Adhesive sheet

A technology for bonding sheets and sheets, applied in the direction of adhesives, adhesive products, film/sheet adhesives, etc., to achieve the effects of good air leakage, stable opening degree and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

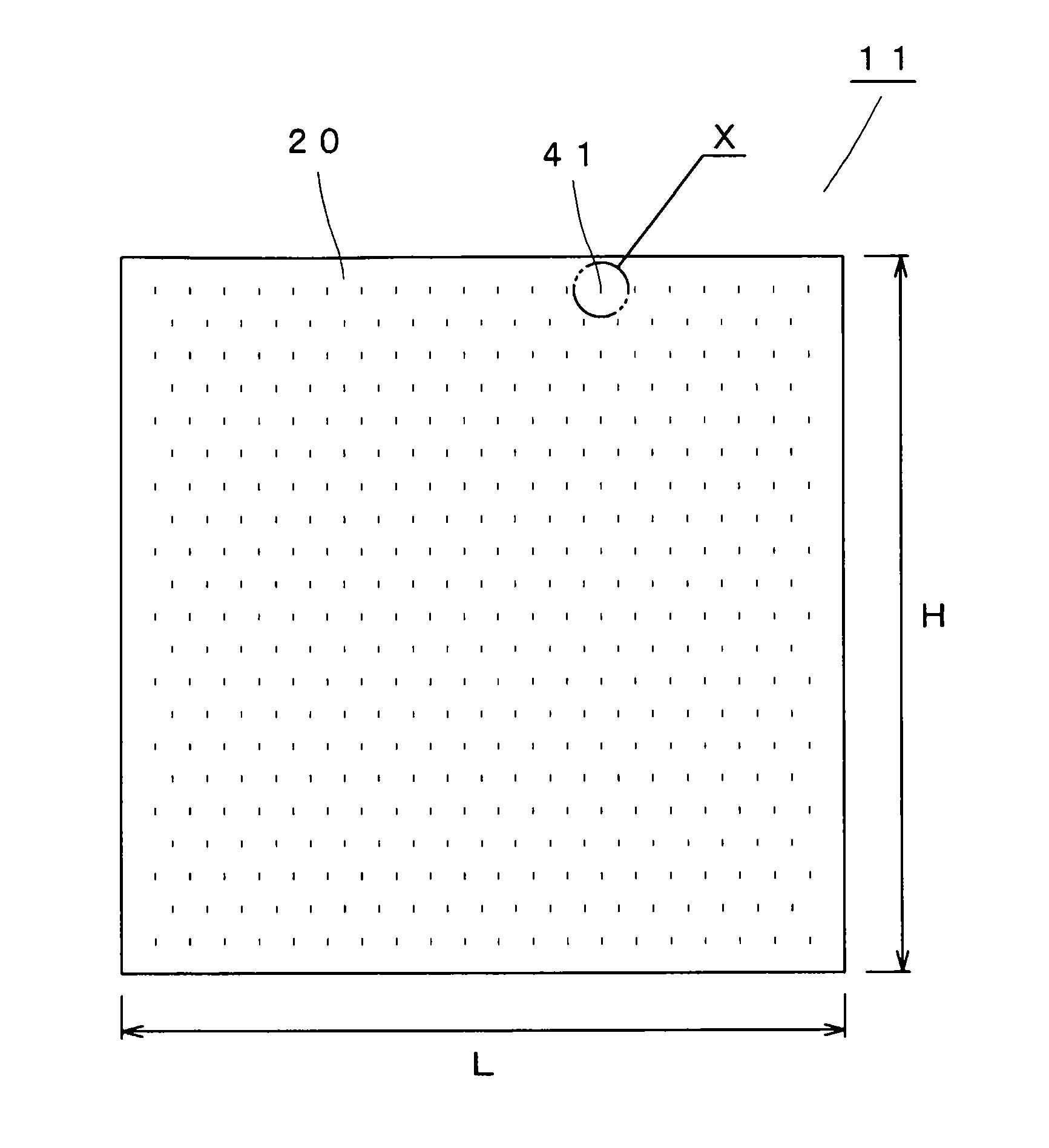

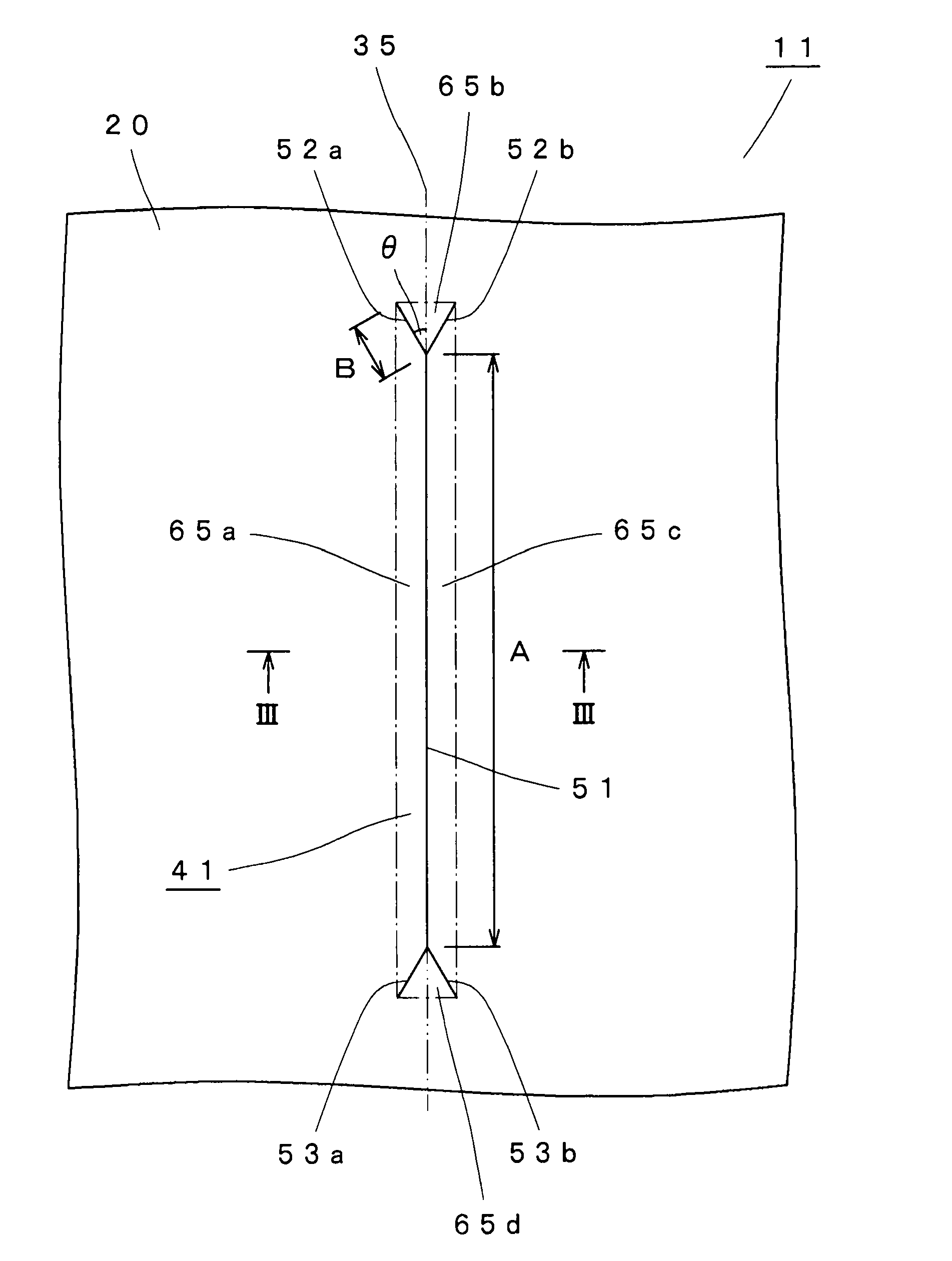

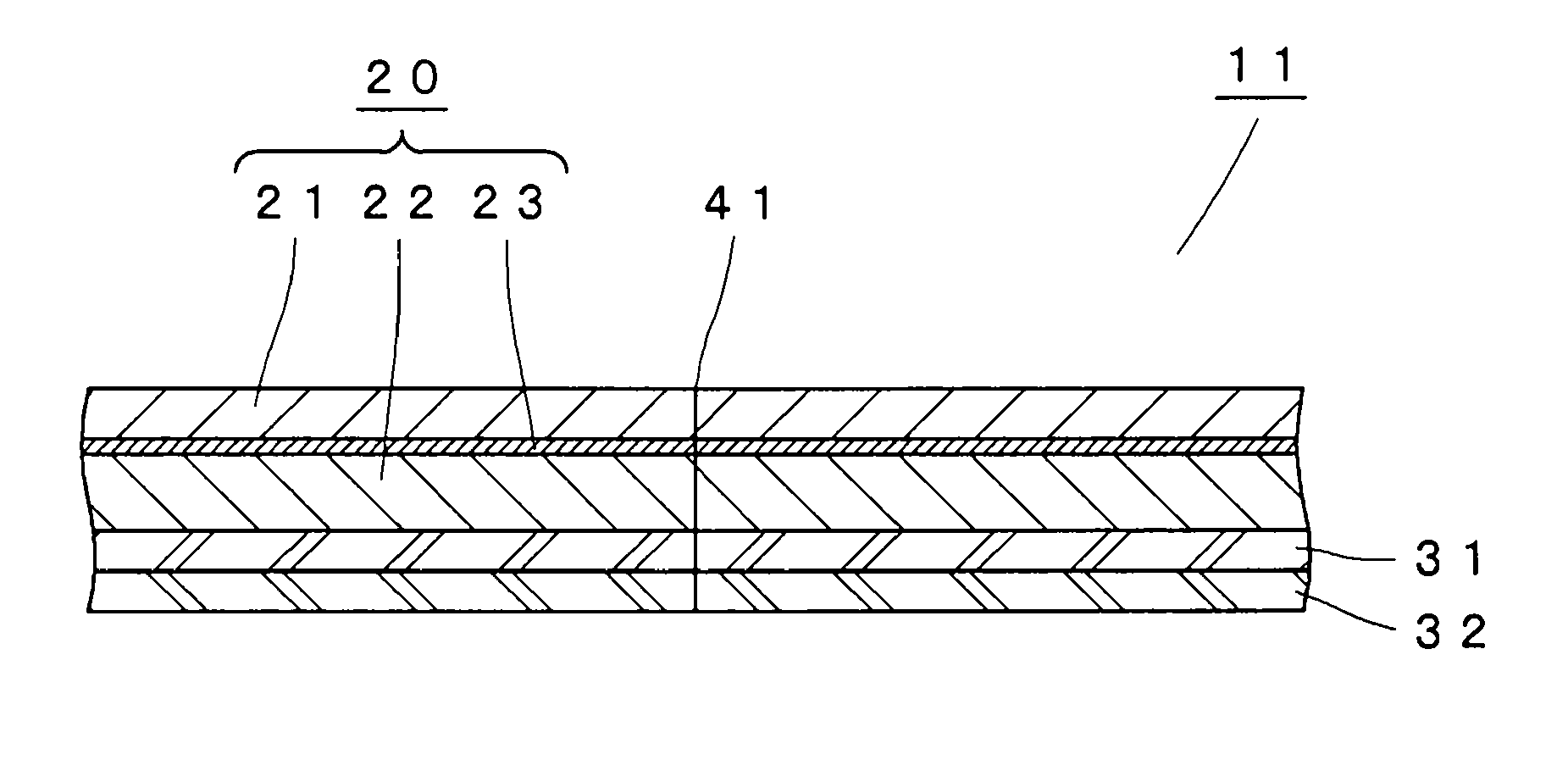

[0124] Embodiment 1 is the same as the light-shielding sheet based on the first embodiment, as figure 2 As shown, the length A of the first straight portion 51 of the slit 41 is set to 1.0mm, and the length B of each of the second straight portions 52a, 52b and each of the third straight portions 53a, 53b is set to 1.0 mm. Set to 0.1mm. In addition, the angle θ formed by each of the second linear portions 52a, 52b and each of the third linear portions 53a, 53b with the virtual straight line 35 is set to 30°. Furthermore, the density of the slits 41 is set to 400 places / 100cm 2 .

Embodiment 2

[0125] Example 2 is an example in which the angle θ of the slit is changed to 60° from the structure of the first example.

Embodiment 3

[0126] Example 3 is an example in which the angle θ of the slit is changed to 150° from the structure of Example 2, that is, it is the same as Figure 5 The slit 42 is shown in the same embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com