In-pipe packer for tightness detection of oil casing

A sealing detection and packer technology, which is used in sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problems of different inspection accuracy and air tightness requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

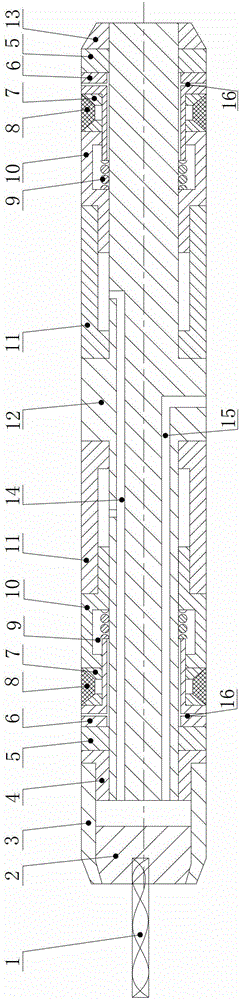

[0022] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0023] see figure 1 , an in-pipe packer for oil-casing tightness testing, including a main body 12, the main body adopts a vertically symmetrical central axis structure, and a connecting sleeve 11, a piston sleeve 10, a piston shaft 6 and an adjusting sleeve are sequentially symmetrically assembled in the middle of the main body. Set of 5. One end of the body is provided with a locking sleeve 13 for preventing axial movement of the piston shaft when the packer is set, and the other end of the body is provided with a locking head for preventing axial movement of the piston shaft when the packer is set 4. The locking sleeve 13, the locking head 4 and the adjusting sleeve 5 form a double-nut tightening structure to prevent the piston shaft 6 fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com