Automatic hydraulic slip

A fully automatic and hydraulic technology, which is applied to drilling equipment, earthwork drilling, drilling pipes, etc., can solve the problems of low automation, poor compatibility, and inability to adapt to pipe strings, etc., and achieves high automation, simple and safe operation, and realization of The effect of manual lubrication and automatic lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

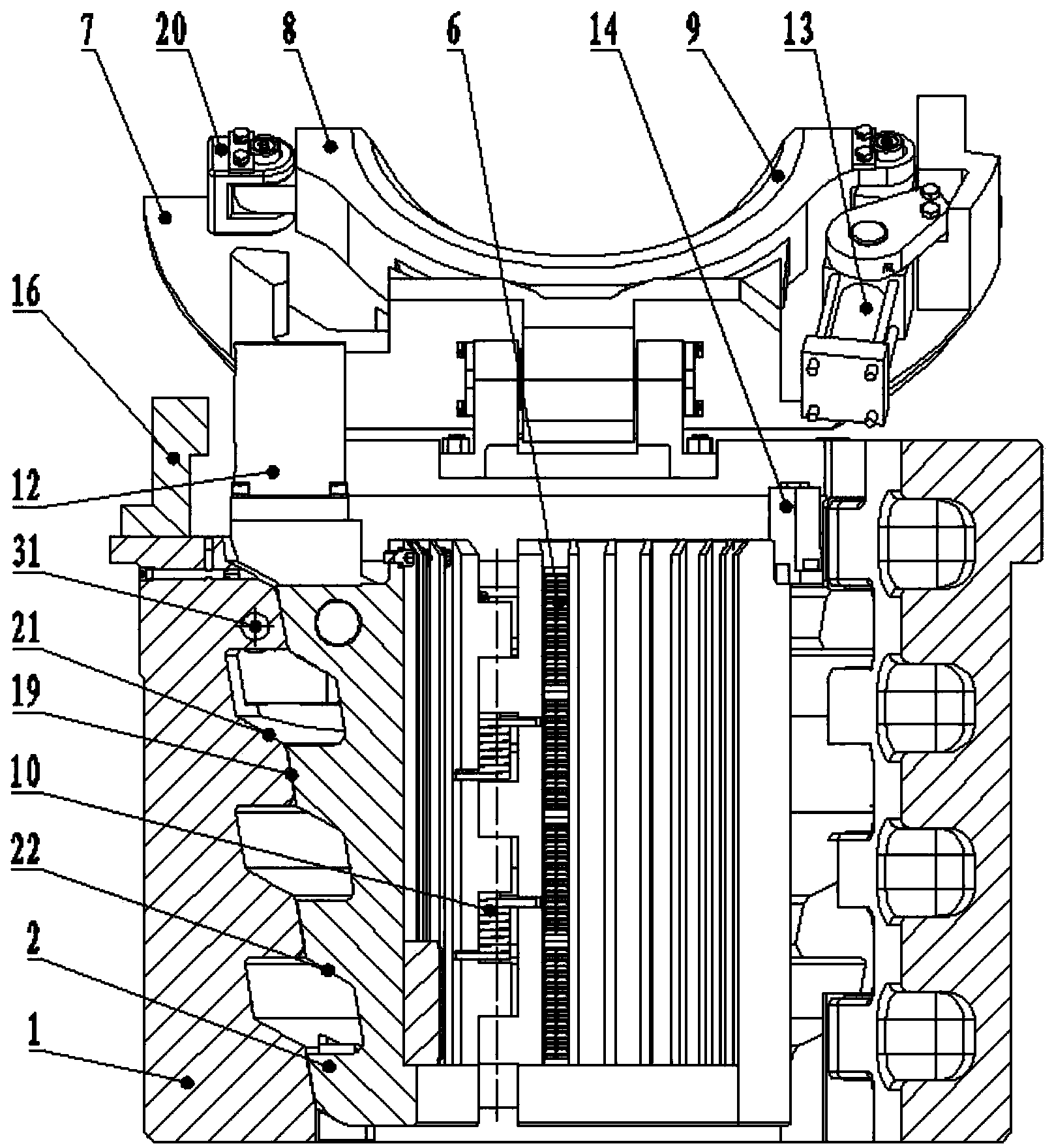

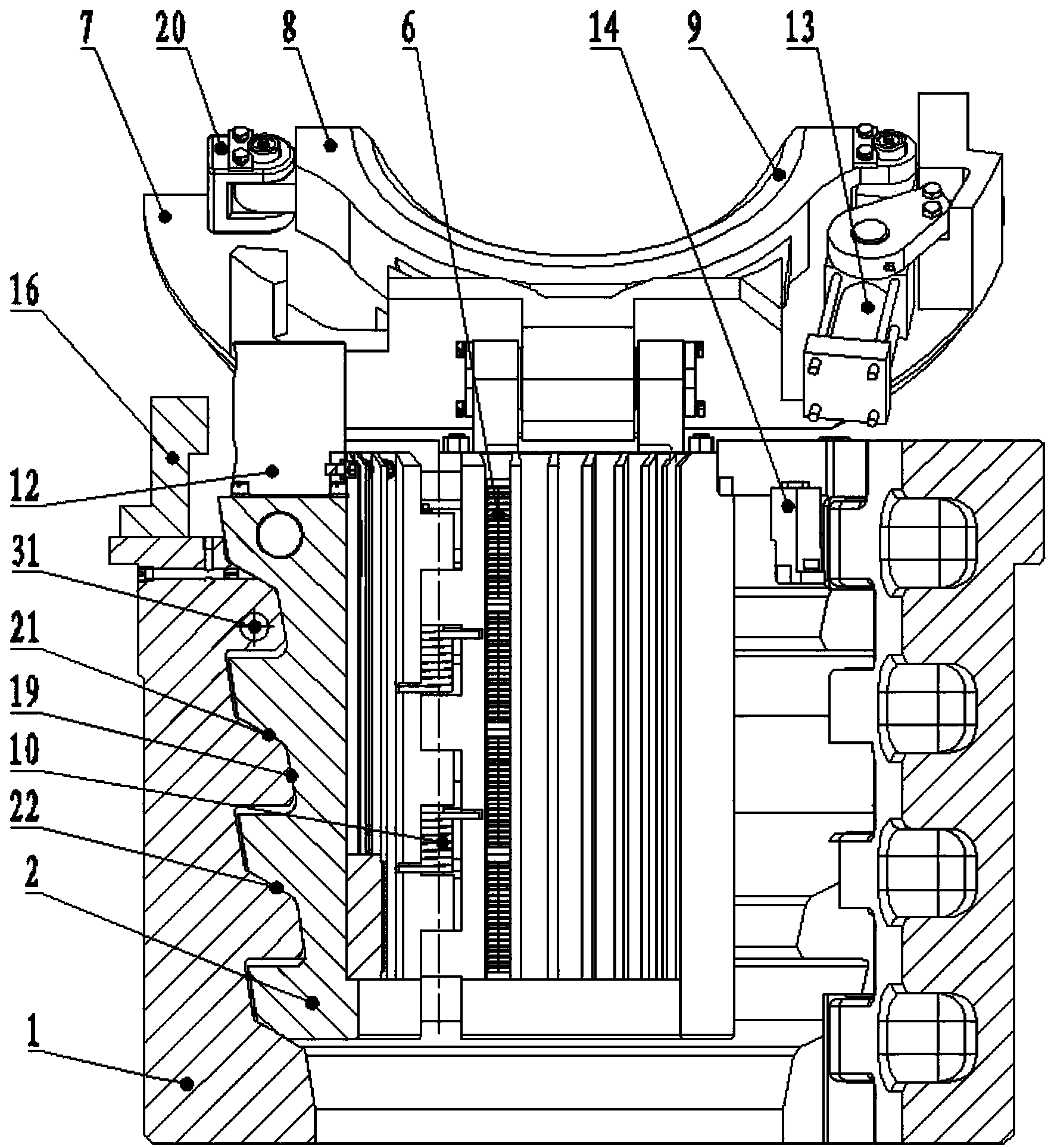

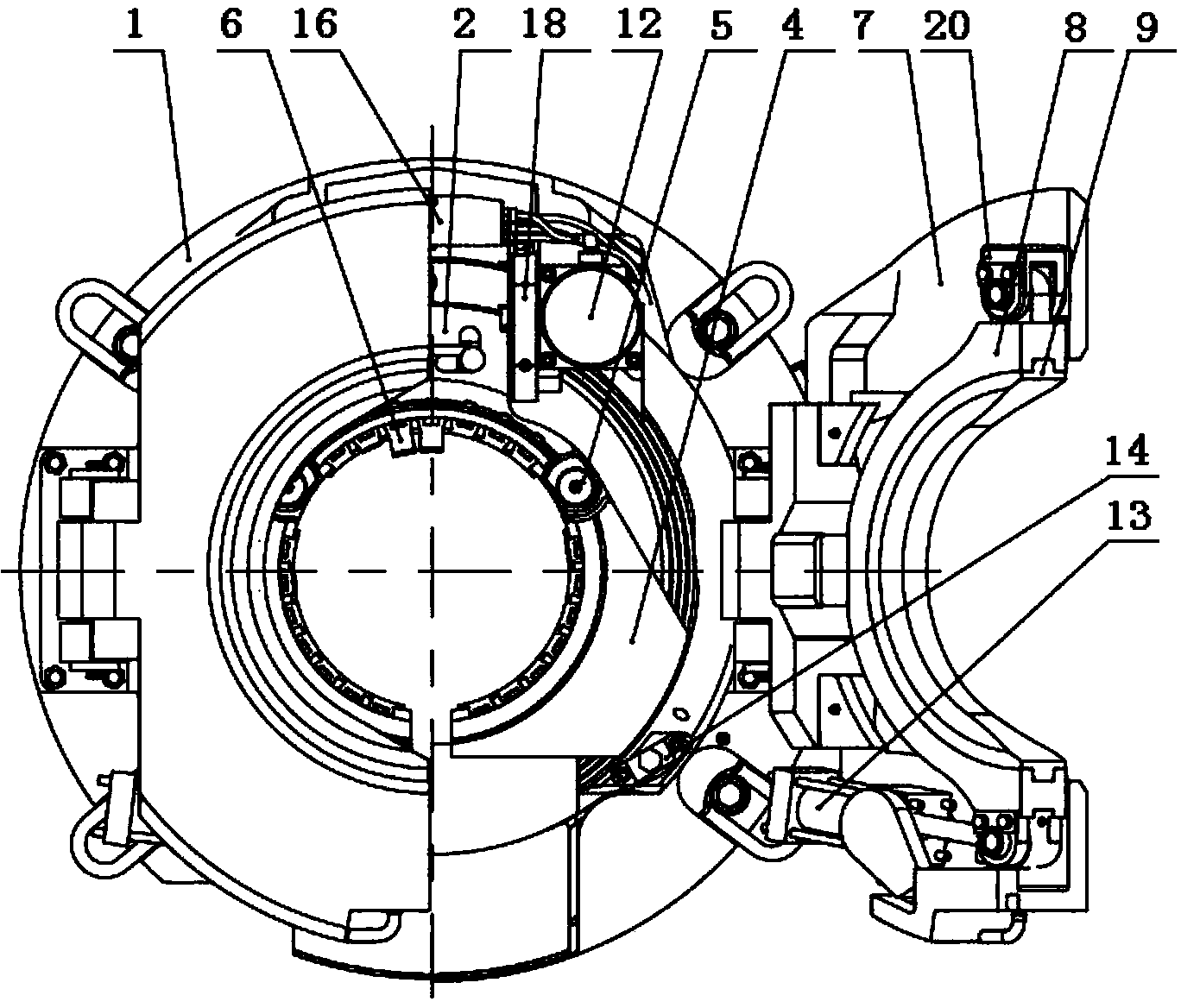

[0020] The structure of the fully automatic hydraulic slips of the present invention is that it includes a slip seat, three slip bodies, a two-petal clamping mechanism and a control mechanism, and the top cover of the clamping mechanism is equipped with a replaceable top ring clamp. And the matching top ring. The slip seat and the top cover are respectively equipped with corresponding hydraulic cylinders and integrated valve blocks, which are respectively connected to the corresponding components in the hydraulic control box 34 through their respective quick connectors; the hydraulic control box 34 is equipped with sequence valves and electromagnetic reversing valve Hydraulic components such as hydraulic components and PLC finally carry out remote operation through the control panel 35 of the driller's room.

[0021] figure 1 It is a struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com