Mortar dry powder for building and plastering

A mortar dry powder and masonry technology, which is applied in the field of mortar dry powder, can solve problems such as hidden dangers of mortar quality, increased layering, and poor workability, and achieve the effects of good bonding strength, saving construction costs, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

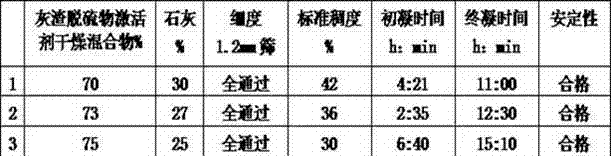

Embodiment 1

[0016] Embodiment 1, dry mortar powder for masonry plastering, which is prepared from fly ash slag, calcareous desulfurization product gypsum, lime and activator as raw materials. The specific preparation steps are:

[0017] 1) Mix calcareous desulfurization product gypsum with water at a weight ratio of 1:2, heat, impregnate and stir until boiling for 10 minutes, then filter, and use the filtrate and filter residue separately;

[0018] 2) Crush the fly ash with a particle size greater than 1mm, and use a 1mm mesh sieve instead of crushing the fly ash with a particle size not greater than 1mm;

[0019] 3) The sieved fly ash slag and calcareous desulfurization product hot-boiling impregnated filtrate are mixed according to the weight ratio of 2:1;

[0020] 4) The sieved fly ash residue and calcareous desulfurization product hot-boiling impregnated filter residue are mixed in a weight ratio of 1:1;

[0021] 5) Preparation of activator: Take 1 weight part of stearic acid and ...

Embodiment 2

[0028] Embodiment 2, dry mortar powder for masonry plastering, which is prepared from fly ash slag, calcareous desulfurization product gypsum, lime and activator as raw materials. The specific preparation steps are:

[0029] 1) Mix calcareous desulfurization product gypsum with water at a weight ratio of 1:2.5, heat, impregnate and stir until boiling for 20 minutes, then filter, and use the filtrate and filter residue separately;

[0030] 2) Crush the fly ash with a particle size greater than 1mm, and use a 1mm mesh sieve instead of crushing the fly ash with a particle size not greater than 1mm;

[0031] 3) The sieved fly ash and calcareous desulfurization product hot-boiling impregnated filtrate are mixed according to the weight ratio of 2.5:1;

[0032] 4) The sieved fly ash residue and calcareous desulfurization product hot-boiling impregnated filter residue are mixed in a weight ratio of 1:1;

[0033] 5) Preparation of activator: Take 1 weight part of stearic acid and a...

Embodiment 3

[0038] Embodiment 3, dry mortar powder for masonry plastering, which is prepared from fly ash slag, calcareous desulfurization product gypsum, lime and activator as raw materials. The specific preparation steps are:

[0039] 1) Mix calcareous desulfurization product gypsum with water at a weight ratio of 1:3, heat, impregnate and stir until boiling for 30 minutes, then filter, and use the filtrate and filter residue separately;

[0040] 2) Crush the fly ash with a particle size greater than 1mm, and use a 1mm mesh sieve instead of crushing the fly ash with a particle size not greater than 1mm;

[0041] 3) The sieved fly ash slag and calcareous desulfurization product hot-boiling impregnated filtrate are mixed according to the weight ratio of 3:1;

[0042] 4) The sieved fly ash residue and calcareous desulfurization product hot-boiling impregnated filter residue are mixed in a weight ratio of 1:1;

[0043] 5) Preparation of activator: Take 1 weight part of stearic acid and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com