Anaerobic treatment method

一种处理方法、厌氧性的技术,应用在甲烷发酵处理的厌氧性处理领域,能够解决无法发挥稳定性能、颗粒缓慢解体、颗粒流出等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3、 comparative example 1

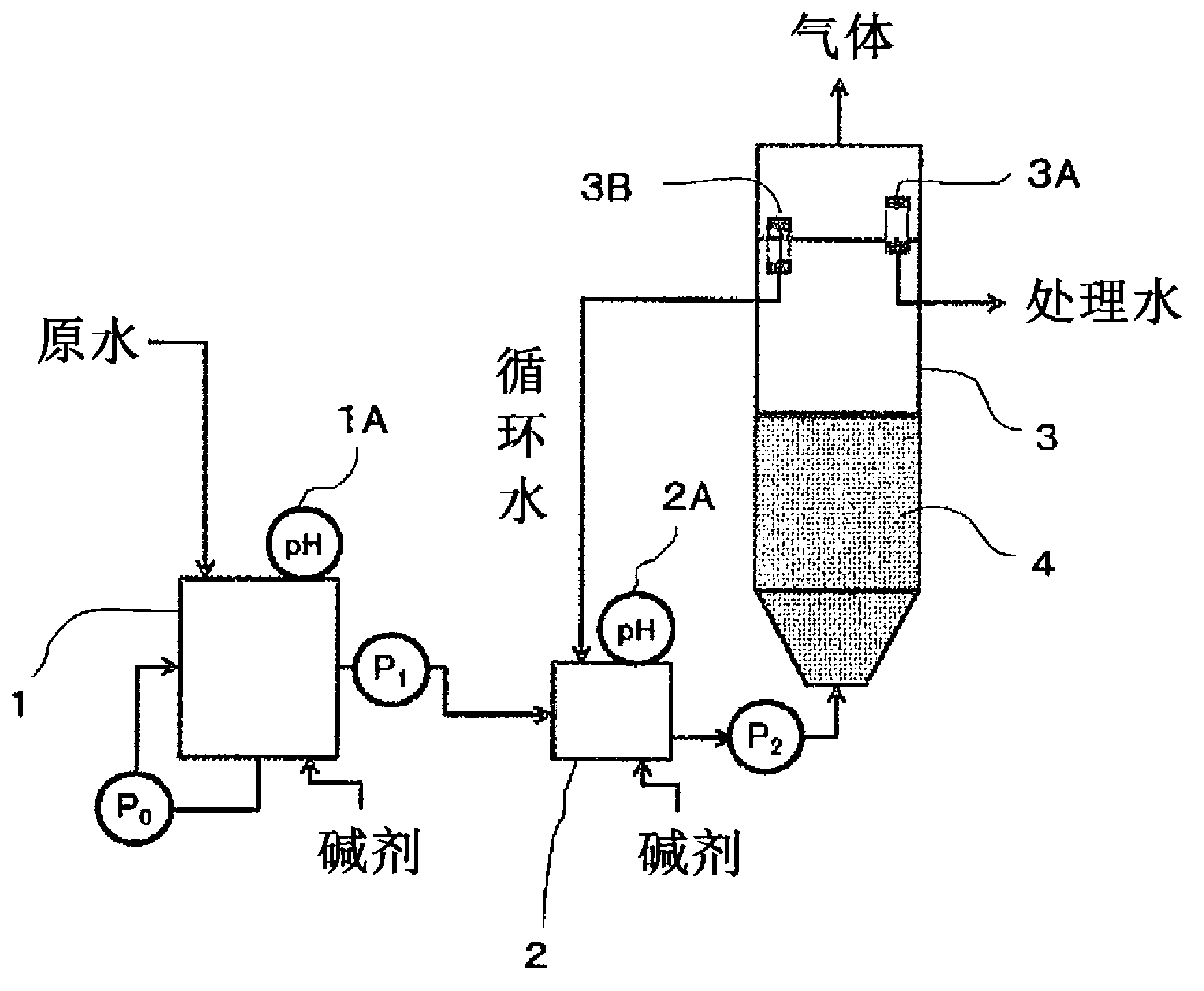

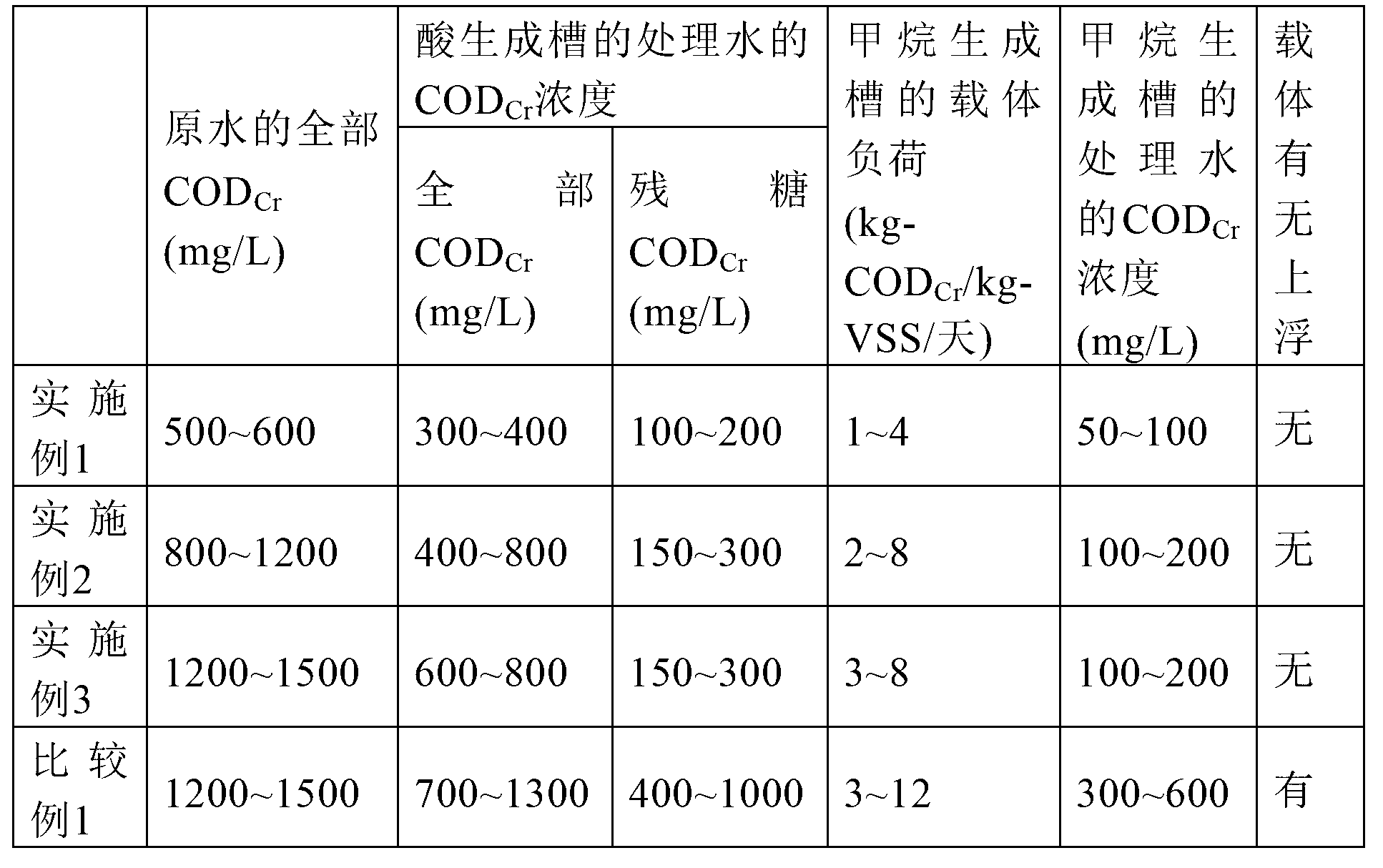

[0104] according to figure 1 The anaerobic treatment device shown, the synthetic drainage (COD) with sugar and protein as the main body Cr Concentration: 500~1500mg / L, all COD Cr COD derived from polymer components other than organic acids Cr Ratio: about 60%, pH 7.0) was used as raw water for water flow test.

[0105] In this anaerobic treatment device, after treating the raw water with the acid generating tank 1, the pump P 1 Supply to pH adjustment tank 2 and adjust pH with pump P 2 The pH-adjusted water is passed through the methanogenesis tank 3 filled with the fluid non-biological carrier 4 so as to flow upward, and the treatment is performed. A part of the effluent water from the methane generation tank 3 is circulated to the pH adjustment tank 2 as circulating water, and the rest is discharged out of the system as treated water. The water in the acid generation tank 1 uses the pump P 0 to loop. In the acid generation tank 1 and the pH adjustment tank 2, sodium h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt Flow Rate | aaaaa | aaaaa |

| Melt Flow Rate | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com