A system and method for monitoring the operation status of a group of cutter heads and disc-shaped hobs of a roadheader

A disc-shaped hob, operating state technology, applied in the testing of mechanical components, testing of machine/structural components, devices using electric/magnetic methods, etc., can solve problems such as reducing rock-breaking performance and improve operating efficiency , reduce construction risks, and improve operational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

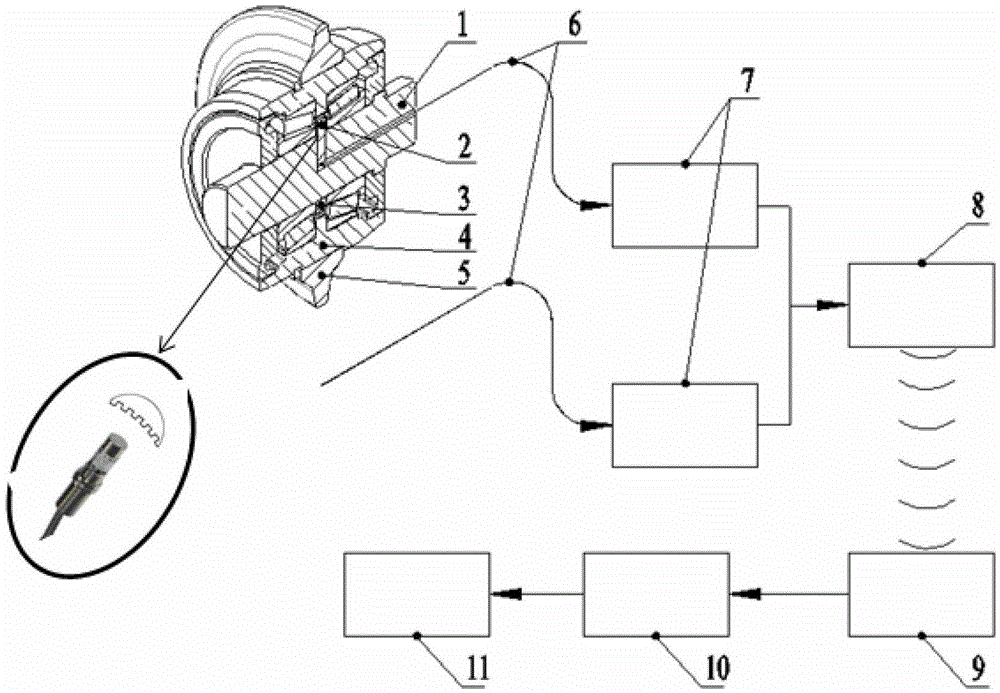

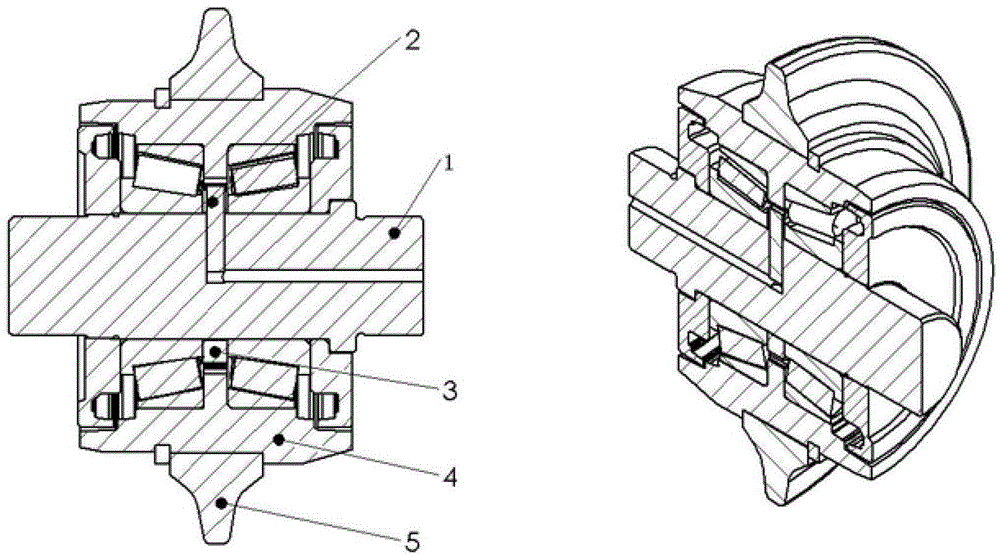

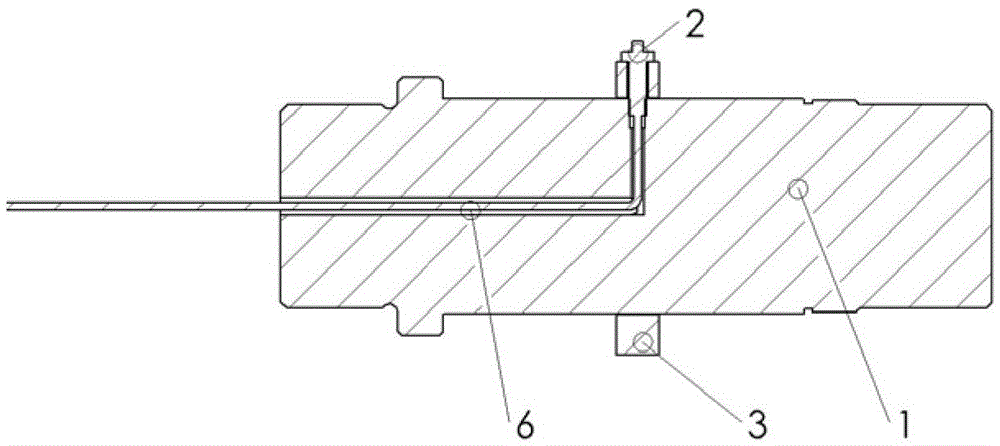

[0028] The present invention obtains the individual rotation speed of the disc-shaped hob by means of a sensor, stores the rotation speed signal and position signal of each individual in the tool group in the memory through a multi-channel signal integration device, and transmits the signal to the excavation through a wireless transmitter. machine control room. A wireless signal receiver is set in the control room of the roadheader, and the individual rotation speed signal of the disc hob represented by each signal (hereinafter referred to as "individual measured value") is stored in the computer, and compared with a pre-stored storage unit. compared to individual baseline values. The individual reference value is related to the installation position of the disc hob and the rotational speed of the disc hob.

[0029] According to the invention, an individual reference value is determined by comparing the individual measured values of the disc hob with individual reference va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com