A high-speed mud pulse generator

A technology of mud pulse and generator, which is applied in the field of high-speed mud pulse generator and mud pressure pulse generator, and can solve the problems of low reliability, weak pulse signal and low transmission rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

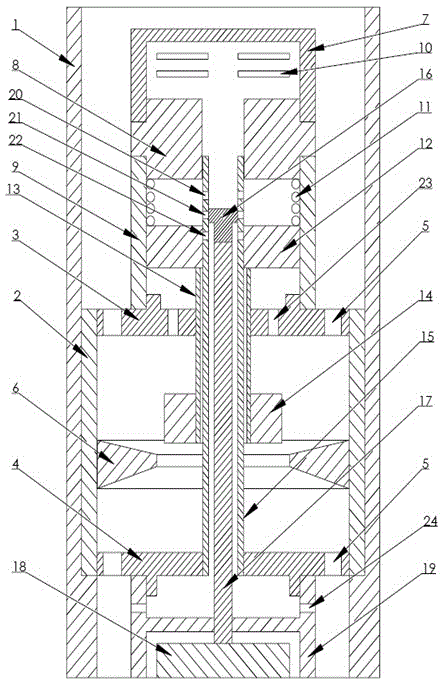

[0017] The technical scheme of a high-speed mud pulse generator is: the high-speed mud pulse generator consists of a flow tube assembly, a main valve assembly, a drive assembly, a through-shaft assembly and a hanging drill collar; the flow barrel assembly consists of a flow barrel, a throttle ring, an upper mounting plate, and a lower mounting plate; the main valve assembly consists of a mud filter, an upper joint of the piston chamber, 1 piston chamber, 1 force spring, 1 piston, 1 piston connecting rod, and 1 movable valve; the drive assembly consists of 1 driver and 1 driver chamber; the through shaft assembly consists of 1 control valve , 1 driving shaft and 1 through shaft. The flow tube assembly is installed inside the hanging drill collar, the main valve assembly is installed on the upper part of the flow tube assembly, the drive assembly is installed on the lower part of the flow tube assembly, and the through shaft assembly is located in the center of the device, conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com