A kind of method of synthesizing solution type neodymium phosphate complex

A complex and neodymium phosphate technology, which is applied in the field of compound synthesis, can solve the problems of a large amount of ethanol water waste liquid, the product is difficult to dissolve in alkane solvent, and the cumbersome drying process of neodymium phosphate, and achieves low production cost, simple production process, and maintains activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

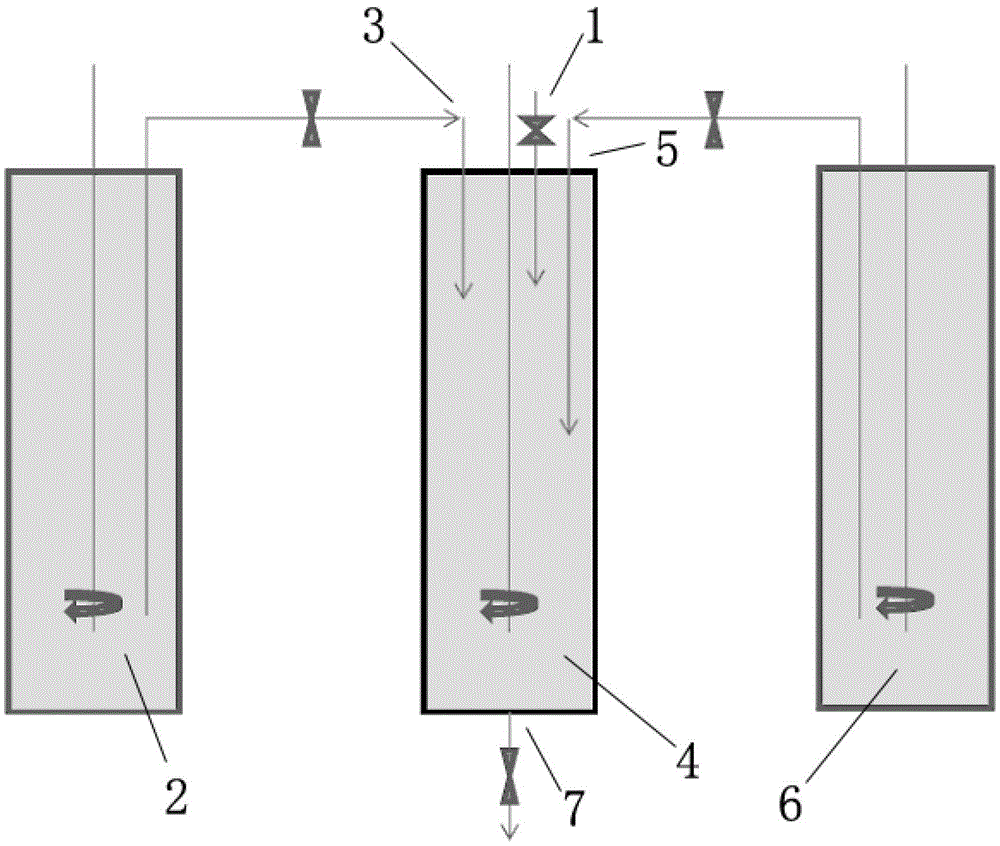

[0037] This embodiment provides a method for synthesizing solution-type neodymium phosphate complexes, which uses figure 1 The production device shown is carried out, and the method comprises the following steps:

[0038] 1, neodymium chloride hexahydrate is mixed with neodymium chloride aqueous solution in neodymium chloride solution still 2, and concentration is 1.31mol / L;

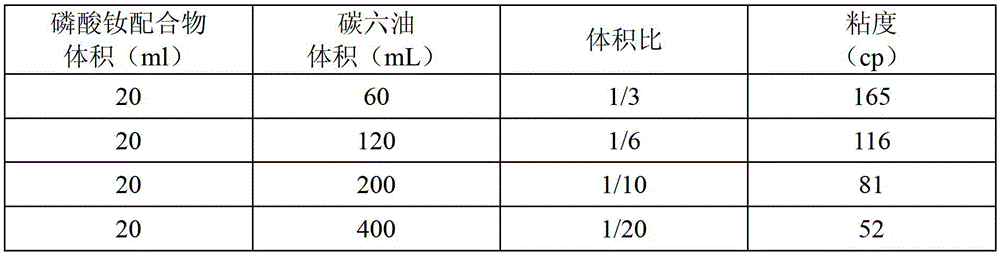

[0039] 2. Add 840 kg of C6 oil into the reactor 4 through the first feed port 1, then add 150 kg of 2-ethylhexyl phosphate, and stir for 5 minutes;

[0040] 3. Add 16kg of sodium hydroxide to 150kg of pure water to prepare an alkaline solution, and then add it to the reaction kettle 4 for reaction. The reaction temperature is controlled at 30-50°C, and the reaction time is controlled at 30 minutes;

[0041] 4. Add the neodymium chloride aqueous solution in the neodymium chloride solution kettle 2 to the reaction kettle 4 through the second feed port 3 for reaction, the addition amount of the neodymium c...

Embodiment 2

[0047] This embodiment provides a method for synthesizing solution-type neodymium phosphate complexes, which uses figure 1 The production device shown is carried out, and the method comprises the following steps:

[0048] 1, neodymium chloride hexahydrate is mixed with neodymium chloride aqueous solution in neodymium chloride solution still 2, and concentration is 1.31mol / L;

[0049] 2. Add 880 kg of C6 oil into the reactor 4 through the first feed port 1, then add 158 kg of bis(2-ethylhexyl) phosphate, and stir for 5 minutes;

[0050] 3. Add 16kg of sodium hydroxide to 150kg of pure water to prepare an alkaline solution, and then add it to the reactor 4 for reaction. The reaction temperature is controlled at 20-40°C, and the reaction time is controlled at 30 minutes;

[0051] 4. Add the neodymium chloride aqueous solution in the neodymium chloride solution kettle 2 into the reaction kettle 4 through the second feed port 3 to react, the addition amount of the neodymium chlori...

Embodiment 3

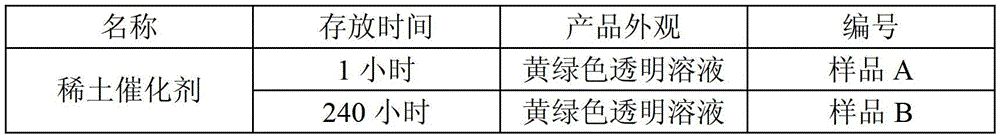

[0057] Using the solution-type neodymium phosphate complex prepared in Example 1 to mix and age with alkylaluminum hydrides and alkylaluminum chlorides, a rare earth catalyst that can be stored for a long time can be prepared for the polymerization of dienes such as butadiene and isoprene .

[0058] Catalyst: The catalyst is composed of solution-type neodymium phosphate complex, diisobutylaluminum hydride, and sesquiethylaluminum. The molar ratio of the three is: solution-type neodymium phosphate complex: diisobutylaluminum hydride: sesquiethylaluminum Aluminum base=1:10:3.5, wherein, the molar amount of the solution-type neodymium phosphate complex is calculated by neodymium, the molar amount of diisobutylaluminum hydride is calculated by aluminum, and the molar amount of sesquiethylaluminum is calculated by chlorine;

[0059] Preparation method: In the catalyst aging bottle under the protection of nitrogen, first add solution-type neodymium phosphate complex, then add diisob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com