Powder mixture for dust cores

A powder magnetic core and mixed powder technology, which is applied in the direction of magnetic core/yoke, inductor/transformer/magnet manufacturing, magnetic materials, etc., can solve the problems of molded body expansion, magnetic property reduction, inductance reduction, etc., and achieve suppression of expansion , The effect of preventing density reduction and suppressing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

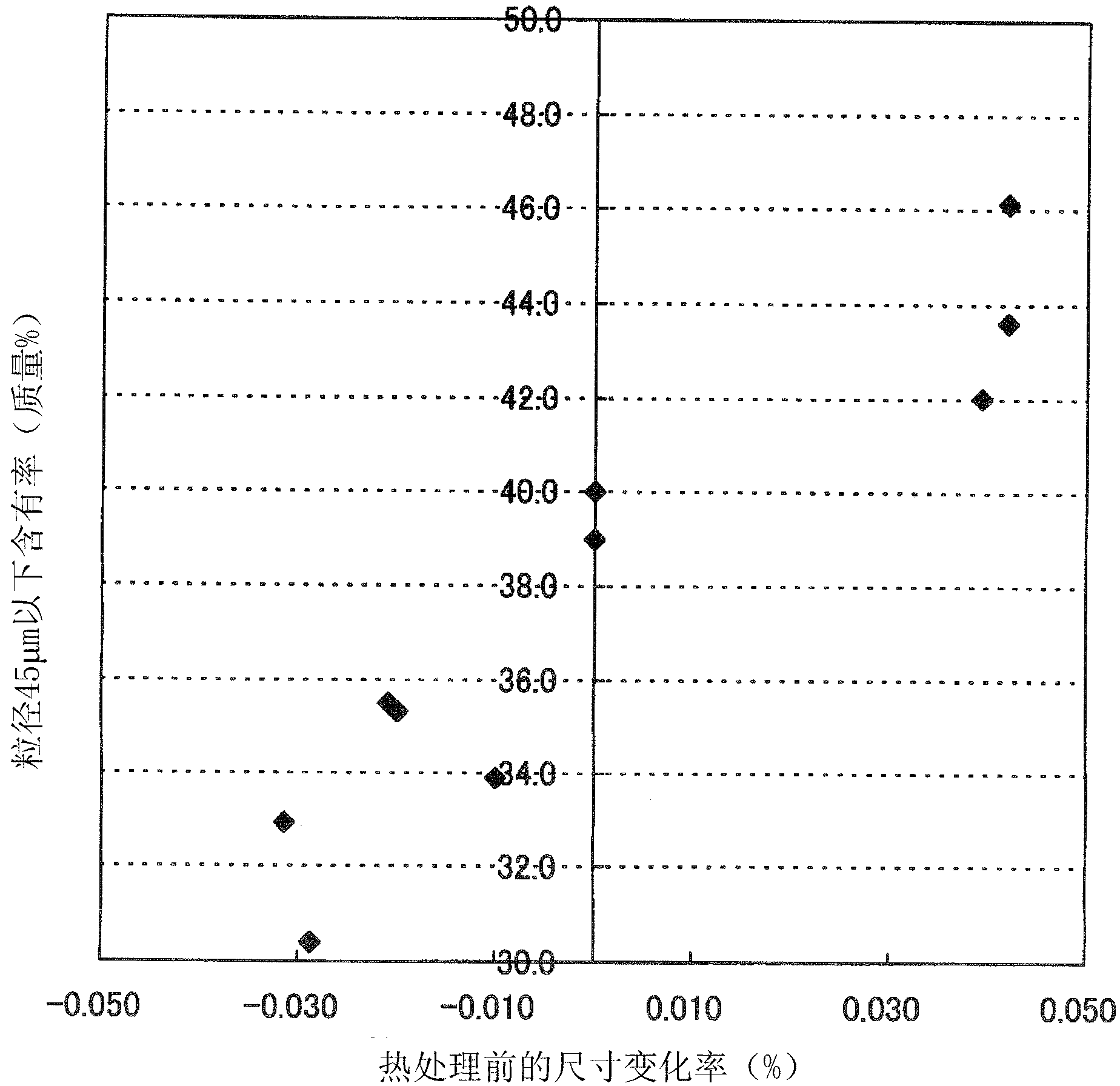

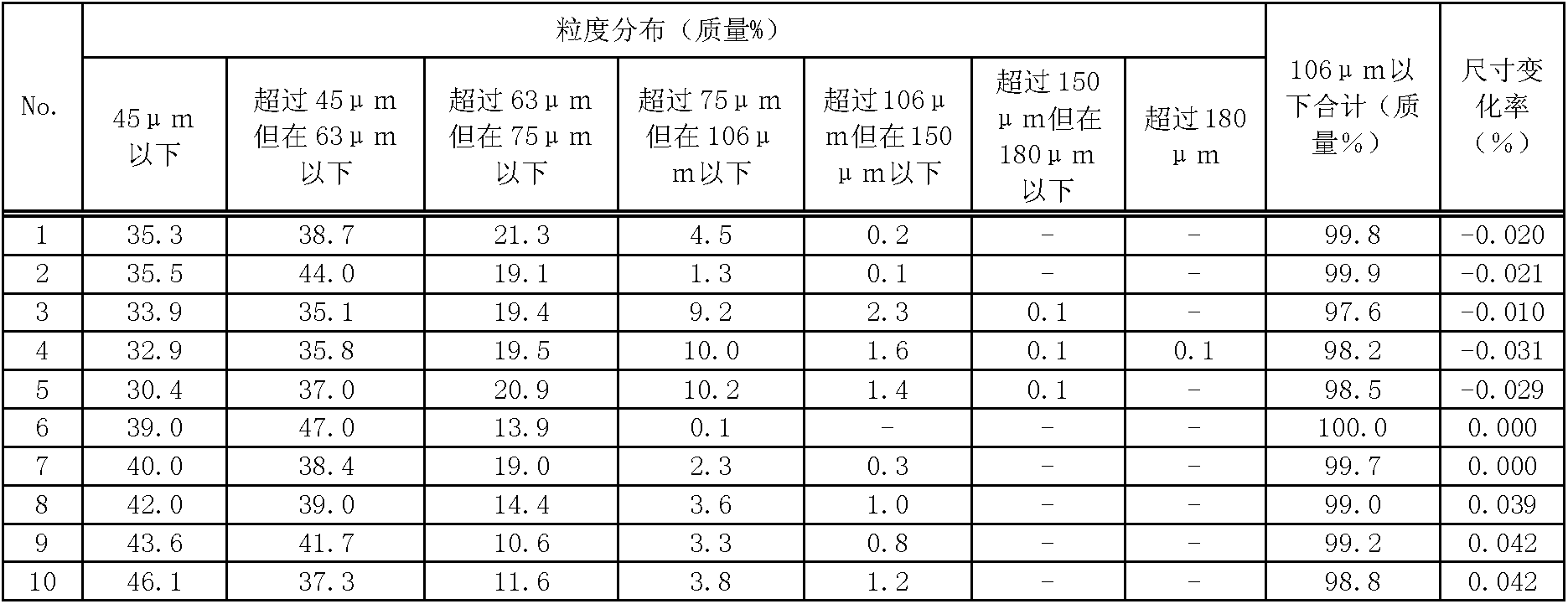

[0018] The present inventors, when heat-treating a molded body obtained by molding a mixed powder of soft magnetic iron-based powder and a lubricant coated with an insulating film, in order to suppress the expansion of the molded body, the dimensions of the molded body before and after the heat treatment were adjusted to The rate of change is less than 0.001% and has been studied repeatedly. As a result, they found that the rate of dimensional change of molded articles due to heat treatment can be reduced by appropriately adjusting the particle size distribution of the mixed powder, and completed the present invention. Hereinafter, the reason for accomplishing the present invention will be described.

[0019] Among the dust cores, for example, powder cores used for inductors, when the excitation frequency is high frequency, in order to reduce eddy current loss, soft cores with a small particle size (for example, particle size of 150 μm or less) are generally used. Magnetic ir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com