A Valve Sleeve with Automatic Gap Compensation

A gap compensation and valve sleeve technology, applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of high water rigidity, easy leakage of hydraulic components, low viscosity, etc., to reduce leakage, overcome difficult processing, Simple and convenient processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

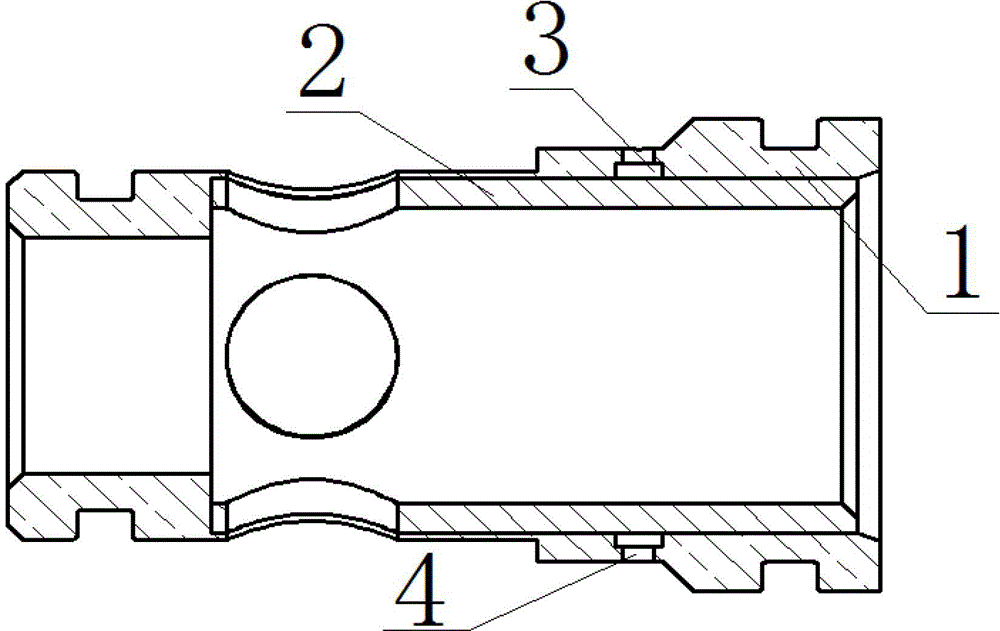

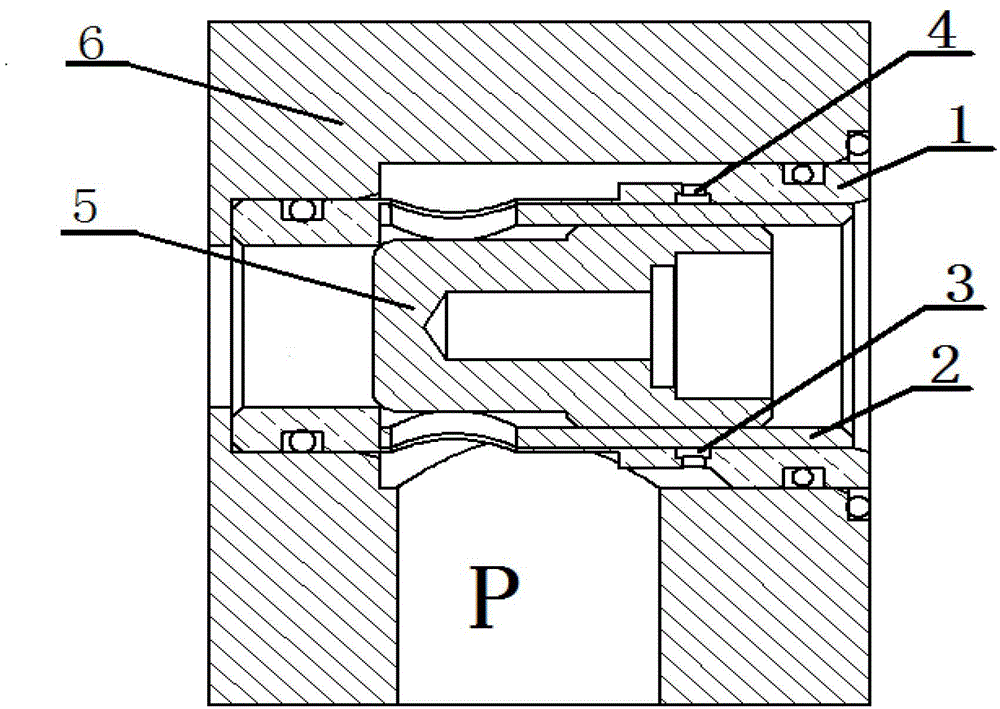

[0013] figure 1 It is a structural diagram of the present invention, which includes a valve sleeve base (1), an elastic sleeve (2), an annular groove (3), and a circumferential hole (4); the elastic sleeve (2) is an elastic element, which is injected into the valve The sleeve base (1) makes the two form an assembly, and the valve core (5) is inserted into the elastic sleeve to fit with the gap; the inner surface of the valve sleeve base (1) has an annular groove (3), and on the valve sleeve base (1) There are four evenly distributed circumferential holes (4) connected with the annular groove (3) along the circumferential direction. With the increase of the number of circumferential holes (4), the force of the elastic sleeve (2) will be more uniform. The elastic sleeve (2) is an engineering plastic elastic element, and its material is PEEK.

[0014] When working, the fluid medium enters the annular groove (3) through the circumferential hole (4). The circumferential hole and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com