Coiling iron core overturning and hoisting apparatus

A spreader and winding technology, which is applied in the field of winding iron core overturning spreader devices to achieve the effects of high lifting and overturning efficiency and fast lifting speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

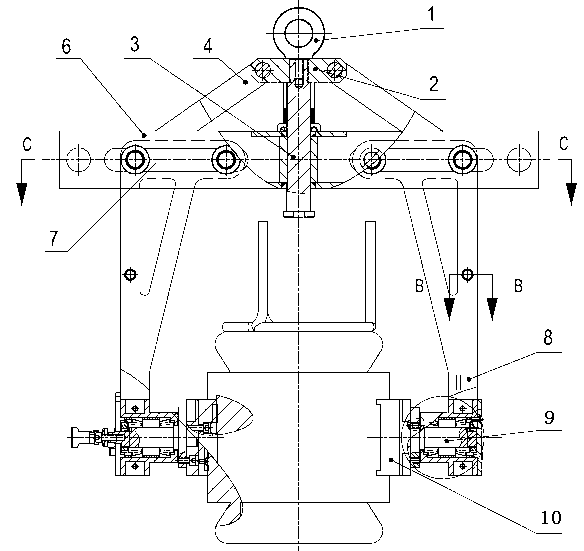

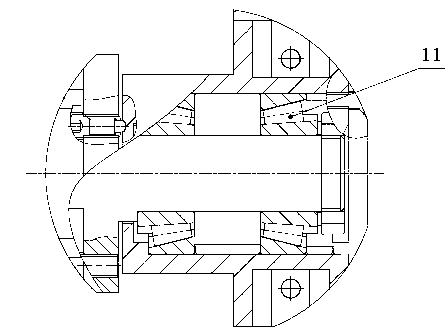

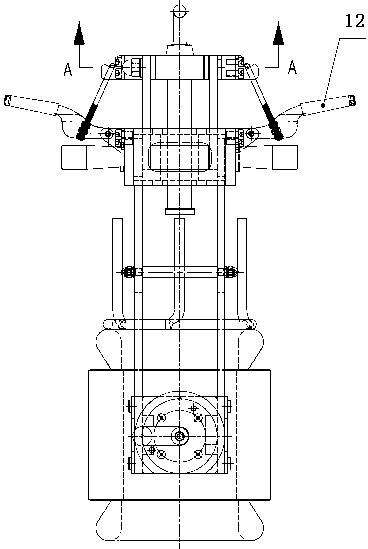

[0017] Figure 1-Figure 6 A structural schematic diagram of a winding iron core overturning sling device is shown. In the figure, it includes lifting lug 1, connecting body 2, boom 3, connecting rod 4, connecting rod bolt assembly 5, spreader main body 6, L-shaped bracket 8, rotary shaft 9, clamping block 10, ball plunger 11 , quick clamp 12, bracket bolt assembly 13, connecting shaft 14, handle 15, rotating arm 16, positioning plunger 17; lifting lug 1 is connected to connecting body 2, boom 3 passes through connecting body 2, connecting body 2 and four connecting rods 3 are connected by two rotating shafts 9. The connecting rods 4 are divided into two groups. connected, the two L-shaped brackets 8 form a group, and the bolt assembly is provided with two bearings, which are positioned in the chute 7 of the main body of the spreader th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com