High-bearing-capacity cycloidal pin wheel speed reducer

A pin wheel reducer, bearing capacity technology, applied in the direction of gear transmission, belt/chain/gear, components with teeth, etc., can solve the problems of poor pin stiffness, low bearing capacity, noise, etc. The effect of increasing stiffness, increasing bearing capacity, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

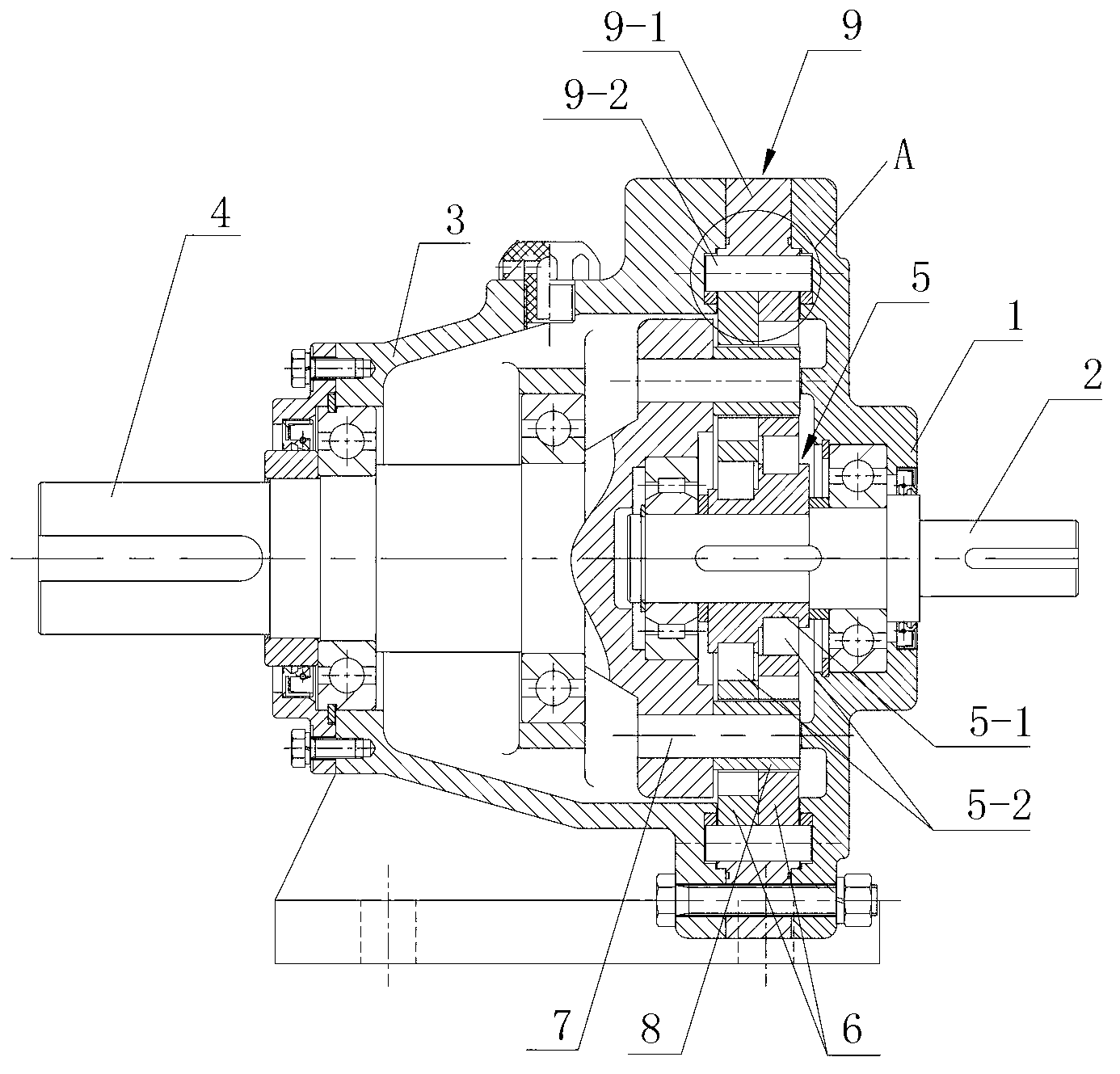

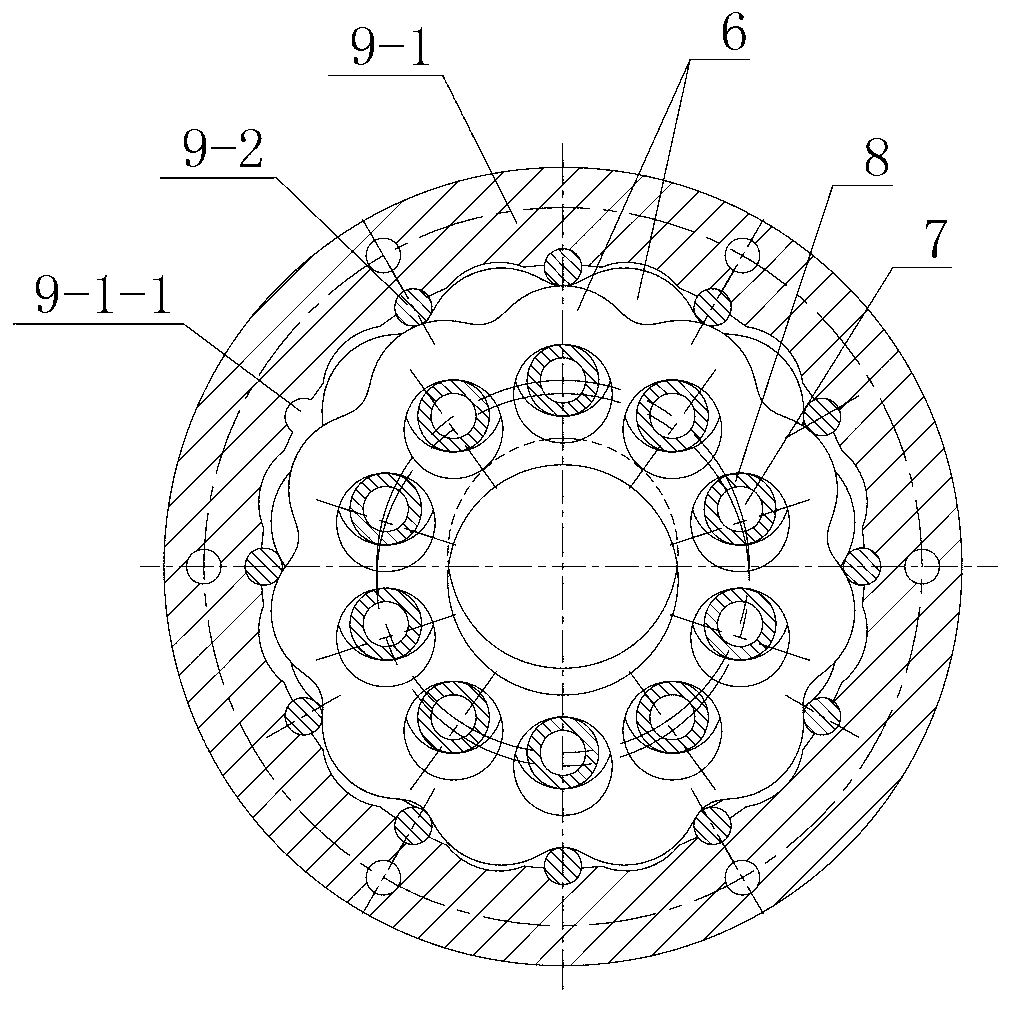

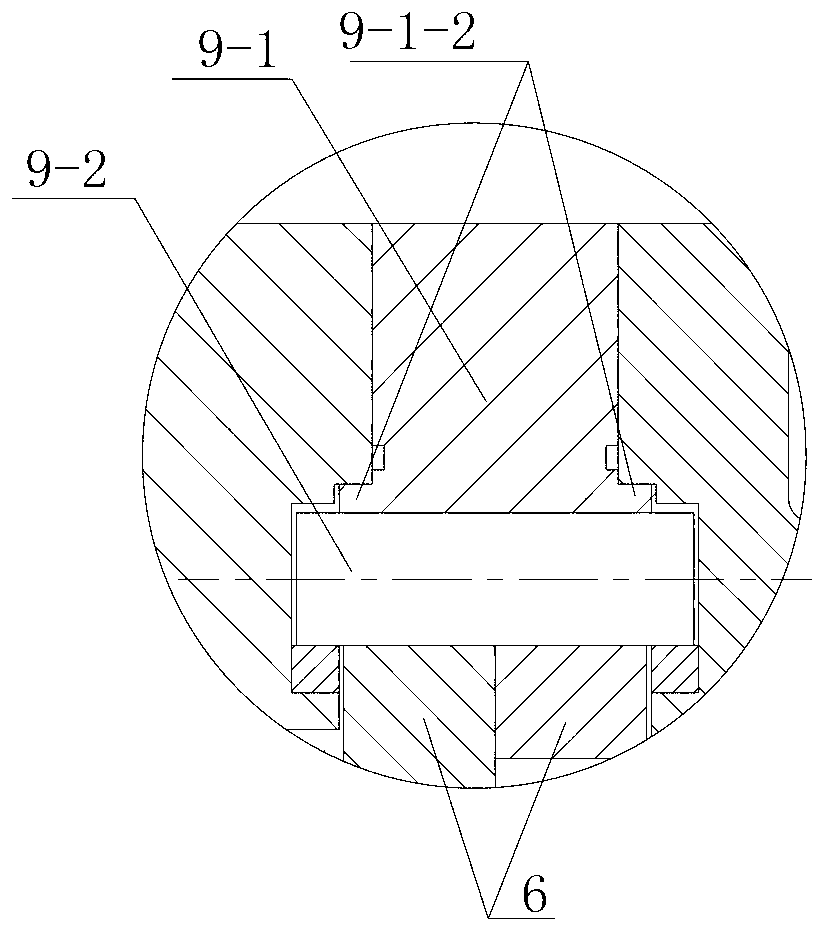

[0017] See Figure 1-3 , A high-capacity cycloid pinwheel reducer, including an input part, a deceleration part and an output part. The input part includes a flange 1 and an input shaft 2, and the input shaft is rotatably supported on the flange through a bearing. The output part includes a base 3 and an output shaft 4, and the output shaft is rotatably supported on the base through a bearing. The deceleration part includes a double eccentric support 5 that is displaced by 180°, two cycloidal wheels 6 sleeved on the double eccentric support, a plurality of pin shafts 7 and pin sleeves arranged along the circumference of the two cycloidal wheels and the output shaft. 8. Needle tooth assembly 9 matched with the outer tooth surface of the cycloid. Specifically, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com