Cement concrete expansion joint structure with large area ground, and implementation method thereof

A technology of cement concrete and expansion joints, which is applied in the direction of building structure, pavement details, and building material processing, etc. It can solve the problems that two adjacent plates cannot be disconnected, the temperature effect is easy to cause damage, and the cement concrete floor is damaged. Achieve the effects of reducing the risk of extrusion damage, convenient operation, and reducing the number of sealing packing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

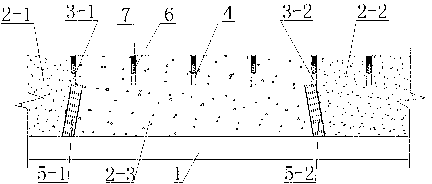

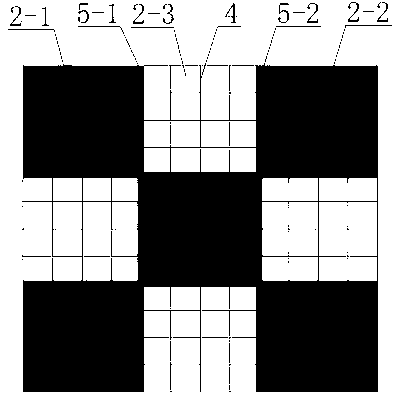

[0026] Such as figure 1 and figure 2 As shown, a large-area cement concrete expansion joint structure includes a cushion layer 1, concrete plates 2-1, 2-2, 2-3, main expansion joints 3-1, 3-2 and secondary expansion joints 4, There are main expansion joints 3-1, 3-2 between concrete plates 2-1, 2-2, 2-3, secondary expansion joints 4 are set on concrete plates 2-3, concrete plates 2-3 and secondary expansion joints 4 Form a "comb-shaped" cross-section, the main expansion joints 3-1, 3-2 are filled with extruded boards 5-1, 5-2, flexible packing 6 and flexible sealing material 7, and the secondary expansion joints 4 are filled with flexible Packing 6 and flexible sealing material 7. The distance between the main expansion joints 3-1 and 3-2 is 15m-25m, and the distance between the secondary expansion joints 4 is 3.5m-4.5m. The thickness of the concrete slabs 2-1, 2-2 and 2-3 is 150-300mm. The gap width of the upper 1 / 3 plate thickness range of the main expansion joints 3-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com