Air tightness detector for soft packaging bags and boxes filled with liquid and detection method thereof

A technology for air tightness testing and flexible packaging bags, which is applied in the directions of measuring devices, fluid tightness testing, machine/structural component testing, etc. It can solve the problems of no public airtightness testing and achieve low cost, positive technical effects, The effect of simple detection methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

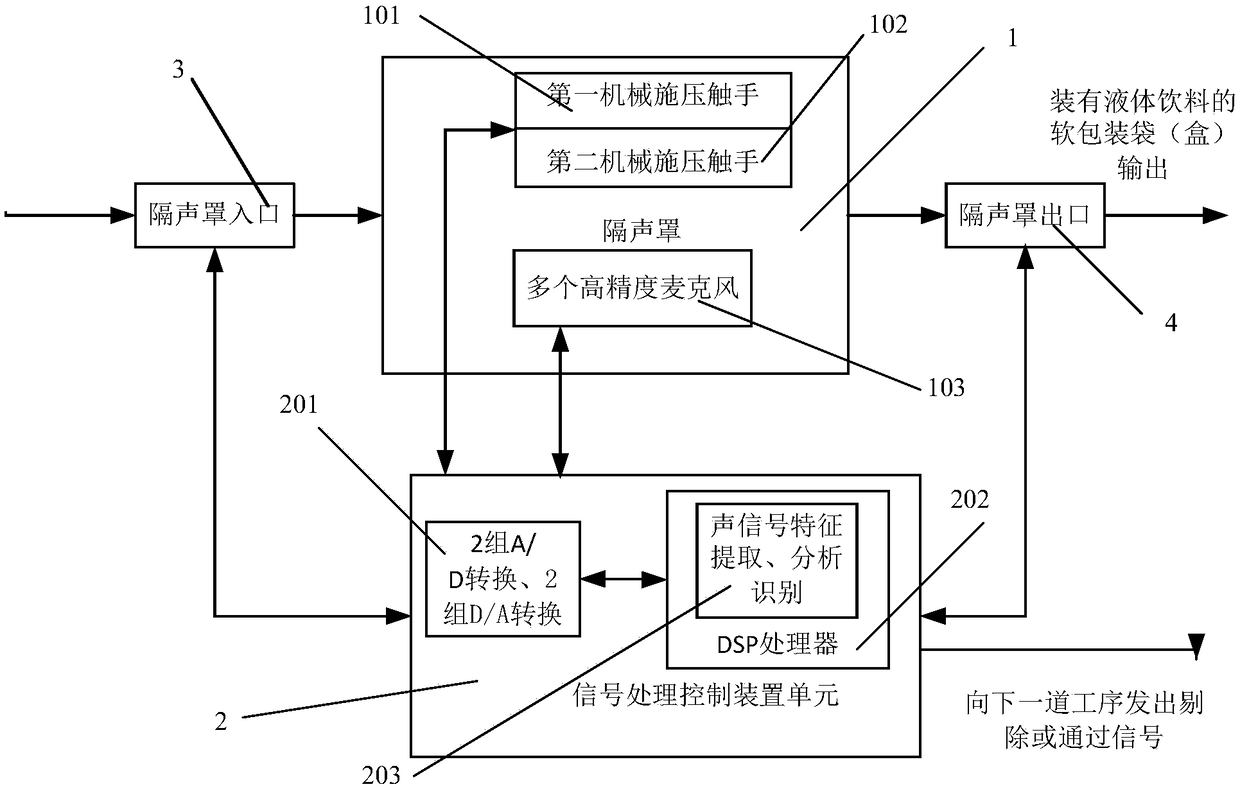

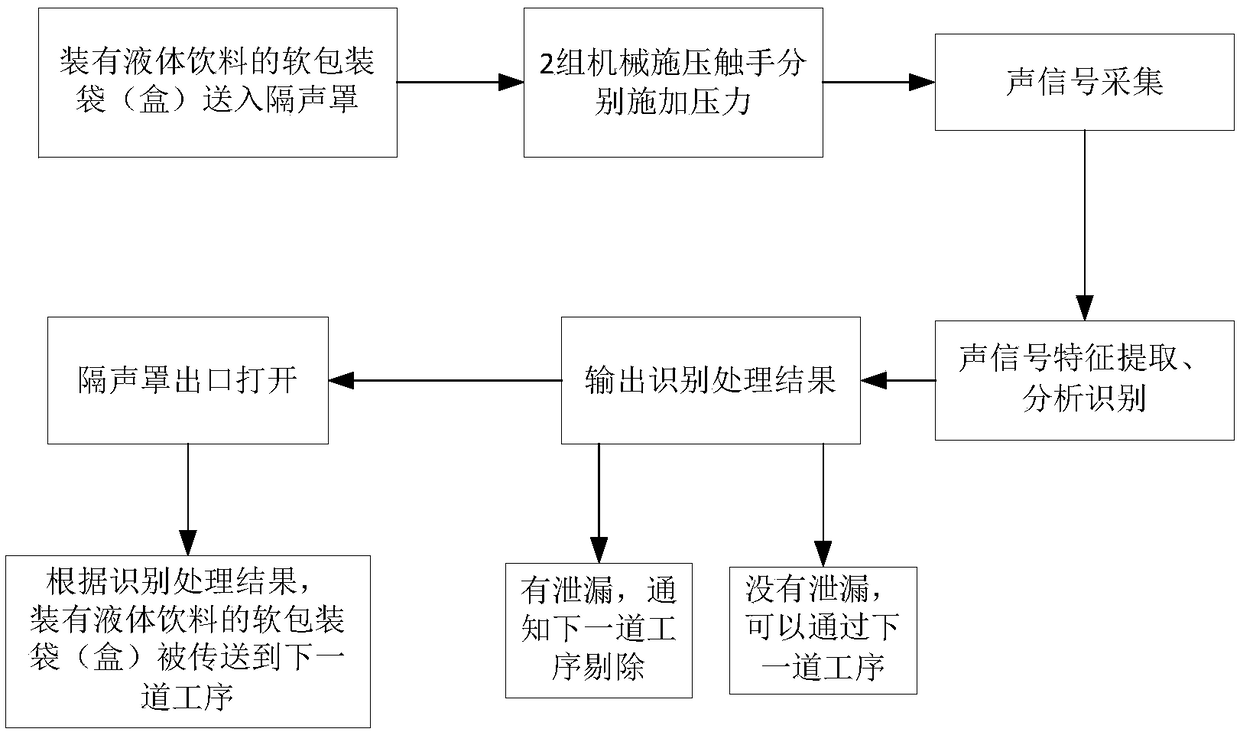

Method used

Image

Examples

Embodiment

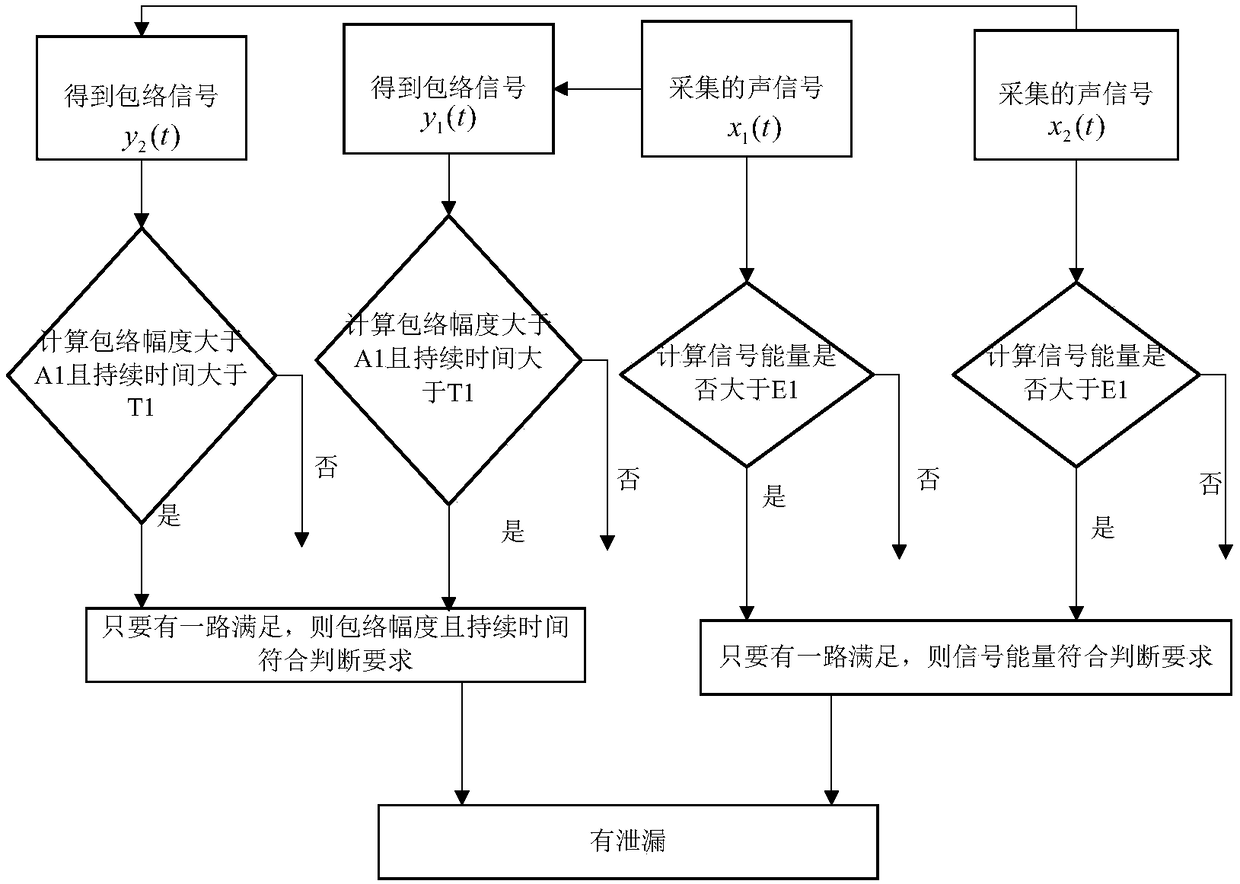

[0048] Example: In a quiet environment, pressure is applied to the packaging bag box containing the liquid with the leakage point, and the acoustic signal test when the leakage occurs is actually collected. Leakage points can be made artificially, and the leakage can be formed by puncturing the hole with a needle or drawing the liquid with a medical syringe. When there is a leak, the acoustic signal collected by the microphone and Cooledit software has a sampling rate of 44.1KHz and 16 bits. Two kinds of acoustic signals are obtained by applying pressure to two different liquid-filled packaging boxes. The analysis results show that the collected acoustic signals caused by leakage have common characteristics. Therefore, the detection method of the present invention is reliable. The test results are as follows:

[0049] Figure 4 It is a time-domain waveform of the acoustic signal 1 collected when the beverage box has a leak, Figure 5 Is the time-frequency distribution diagram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com