Double-effect cementing prefluid with surfactant as suspending agent

A technology of surfactant and cementing prefluid, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve problems affecting compatibility and cementing sealing effect, and achieve good compatibility , Good ability to control water loss and improve hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

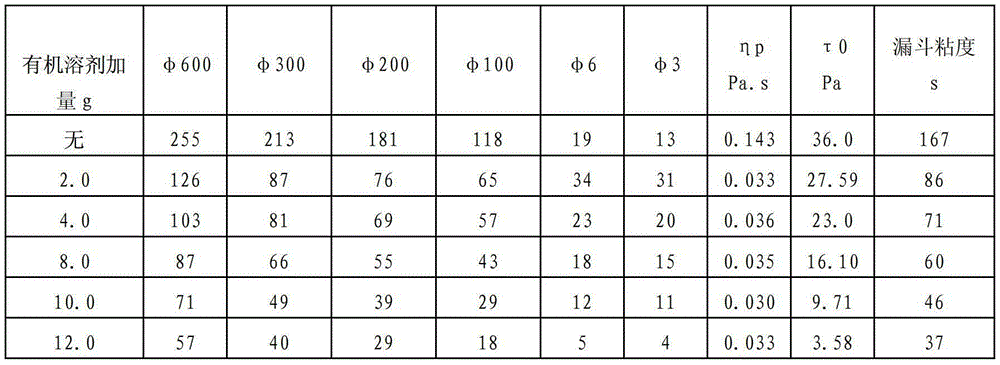

[0009] First prepare the flushing suspension: take 40g fatty alcohol polyoxyethylene ether sodium sulfate (AES), 50g fatty acid polyoxymethyl ester, 3g ethylene glycol ether, then add 7g ethylenediaminetetraacetic acid sodium (EDTA), and stir well . Then add 70 g of the prepared flushing suspension and 0.8 g of silicone oil defoamer to 400 g of water and stir for 30 min. According to density requirement 1.30g / cm 3 , add 202g of 200-mesh barite powder, stir evenly to obtain a double-effect pre-liquid.

Embodiment 2

[0011] Other conditions remain unchanged, according to the density requirement 1.1g / cm 3 Add 62g of 200 mesh barite.

Embodiment 3

[0013] Other conditions remain unchanged, according to the density requirement 1.5g / cm 3 Add 361g of 200 mesh barite.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com