Gradient band gap nano-silicon thin film and graded band gap nano-silicon thin film solar cell

A nano-silicon thin film and solar cell technology, which is applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of low open-circuit voltage and fill factor, large light-induced attenuation, and low conversion efficiency of nano-silicon solar cells, so as to avoid interface problems. effect, increased short-circuit current, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

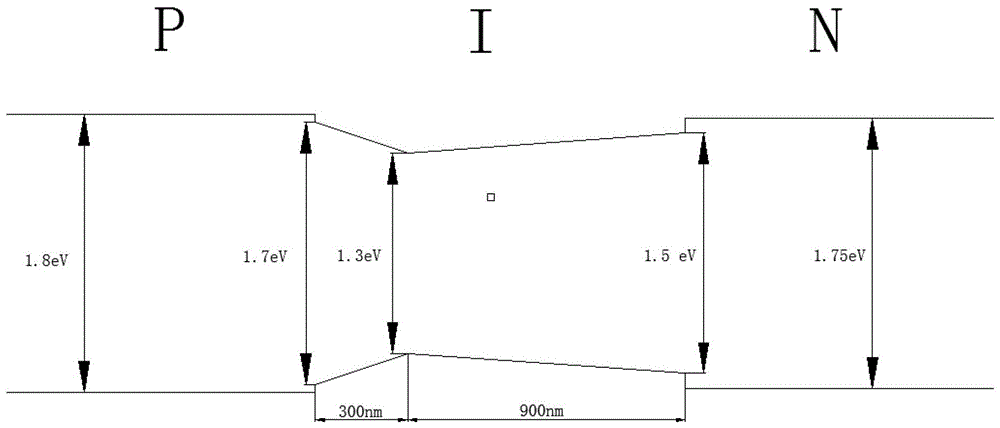

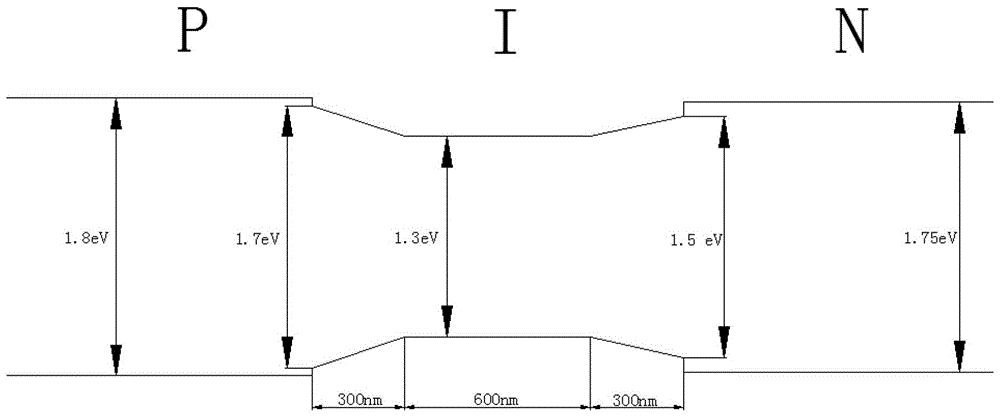

[0026] The graded bandgap nano-silicon thin film material in this specific embodiment is a mixed-phase material composed of amorphous silicon, crystal grains and grain boundaries. The band gap of the selected crystalline silicon is 1.12eV, and that of amorphous silicon is 1.75eV; the crystallization rate of nano-silicon thin film (the ratio of crystal phase to amorphous phase) ) ranges from 40% to 70%; by controlling the crystallization rate to change within the aforementioned range, the bandgap of the nano-silicon thin film with graded bandgap is 1.3eV~1.5eV. The method of controlling the crystallization rate includes adjusting the core preparation parameters of the nano-silicon thin film, such as the concentration of silane (SC), the level of the preparation power and the level of the preparation pressure, etc.

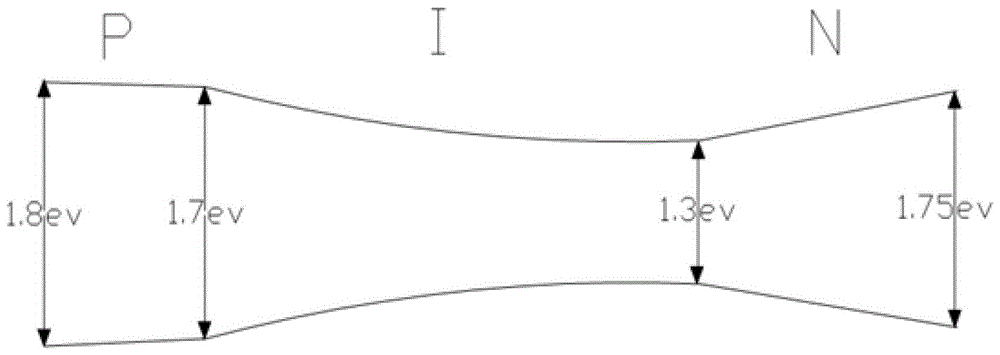

[0027] The graded bandgap has multiple structures, and the present invention proposes four schemes, the first such as figure 1 As shown in , a "C" type graded stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com