Cooking utensil and method for making the same

A technology of cooking utensils and preforms, which is applied to the structure of cooking utensils, kitchen utensils, household utensils, etc., and can solve problems such as tarnishing and burnt appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to have a more complete and clear disclosure of the invention purpose, technical means and technical effects of the present invention, a detailed description is given below, and please also refer to the accompanying drawings and component numbers.

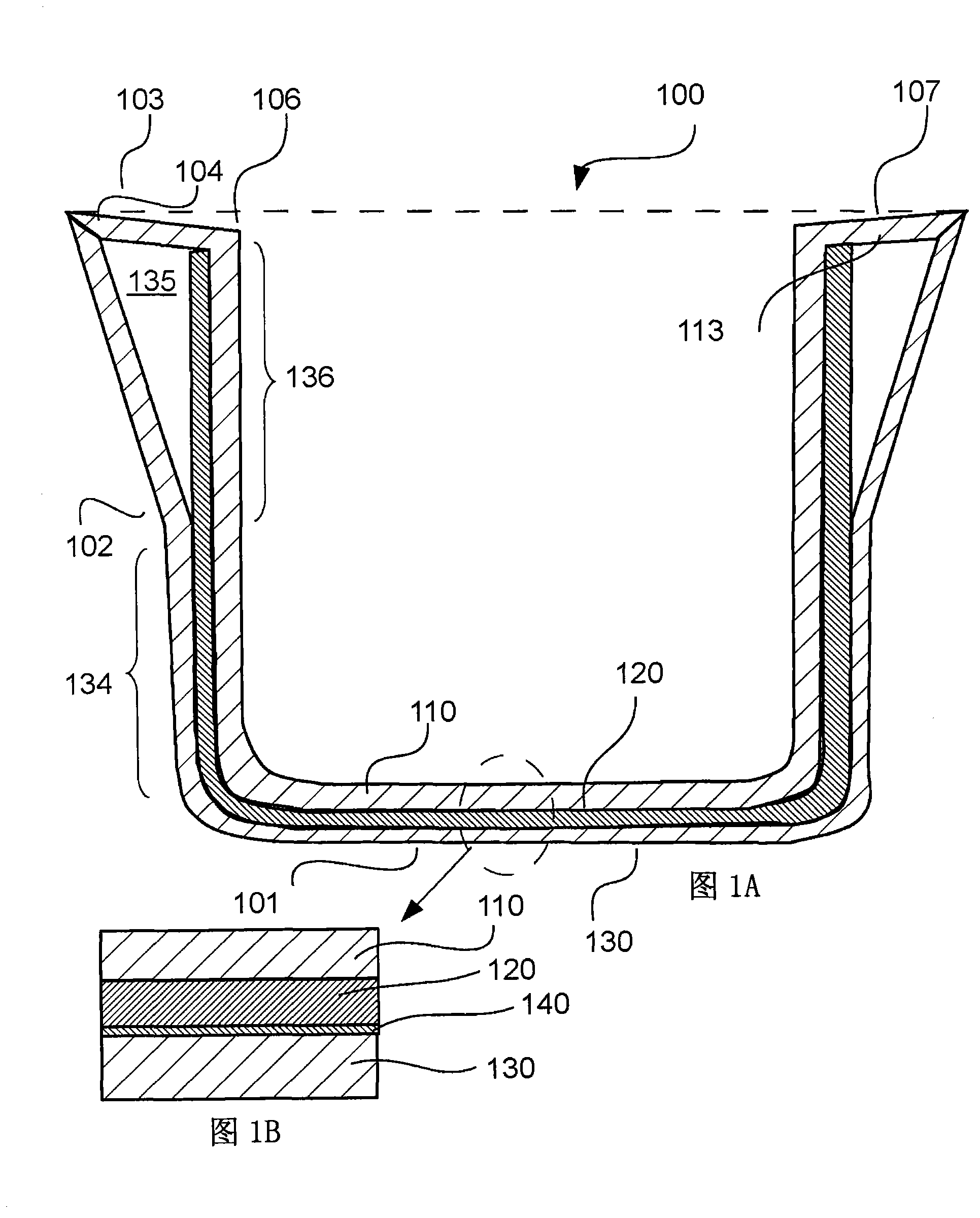

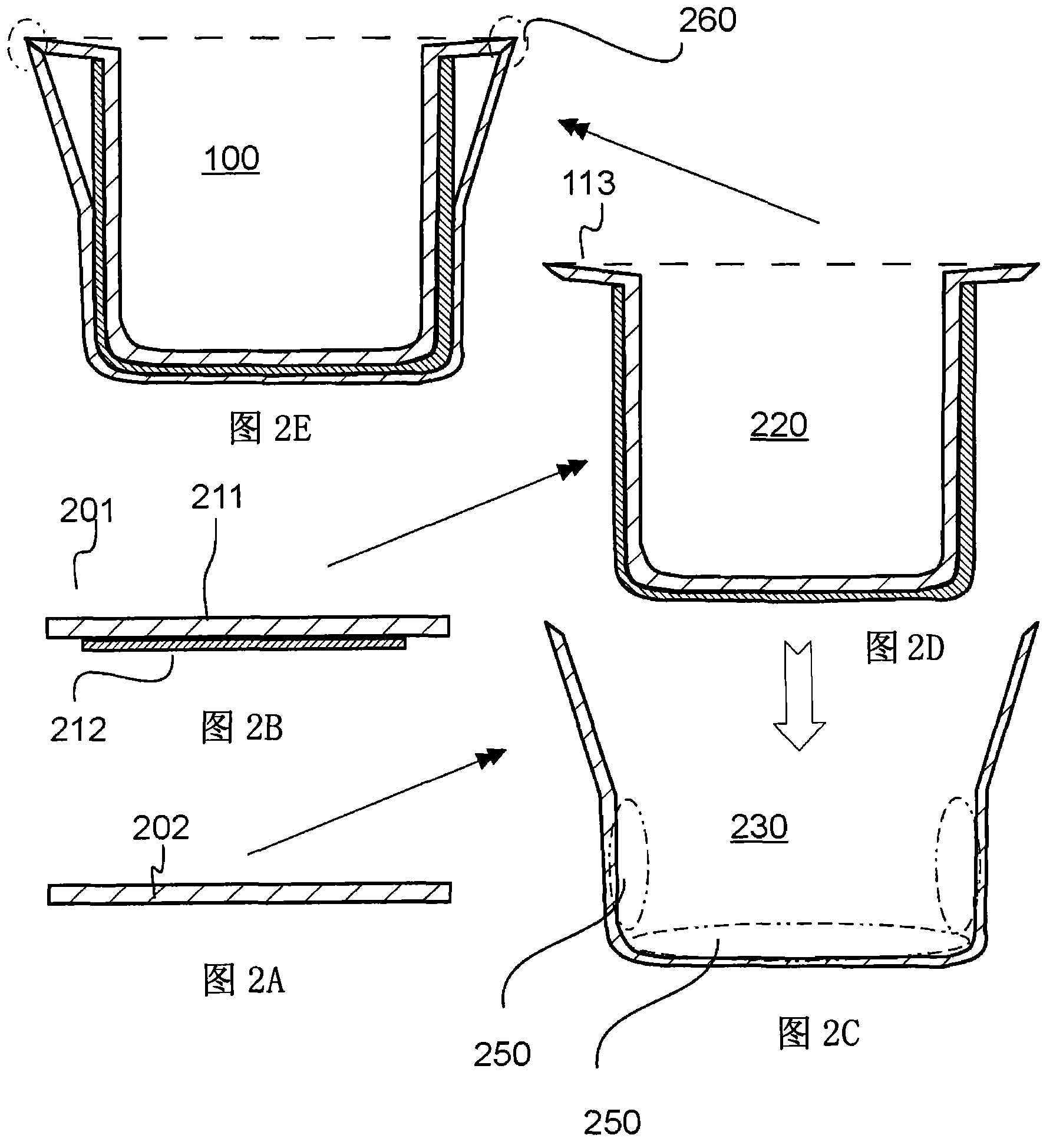

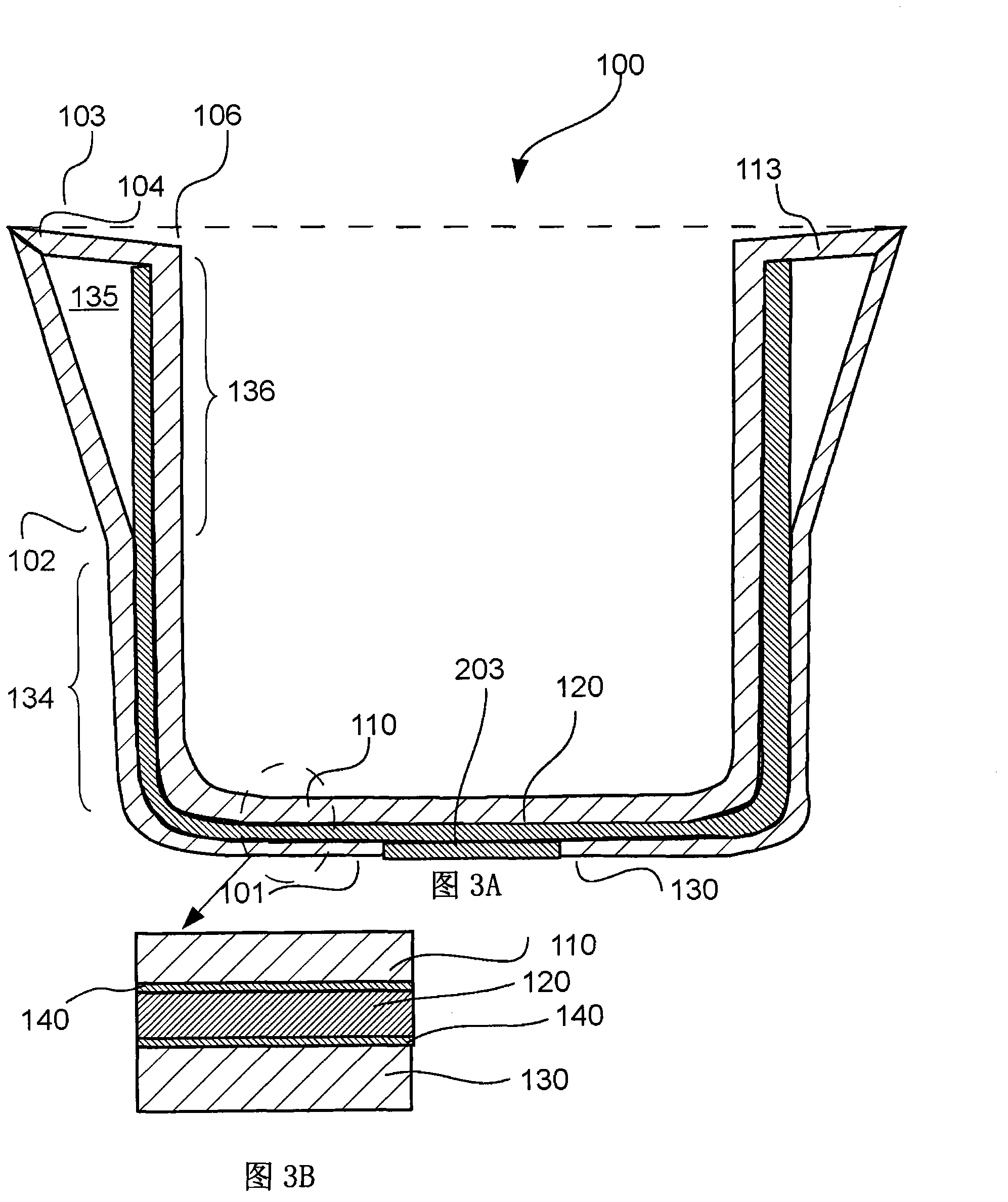

[0030] Referring to FIGS. 1 to 6 , wherein like reference numerals indicate like components in the different views, there is illustrated a new and improved partially insulated cooking appliance, generally indicated herein at 100 .

[0031] The cooking appliance 100 according to the invention has a bottom cooking surface 101 directly exposed to a heat source. A vertical wall 102 connects to and surrounds the bottom 101 and extends upwards to an edge region 103 . The lower portion 134 of the vertical wall 102 is a layered structure having three layers 130 , 120 and 110 . In the upper portion 136 of the wall 102, the outer layer 130 is separated from the more thermally conductive inner layer 120 to form a cavity 135 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com