Die-casting die for auto spare parts

A technology for die-casting molds and auto parts, applied in the field of die-casting molds for auto parts, can solve the problems of single die-casting mold design, inability to fix the lower template, limited application scope, etc., achieve precise positioning, prevent aging, and improve deformation stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The standard parts used in the present invention can be purchased from the market, and the special-shaped parts can be customized according to the instructions and the accompanying drawings. The specific connection methods of each part adopt mature bolts, rivets, welding in the prior art , pasting and other conventional means, no longer described in detail here.

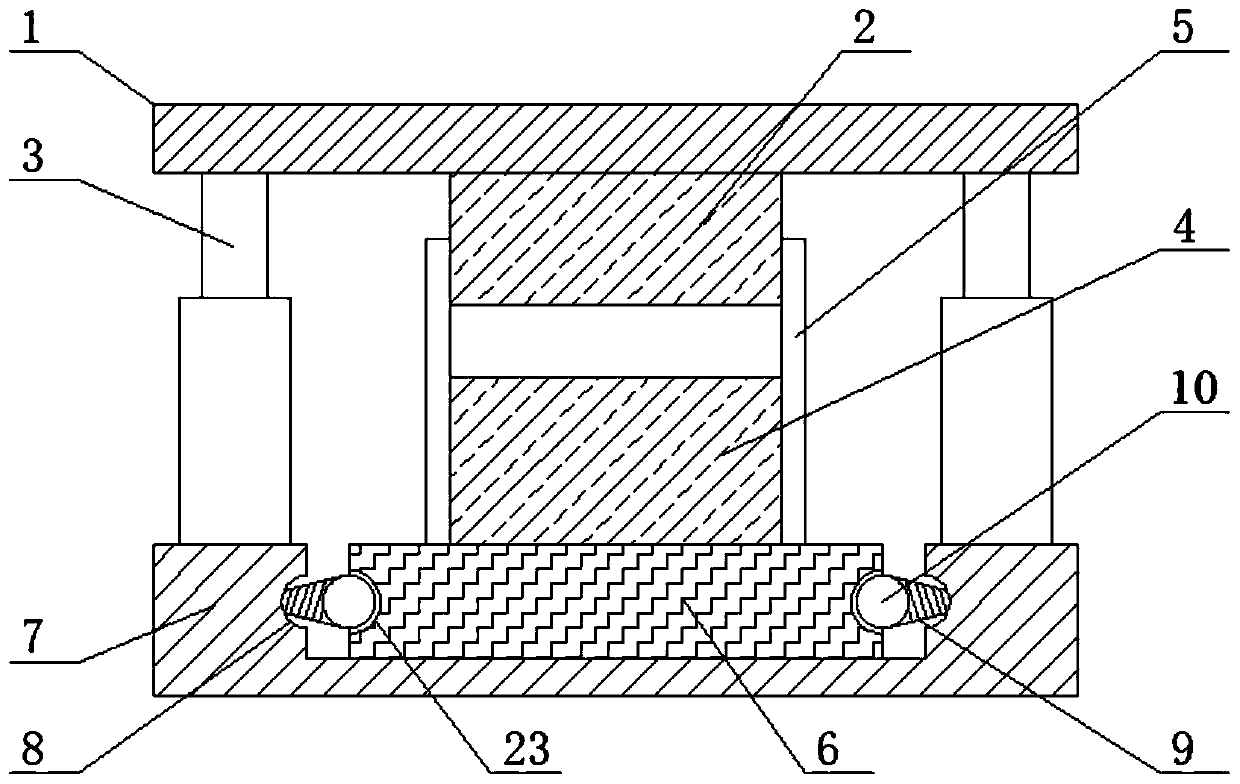

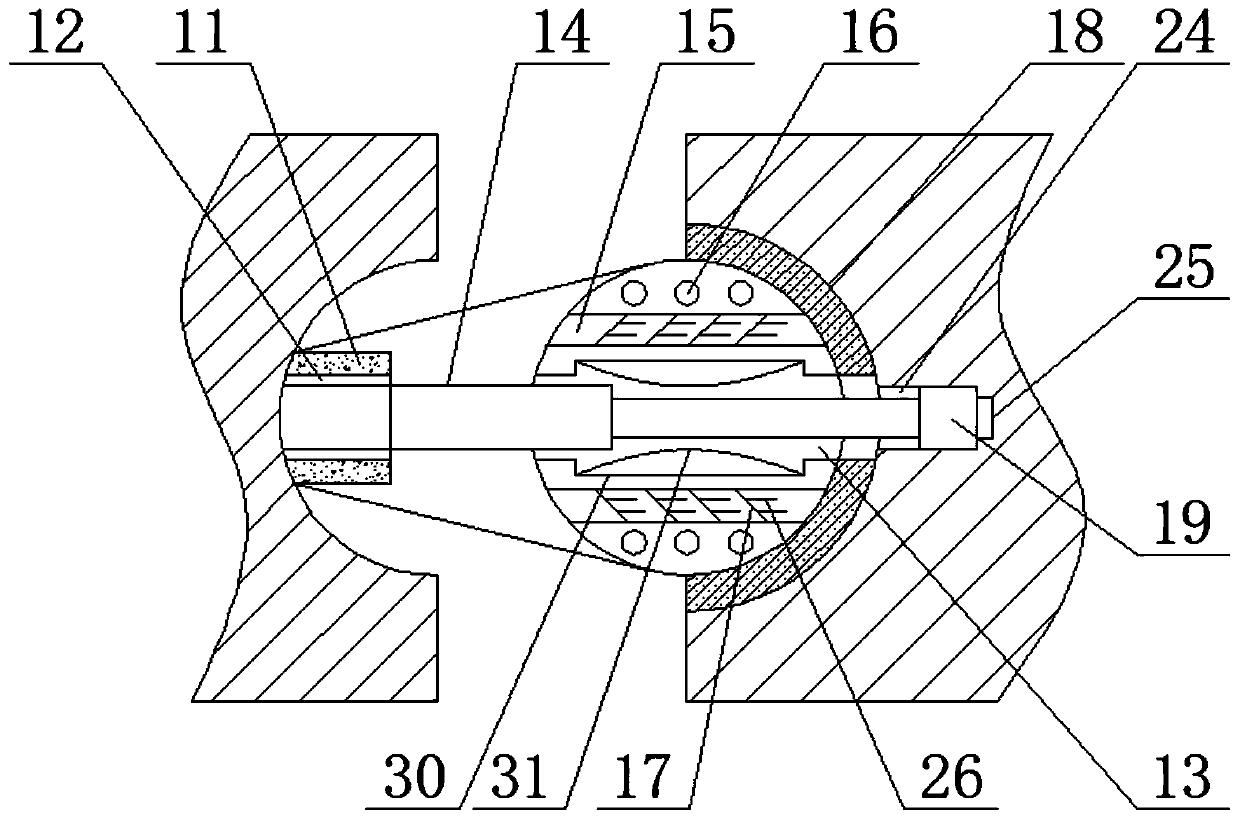

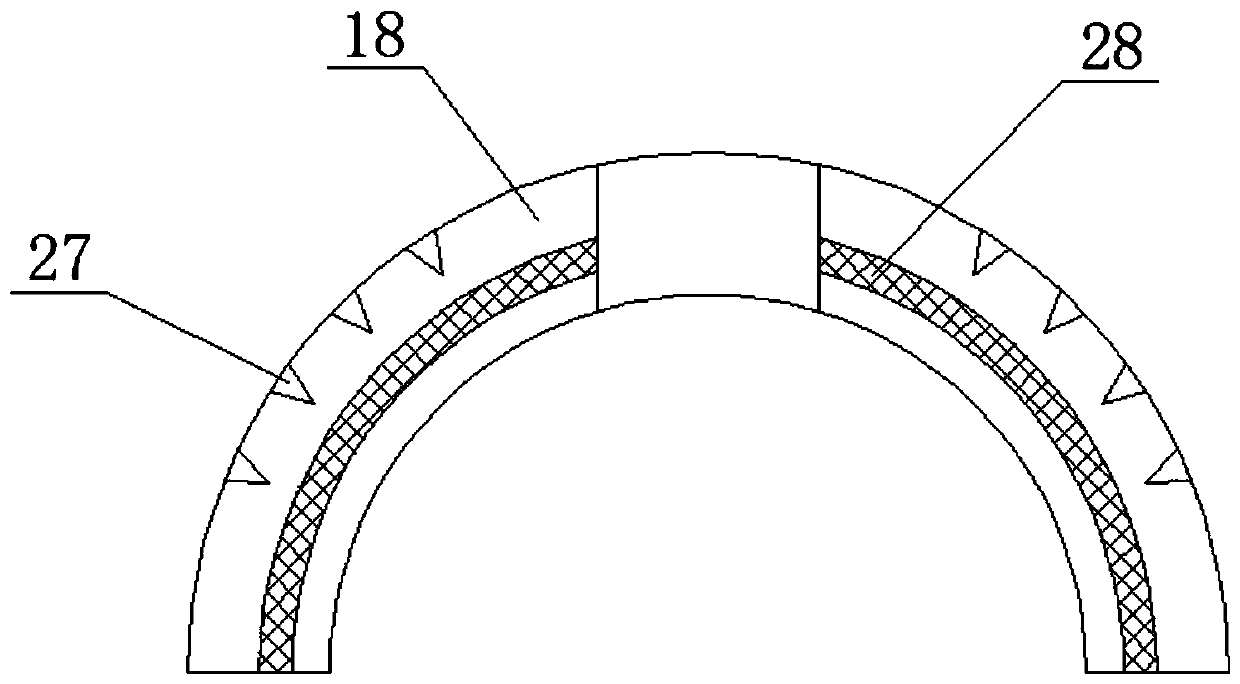

[0022] refer to Figure 1-8A specific embodiment of the present invention includes an upper formwork 1, the bottom surface of the upper formwork 1 is fixedly connected with an upper platen 2 and a vertically arranged first telescopic rod 3, the lower platen 4 is located directly below the upper platen 2 and is connected to the side formwork 5, The side mold 5 is fixedly connected with the lower formwork 6, and the first telescopic rod 3 is fixedly connected with the base 7. The inner side wall of the base 7 has some first semicircular grooves 8, and the bottom surface of the first semicircular groove 8 is in c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com