Novel spiral bushing and reverser thereof

A commutator and screw technology, applied in the field of a new type of spiral bushing and its commutator, can solve the problems that the processing performance needs to be improved, the commutator is easy to move, and the performance of the commutator is affected, so as to prevent the axial and Radial movement, good processing performance, and cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

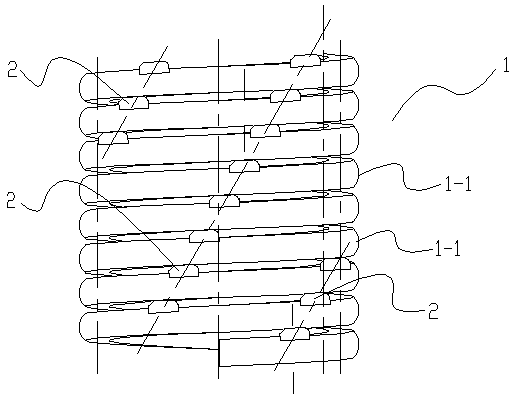

[0024] Embodiment: the novel spiral bushing of this embodiment is as figure 1 , 2 As shown in , 3, it includes a helical bushing body 1 formed by a plurality of helical coils 1-1. A plurality of bosses 2 forming gaps between adjacent helical turns 1-1.

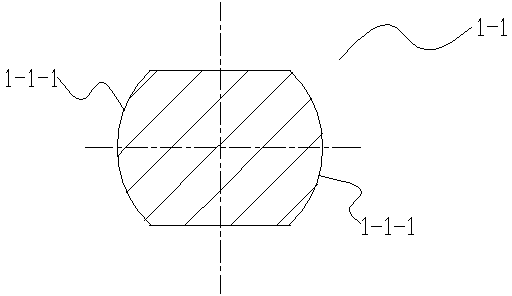

[0025] The spiral coil 1-1 is made of cold-rolled steel wire. The cross-section of the cold-rolled steel wire includes two convex arc-shaped sides 1-1-1, that is, the side of the cold-rolled steel wire is a convex arc surface, and the cold-rolled steel wire The steel wire also includes a planar upper end surface and a lower end surface.

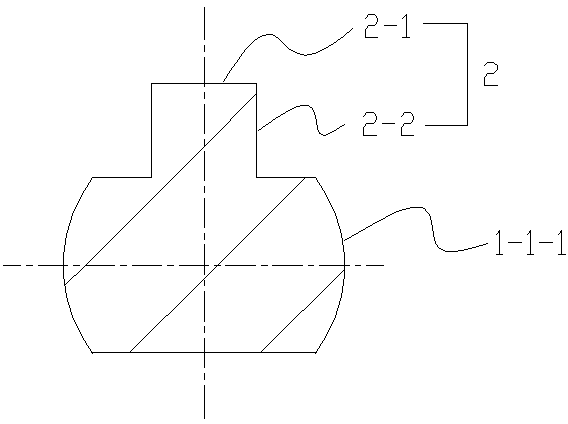

[0026] On the upper end surface of the cold-rolled steel wire, there are six equally divided bosses 2 radially pressed along the circumference of the spiral circle 1-1. The bosses 2 are longitudinally distributed at a certain angle on the spring circumference, and the bosses 2 include planar bosses. The upper end surface 2-1 and the two vertical side surfaces of the boss 2-2, the upper en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com