Yarn barrel locking device for aramid yarn of optical cable

A locking device and aramid yarn technology, applied in the direction of light guides, optics, optical components, etc., can solve the problems of inconsistent locking force of compression springs, large processing errors of inner diameter, and uneven installation of yarn bobbins, so as to avoid bending of optical cables and broken yarn and cable, prevent axial and radial movement, and ensure the effect of production stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

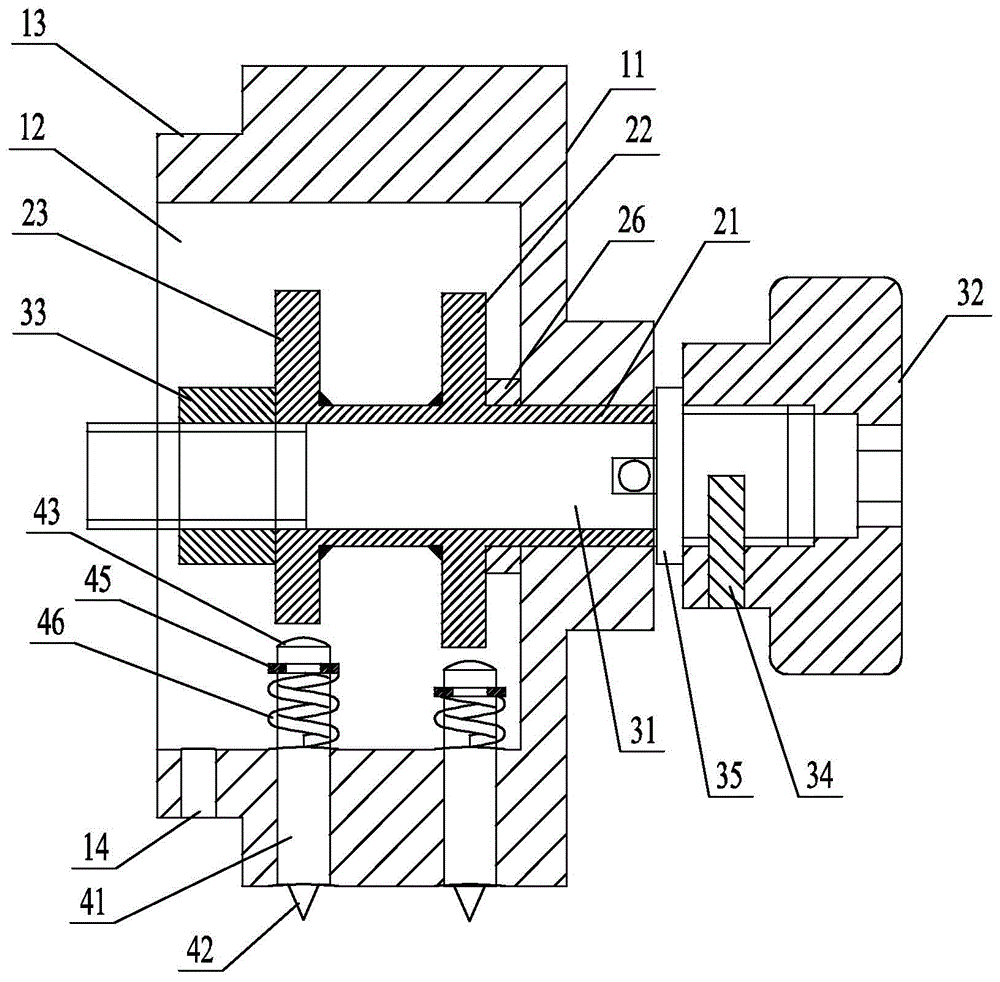

[0031] Such as figure 1 and Figure 7 As shown, the bobbin locking device for optical cable aramid yarn of the present invention includes a cylindrical cam seat 11, the front end of which is recessed inwardly with a cavity 12, and the cavity 12 is a cylindrical cavity coaxial with the cam seat 11. . The side wall of the front end of the cam seat 11 has an annular neck 13 , and the side wall of the neck 13 has a threaded hole 14 .

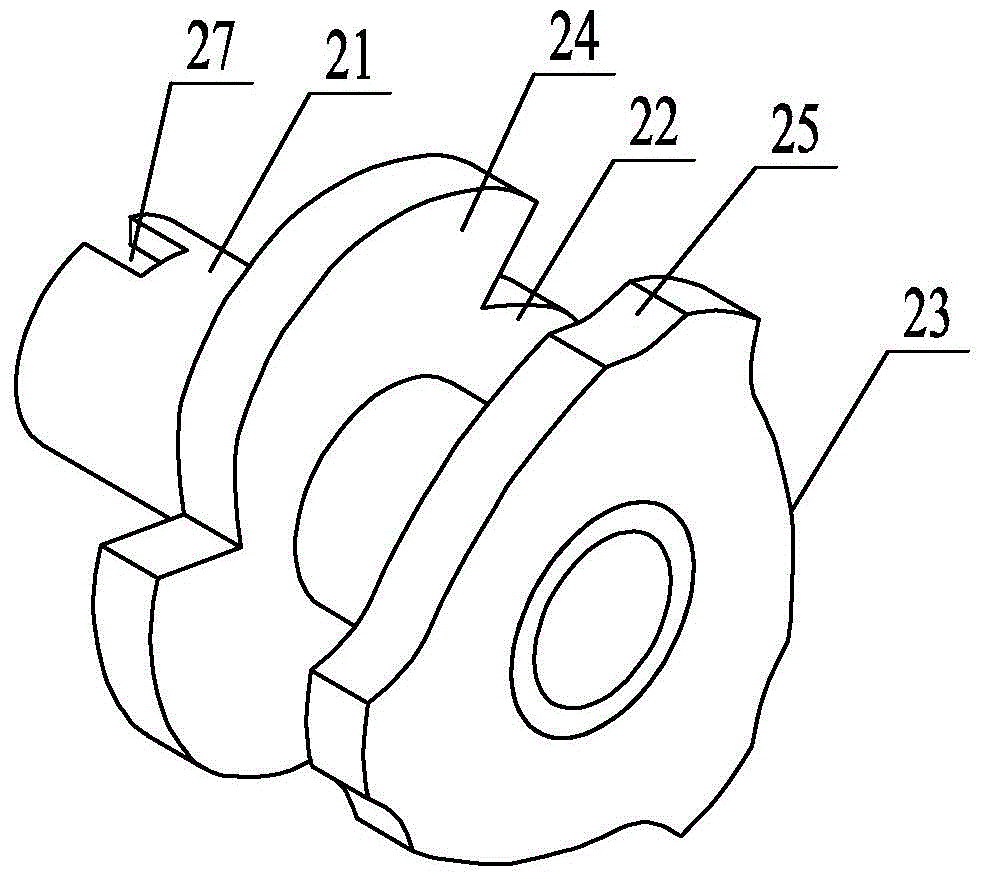

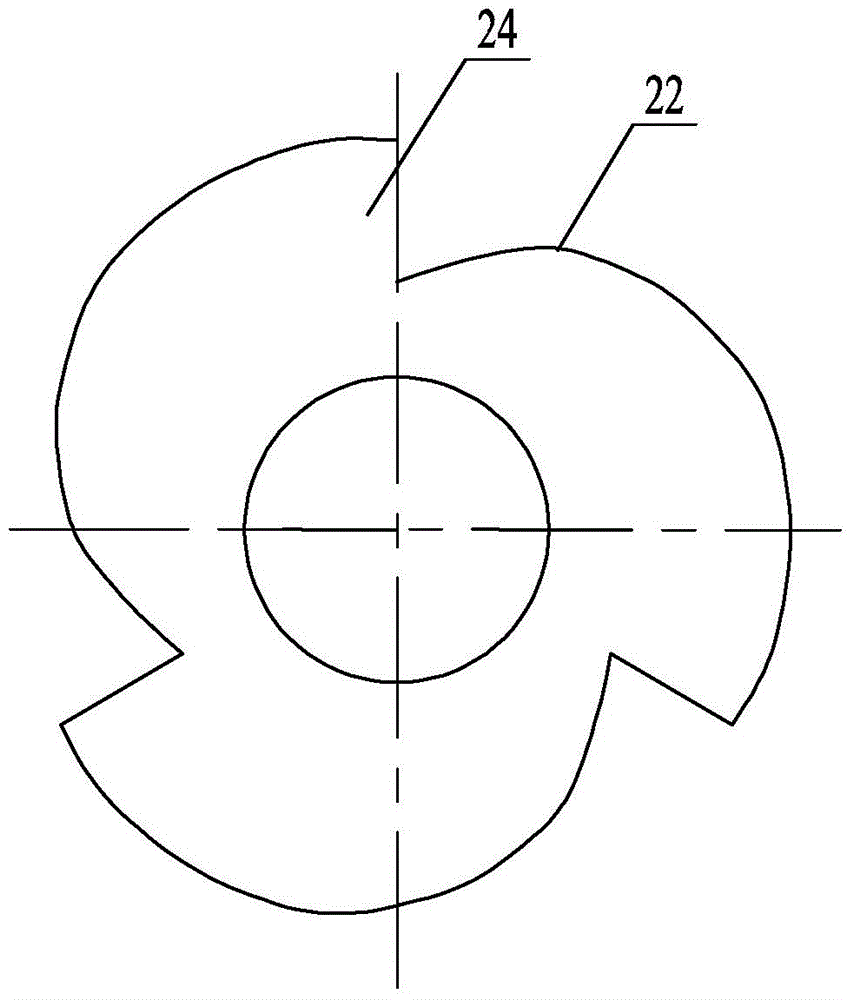

[0032] Such as figure 1 As shown, a hollow shaft 21 is arranged axially in the cavity 12, and a first cam 22 and a second cam 23 are sheathed on the outside of the hollow shaft 21, and the first cam 22 is located behind the second cam 23. end, in the present embodiment, the two cams are fixed to the hollow shaft 21 by welding. The side wall of the cam base 11 is provided with at least one pair of through holes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com