Structure for cooling engine silencer

An engine and muffler technology, applied in the direction of engine cooling, engine components, machines/engines, etc., can solve the problems of reducing the service life of the engine, wear of core components, etc., to reduce the temperature of the whole machine, reduce the temperature, and improve the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

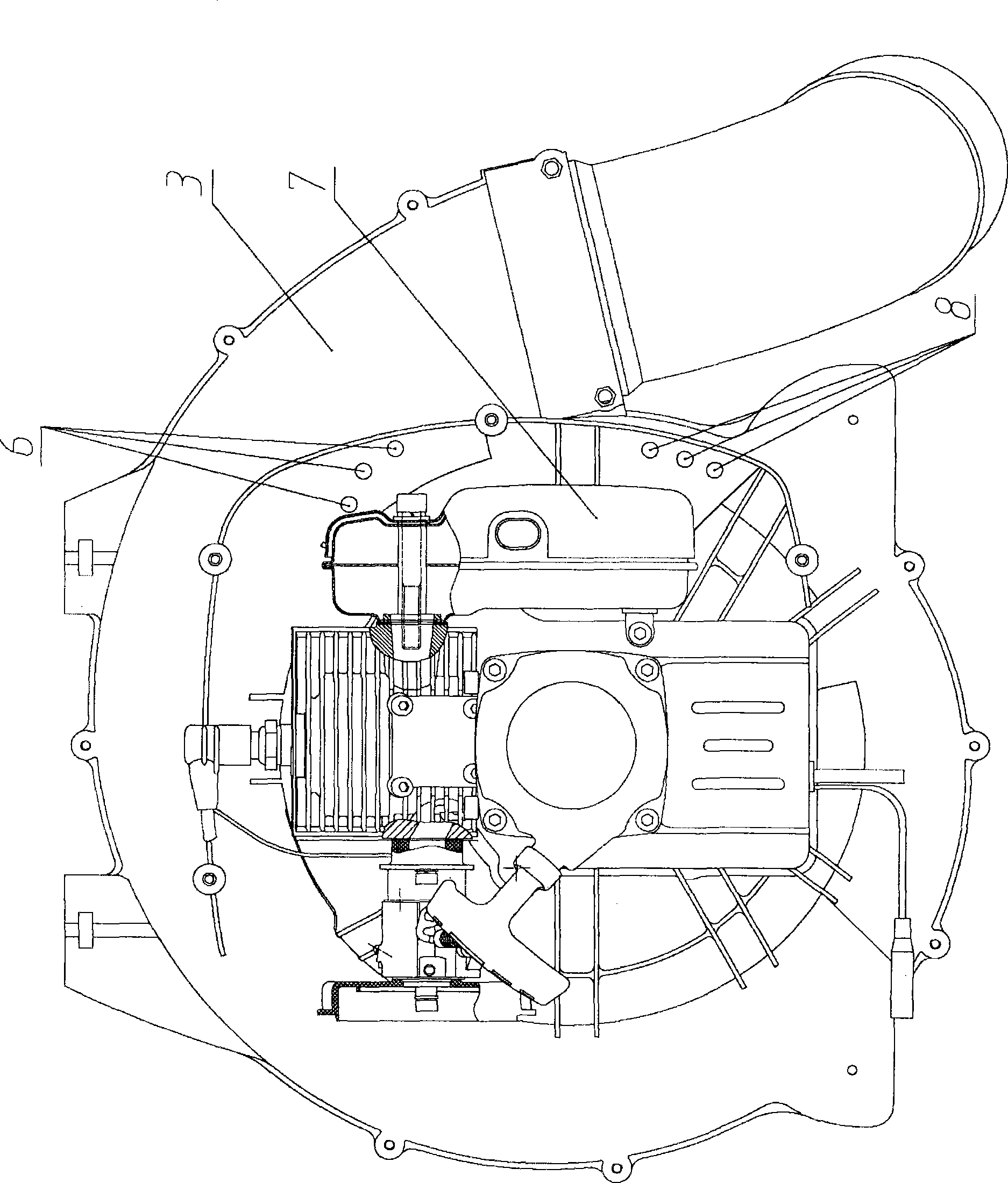

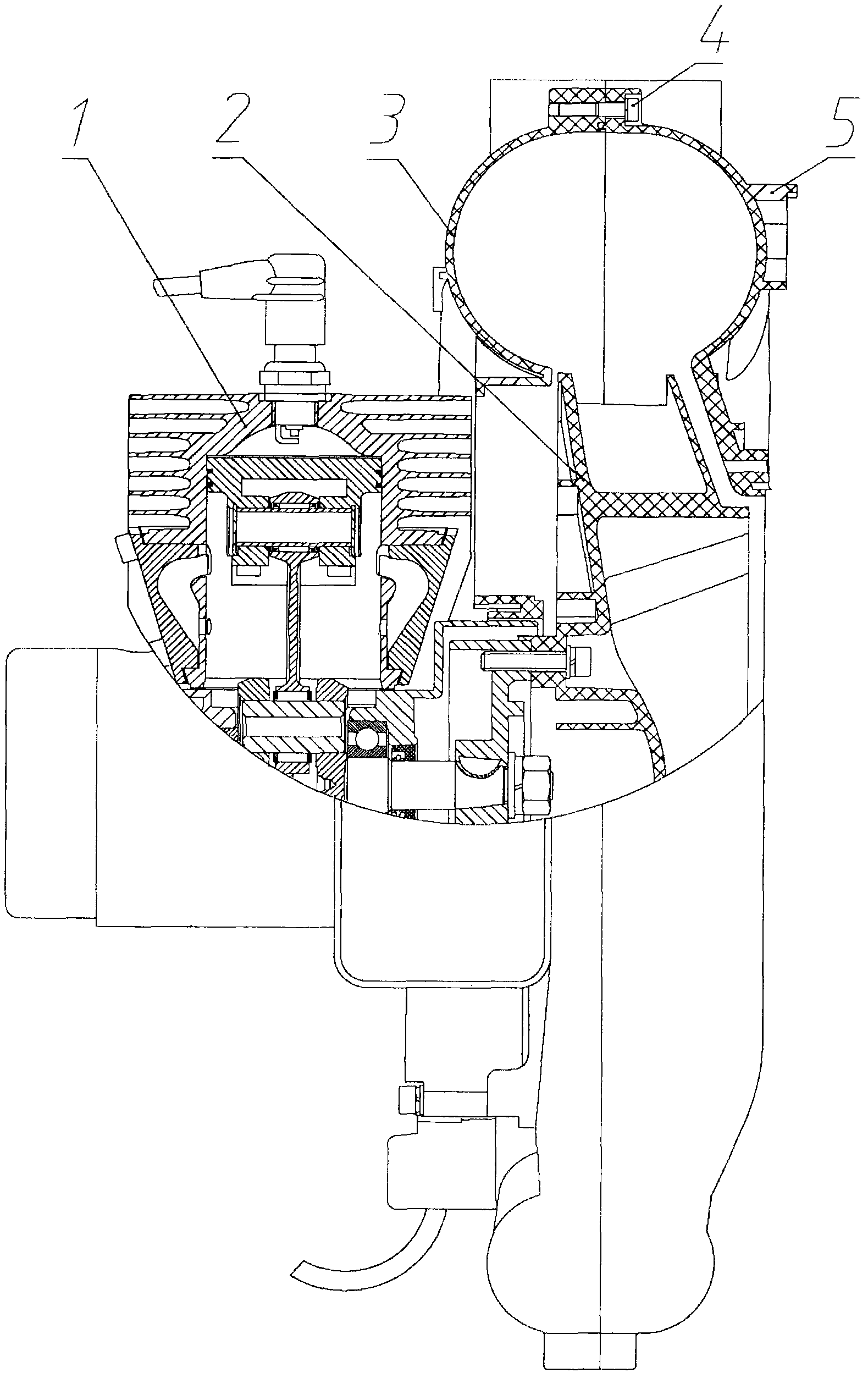

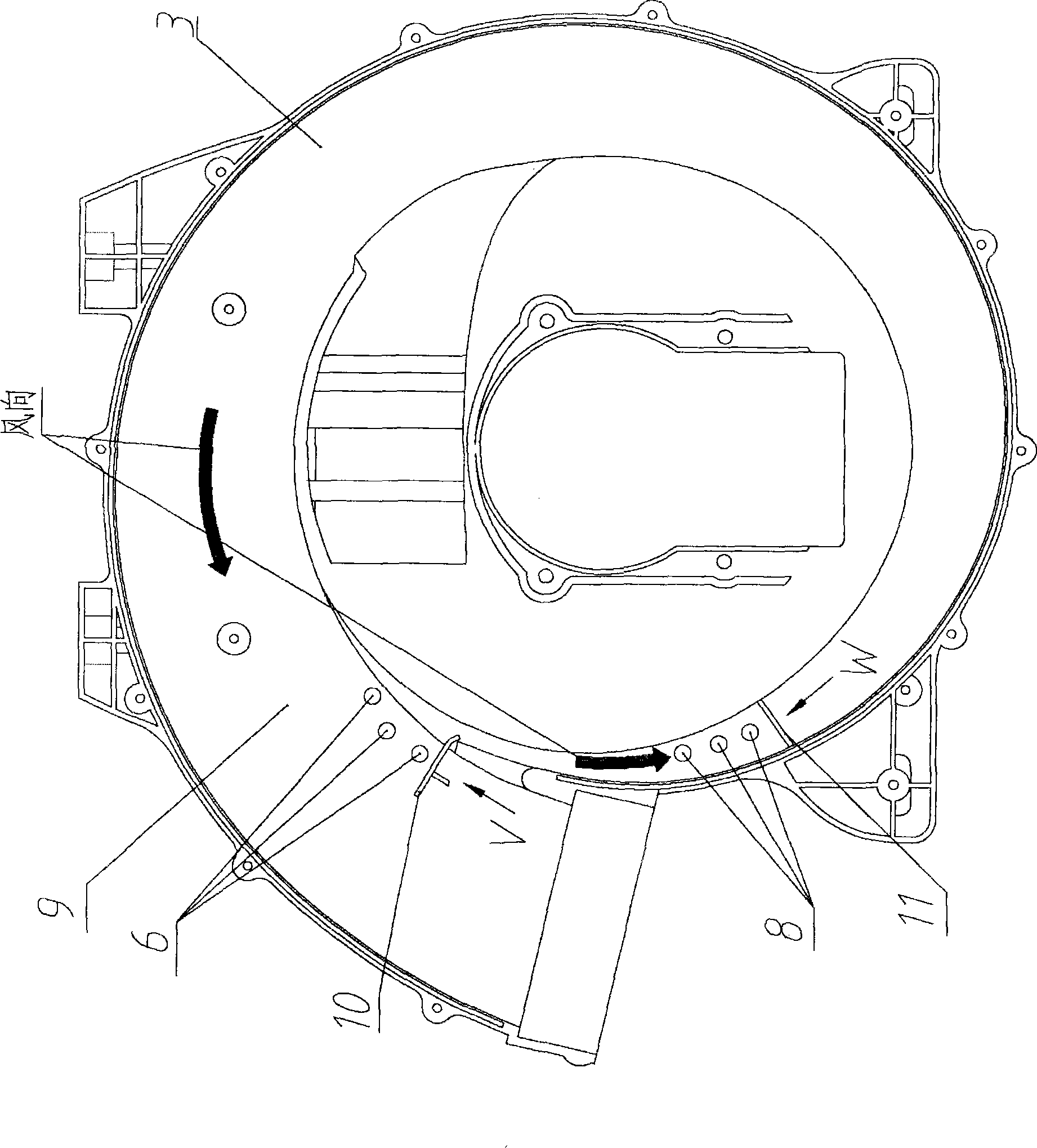

[0016] Such as figure 1 , figure 2 , image 3 , Figure 4 , attached Figure 5 Shown, the present invention scheme is by engine 1 (muffler 7), front half blower fan volute 3 (upper draft hole 6, lower draft vent 8, volute 9, upper windshield 10, lower windshield 11), The second half fan volute 5 and impeller 2 are formed.

[0017] The impeller 2 is placed in the volute 9 formed by the combination of the front half fan volute 3 and the back half fan volute 5, the front half fan volute 3 and the back half fan volute 5 are connected by fastening screws 4, and the impeller 2 is connected with the engine 1.

[0018] The upper air-introduction hole 6, the lower air-introduction hole 8, the upper windshield 10, and the lower windshield 11 are all on the front half fan volute 3, and the upper air-induction hole 6 and the lower air-induction hole 8 are multiple. The air hole 6 is positioned at the position close to the upper half of the muffler 7 on the front half fan volute 3 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com