Variable-cross-section concrete continuous bridge construction method

A construction method and concrete technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increasing project cost, increasing bridge scale, and small construction technology, reducing the project scale and reducing the span beam. The effect of high and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail by taking the construction method of a three-span variable-section concrete continuous girder bridge as an example below. The following examples can enable those skilled in the art to understand the present invention more comprehensively, but do not limit the present invention in any way.

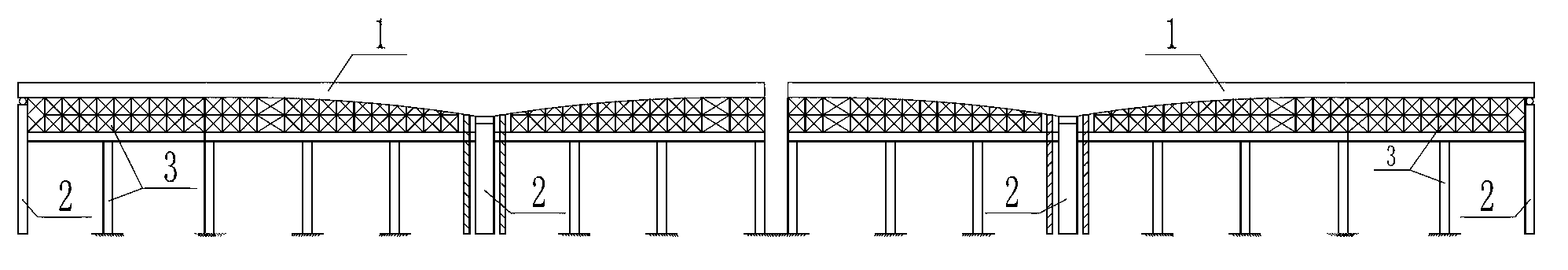

[0026] The first stage is to construct the beam body 1 except for the mid-span and closing section on the full-wall support, which specifically includes erecting the full-wall support of the beam body to be constructed, preloading the support, erecting formwork, binding ordinary steel bars, erecting prestressed steel beam bellows, Pouring beam concrete and curing; such as figure 1 shown.

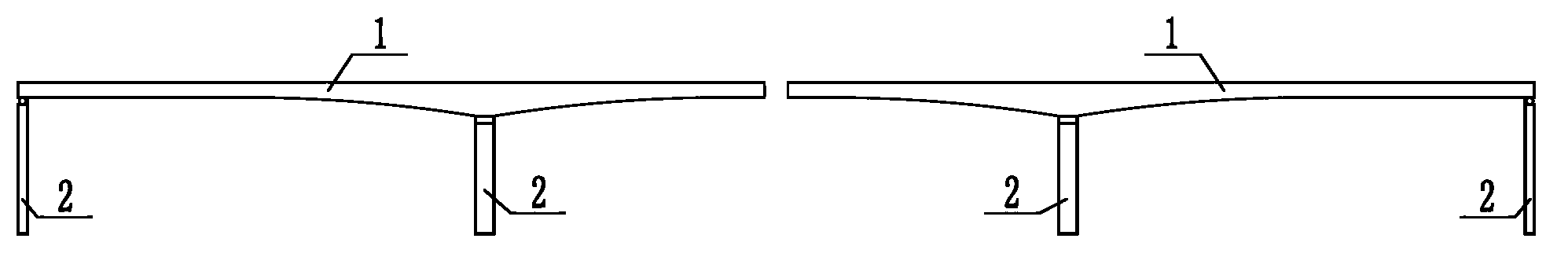

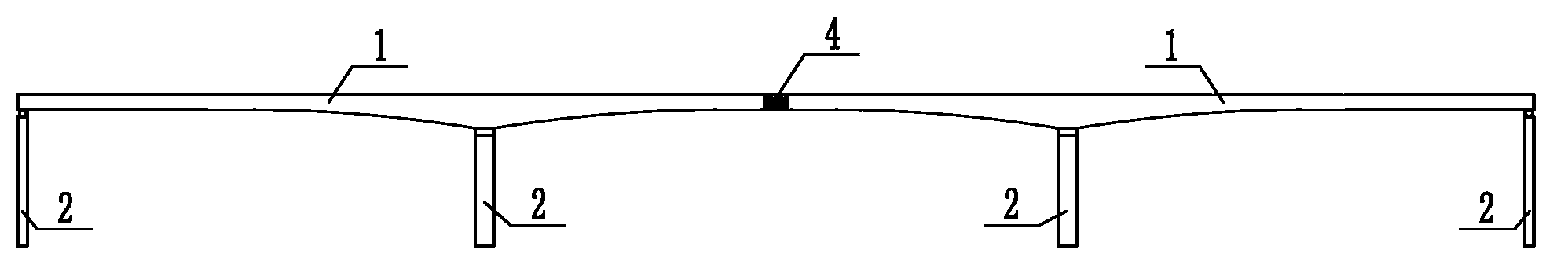

[0027] The second stage is to analyze the load of the beam body 1 except the mid-span closure section according to the stress state of the cantilever beam. According to the load analysis, carry out the first cross-section reinforcement for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com