Image forming apparatus

An image and equipment technology, applied in the field of image forming equipment, can solve problems such as jamming and sheet contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

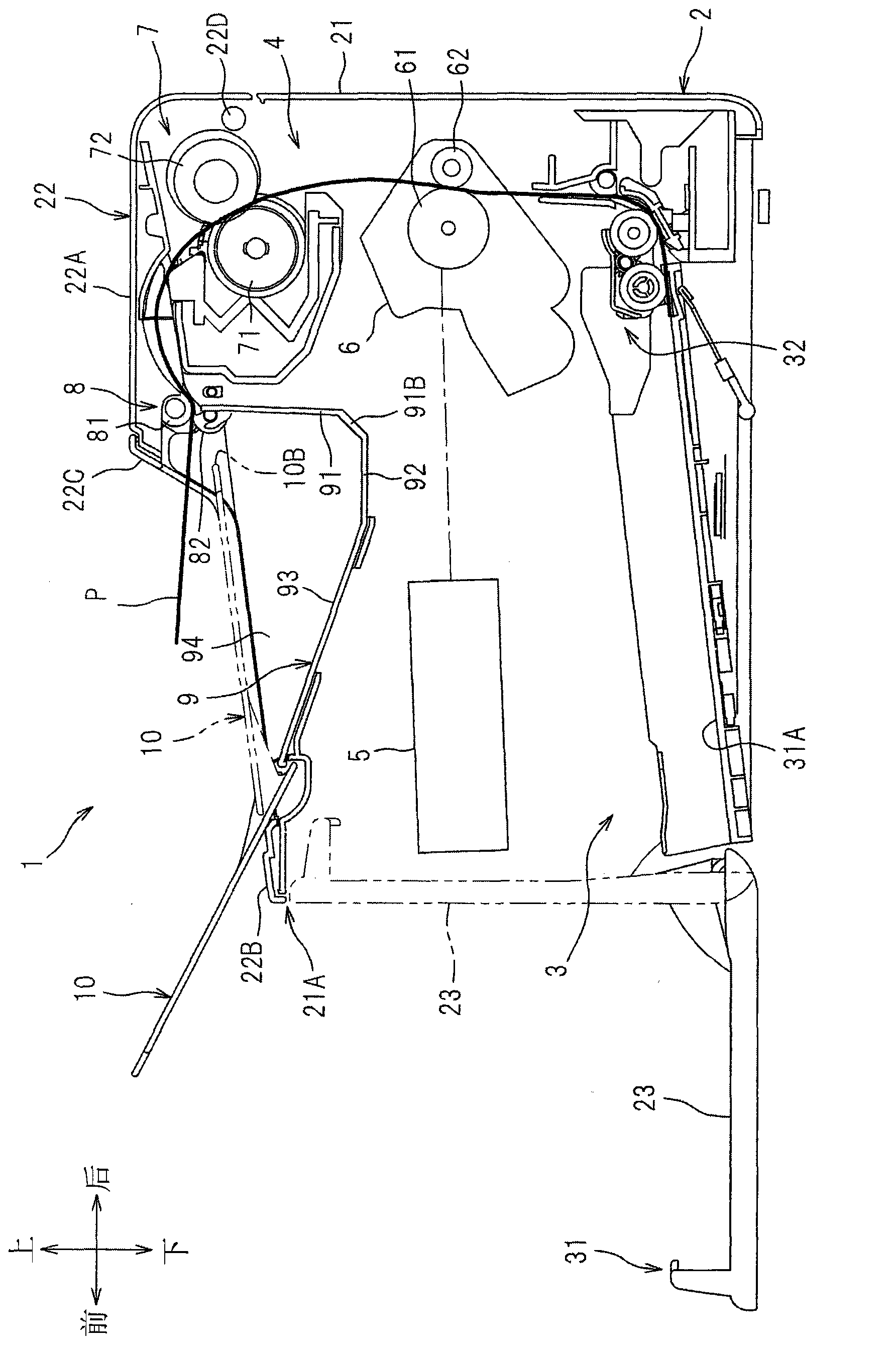

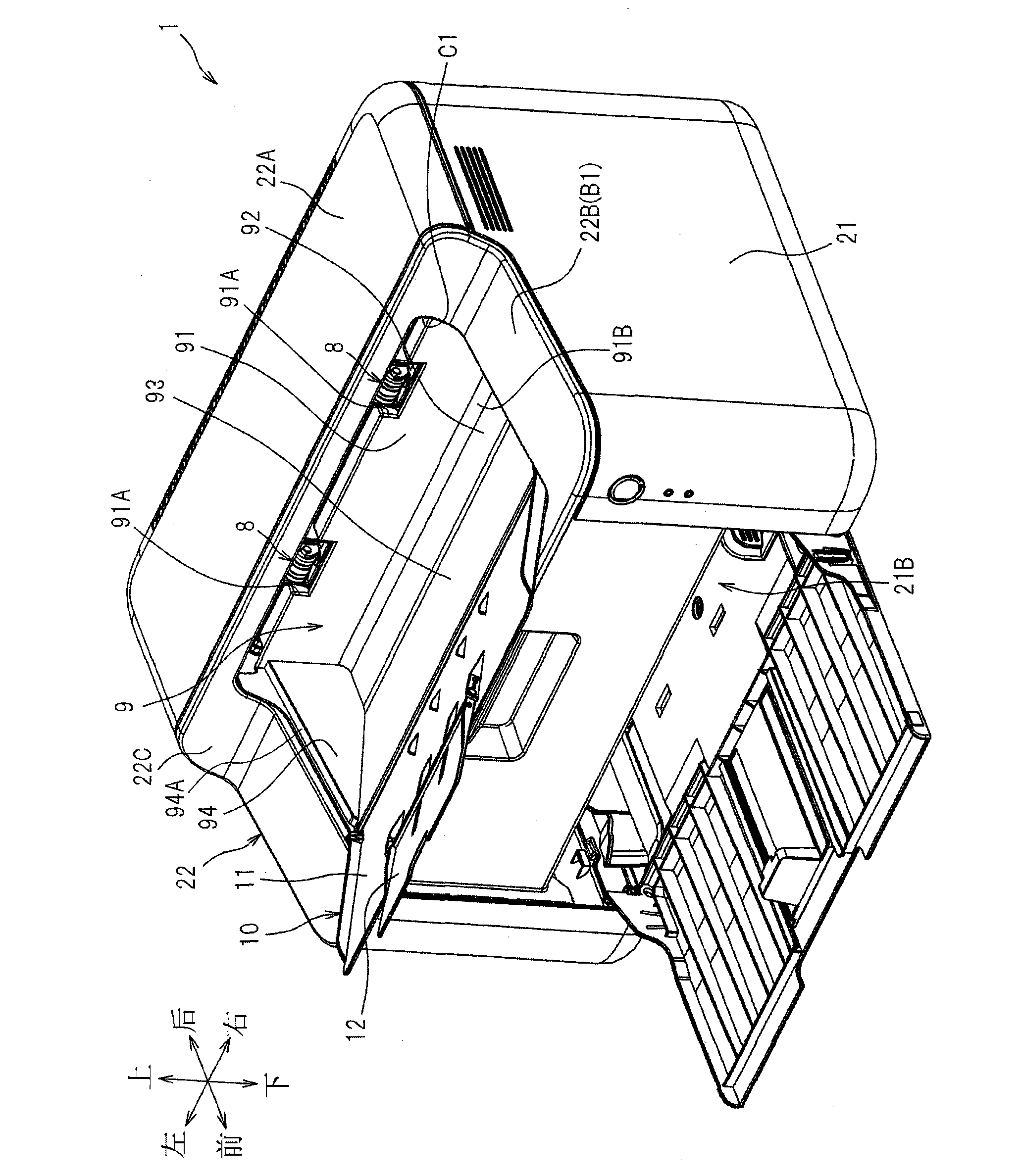

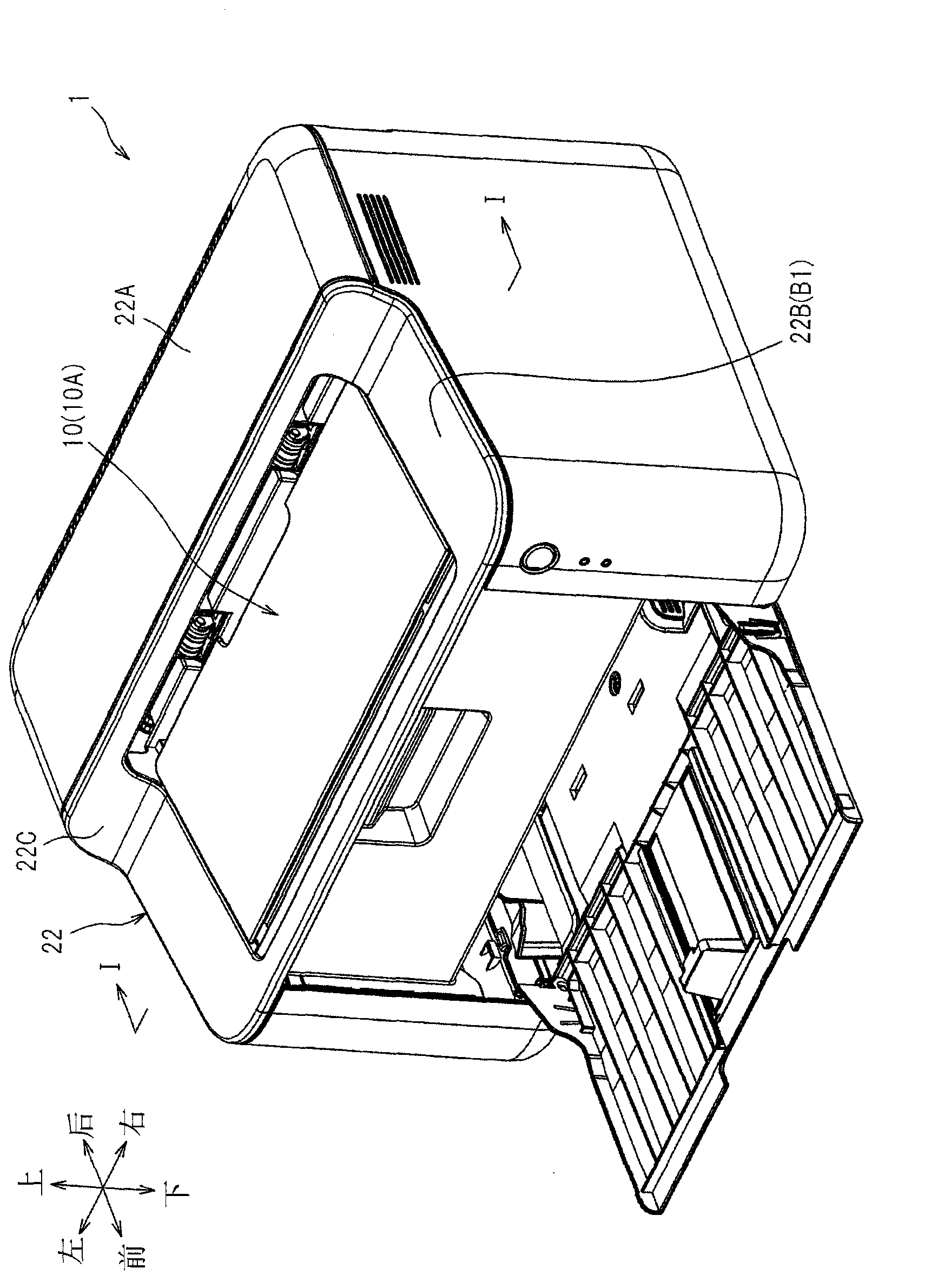

[0016] An exemplary embodiment will be described in detail with reference to the accompanying drawings. Hereinafter, a general structure of a laser printer as an example of an image forming apparatus will be described, and then features of the present invention will be described in detail.

[0017] Hereinafter, the direction or side of the laser printer will be based on the orientation in which the laser printer is placed to be used. In other words, in figure 1 In , the left side is called the front or front side, the right side is called the back or rear side, the upper side is called the upper side or the upper side, and the lower side is called the lower side or the lower side. The up and down direction may be referred to as a vertical direction.

[0018] Such as figure 1 As shown, the laser printer 1 includes a main body 2 , a supply section 3 for supplying a sheet P as an example of a recording sheet, and an image forming section 4 for forming an image on the sheet P. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com