Household steamed bread kneading and forming machine

A technology of a molding machine and a molding mechanism, which is applied in the directions of home appliances, applications, kitchen utensils, etc., can solve the problems of inconvenience, low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

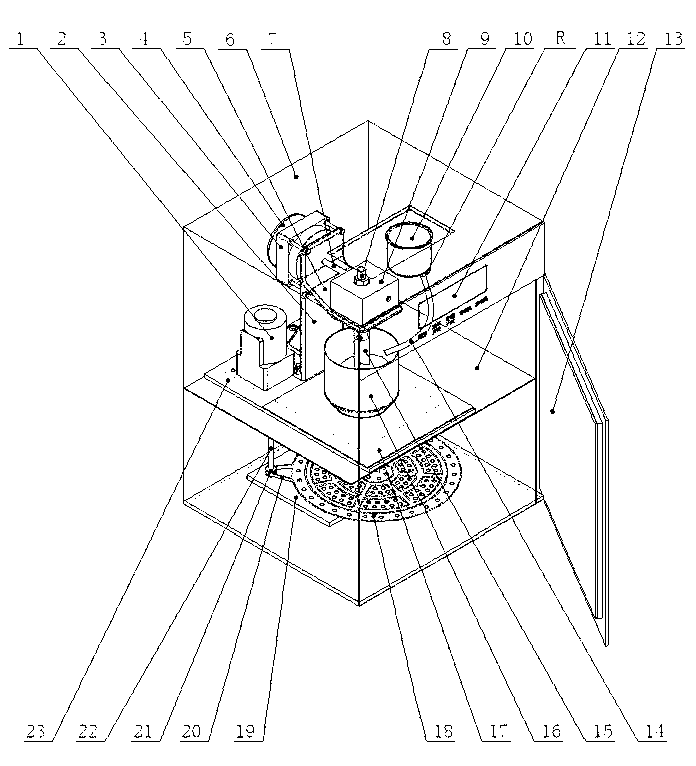

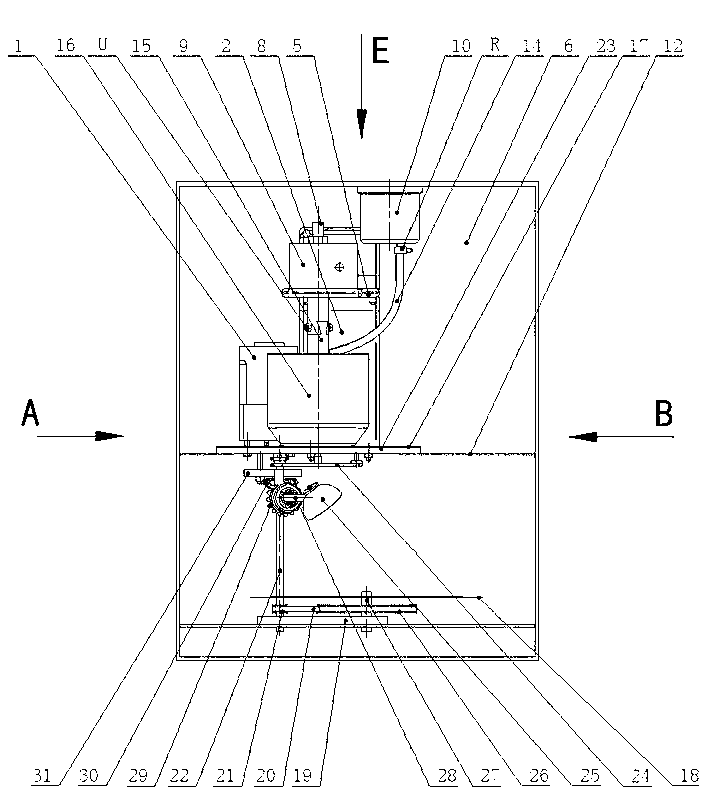

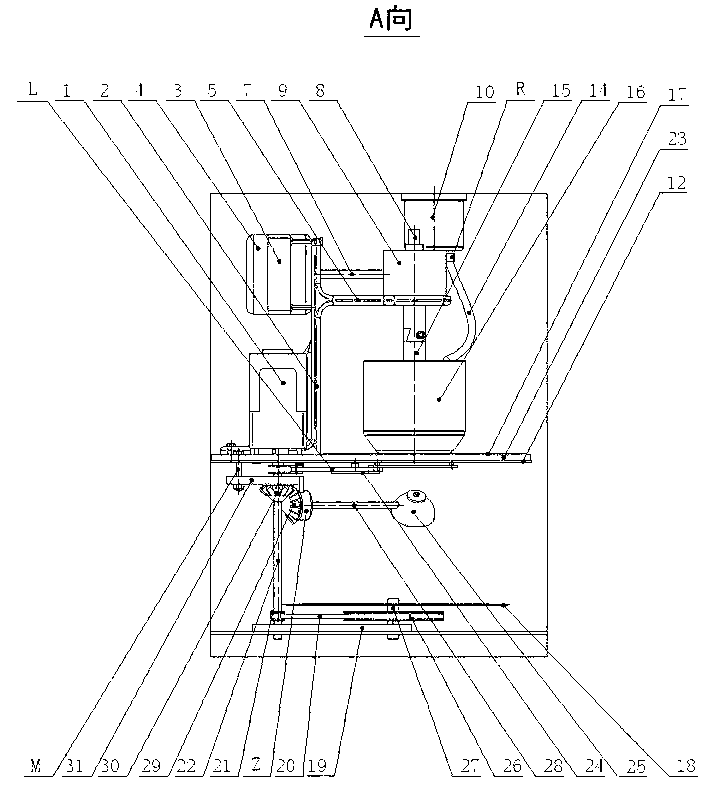

[0022] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6, the front opening of the casing 6 is provided with a machine door 13, and the upper side of the inner middle layer partition 12 is provided with a face-cut orifice plate 23, and the motor stand 2 and the stand support plate J are installed on the rear portion of the cut-face orifice plate 23, and the motor stand 2 is vertical Erection, the surface motor 4 is horizontally fixed on the back of the motor stand 2 top by the motor positioning frame 3 and the bolt M. The front of the motor stand 2 is connected to the reducer support plate 5, and the reducer 9 is vertically arranged. The output shaft 7 of the kneading motor 4 passes through the motor stand 2 and the reducer support plate 5 to connect to the reducer 9, the reducer shaft 8 passes through the reducer support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com