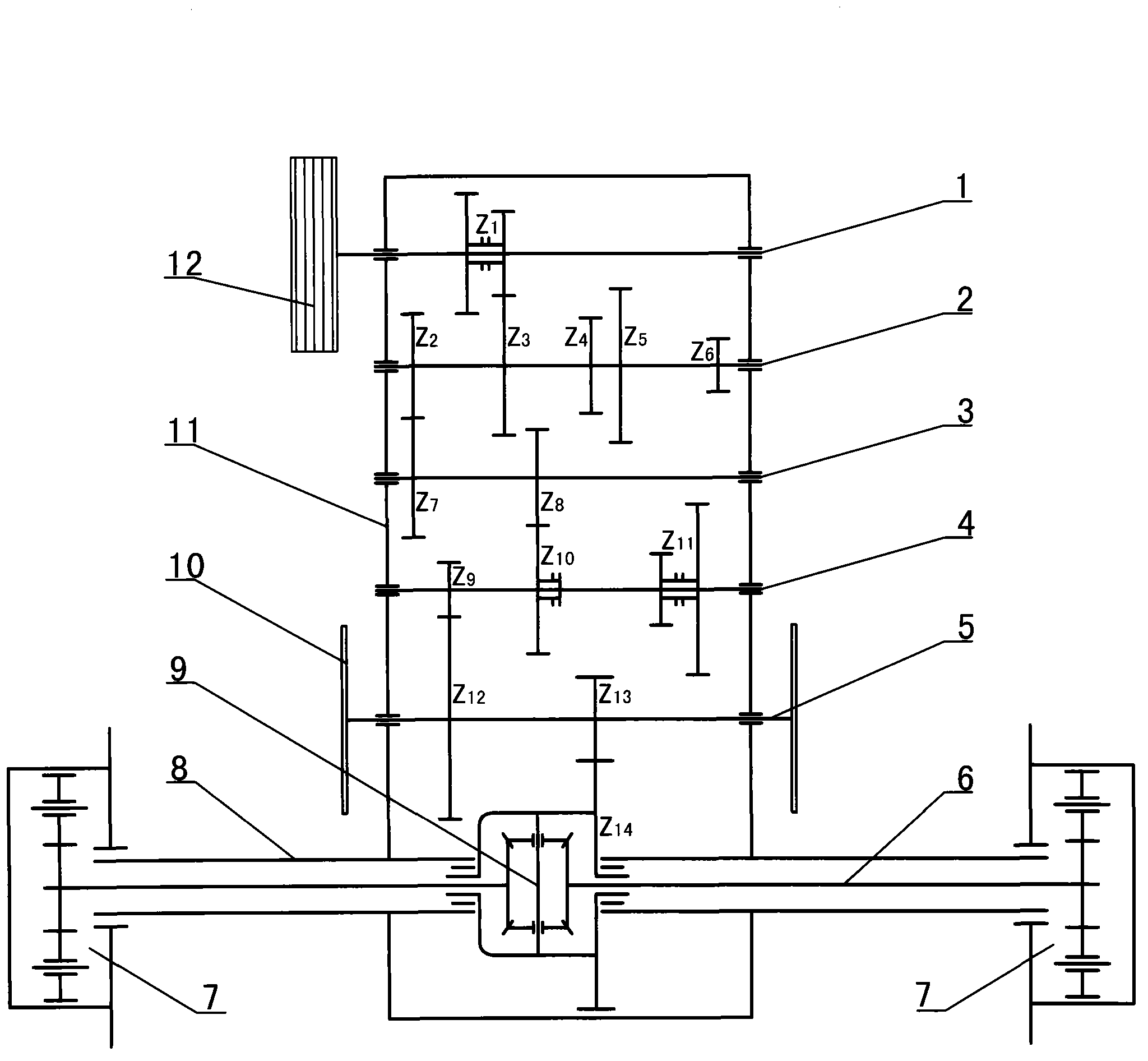

[0008] The present invention has one shaft (1), two shafts (2), reverse gear shaft (3), four shafts (4), five shafts (5), left and right half shafts installed in parallel on the gearbox housing (11) shaft (6). One shaft (1) stretches out clutch (12) is housed at an end outside the gearbox casing (11), and clutch (12) is input power to gearbox with higher rotating speed, and one shaft (1) is rotated. Inside the gearbox, a slidable high and low gear sliding gear (Z 1 ), high-speed driven gears (Z 2 ), low-speed driven gear (Z 3 ), second gear driving gear (Z 4 ), third gear driving gear (Z 5 ), first gear driving gear (Z 6 ), the high and low gear sliding gears on one shaft (1) (Z 1 ) can slide left and right with the high-speed driven gear (Z) on the two shafts (2) respectively 2 ) and low-speed driven gear (Z 3 ) connection to realize high and low gear conversion, and simultaneously drive two shafts (2) to rotate. On the reverse gear shaft (3), the reverse gear transm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com