Ferrite three-stage three-phase permanent magnet motor

A permanent magnet motor, three-stage technology, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuits, electrical components, etc., can solve the problems of large copper consumption and high cost, and achieve material minimization and high The effect of operating speed and air gap minimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

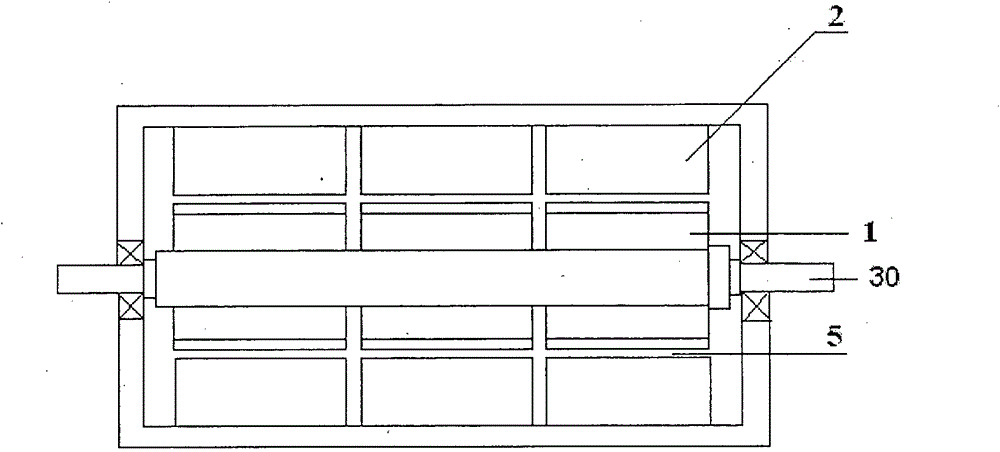

[0023] Such as figure 1 Shown is a preferred embodiment of the present invention, the main components of this ferrite three-stage three-phase permanent magnet motor include a rotor 1, a stator 2, a rotating shaft 30, etc., and the physical air gap 5 between the rotor 1 and the stator 2 is 0.5~3.0mm. The stator core is a three-stage structure made of soft ferrite, and the A, B, and C three-phase windings each occupy the first, second, and third sections;

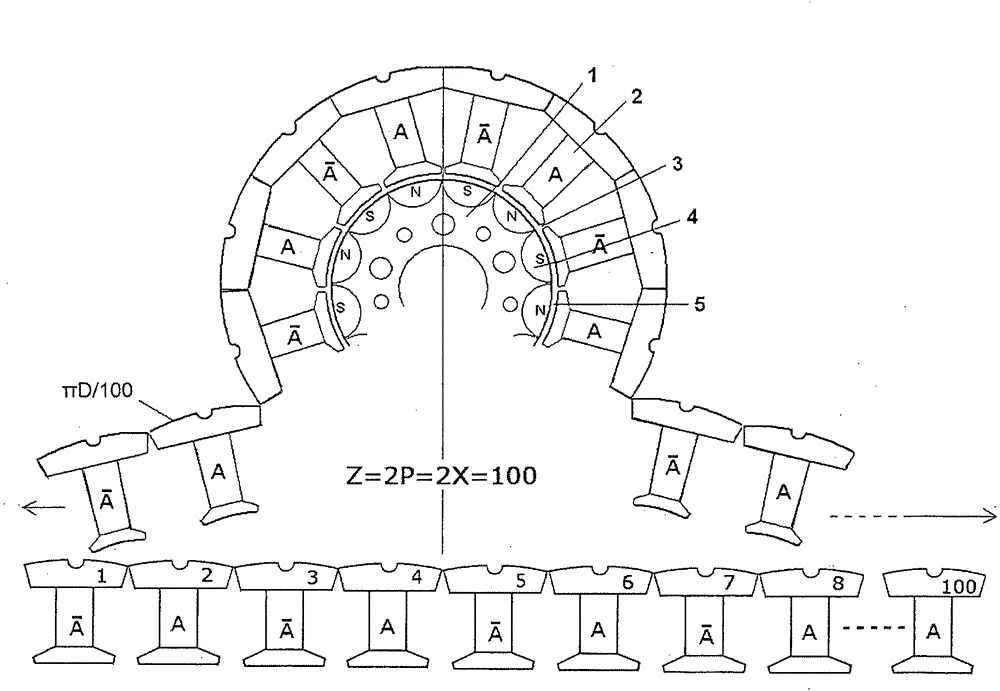

[0024] In the following embodiments, X=50 is taken, so Z=2P=2X=100; during specific implementation, any value among X=21, 22, 23, . . . 100 can also be taken. Such as figure 2 As shown, in the following descriptions, phase A is taken as an example. The first section of the stator core is composed of 100 teeth 40 made of independent soft ferrite, so the number of slots of the stator Z=100.

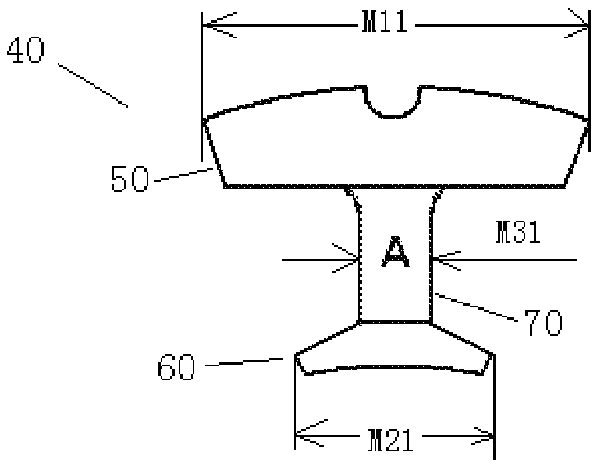

[0025] Such as image 3 and Figure 4 As shown, the relationship between the width M11 of the outer circle end 50 of each tooth 40,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com