Spunlaced non-woven material, manufacturing method, manufacturing equipment and hygienic wet tissue

A technology of non-woven materials and manufacturing equipment, applied in the field of non-woven manufacturing, can solve the problems of inability to achieve dispersion, allergic reactions of users, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present application will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

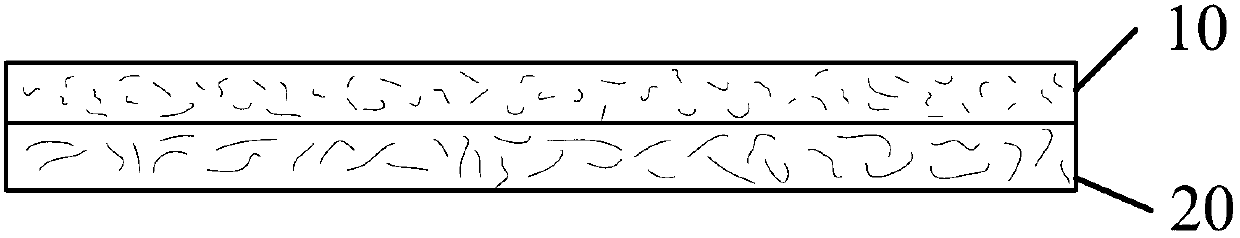

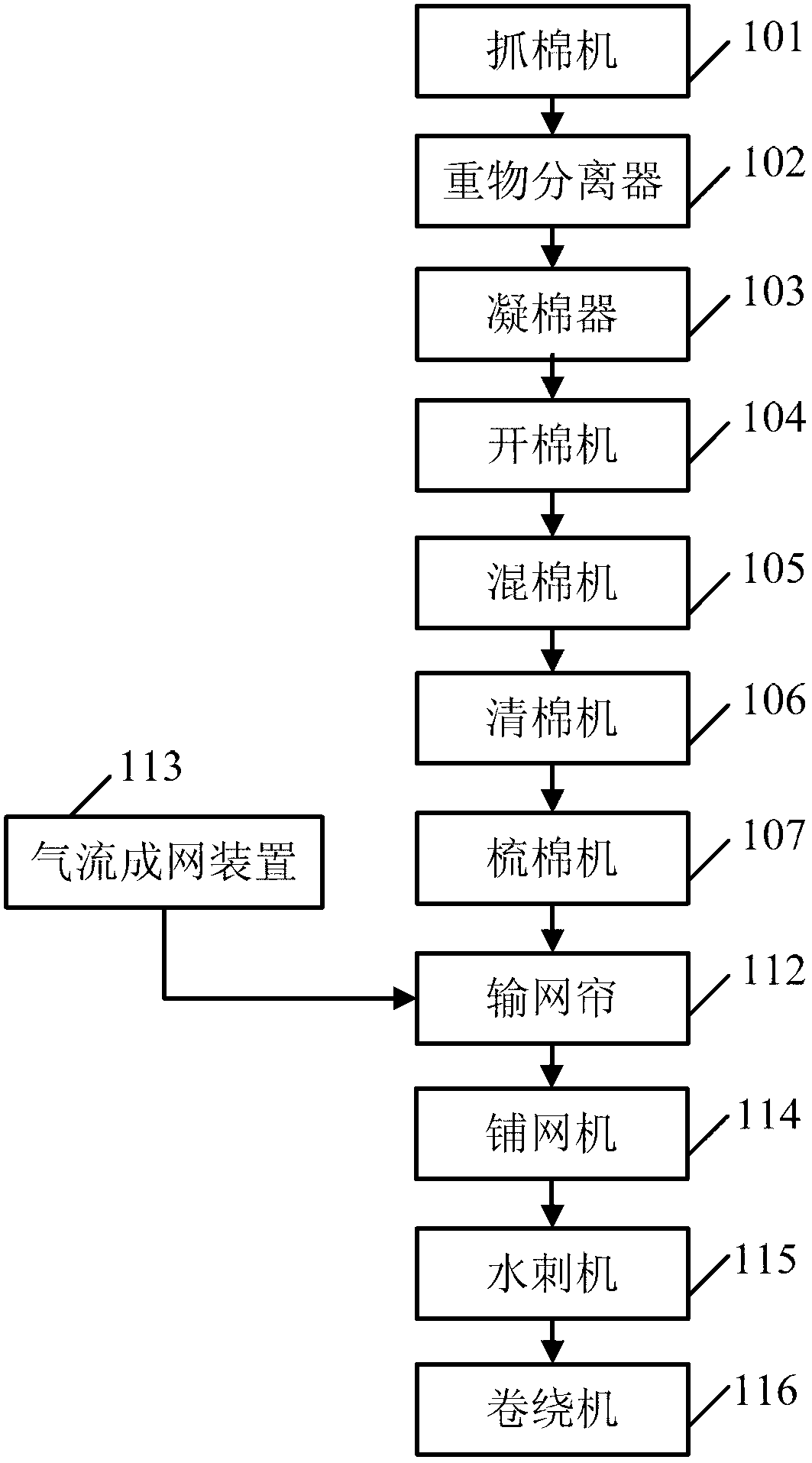

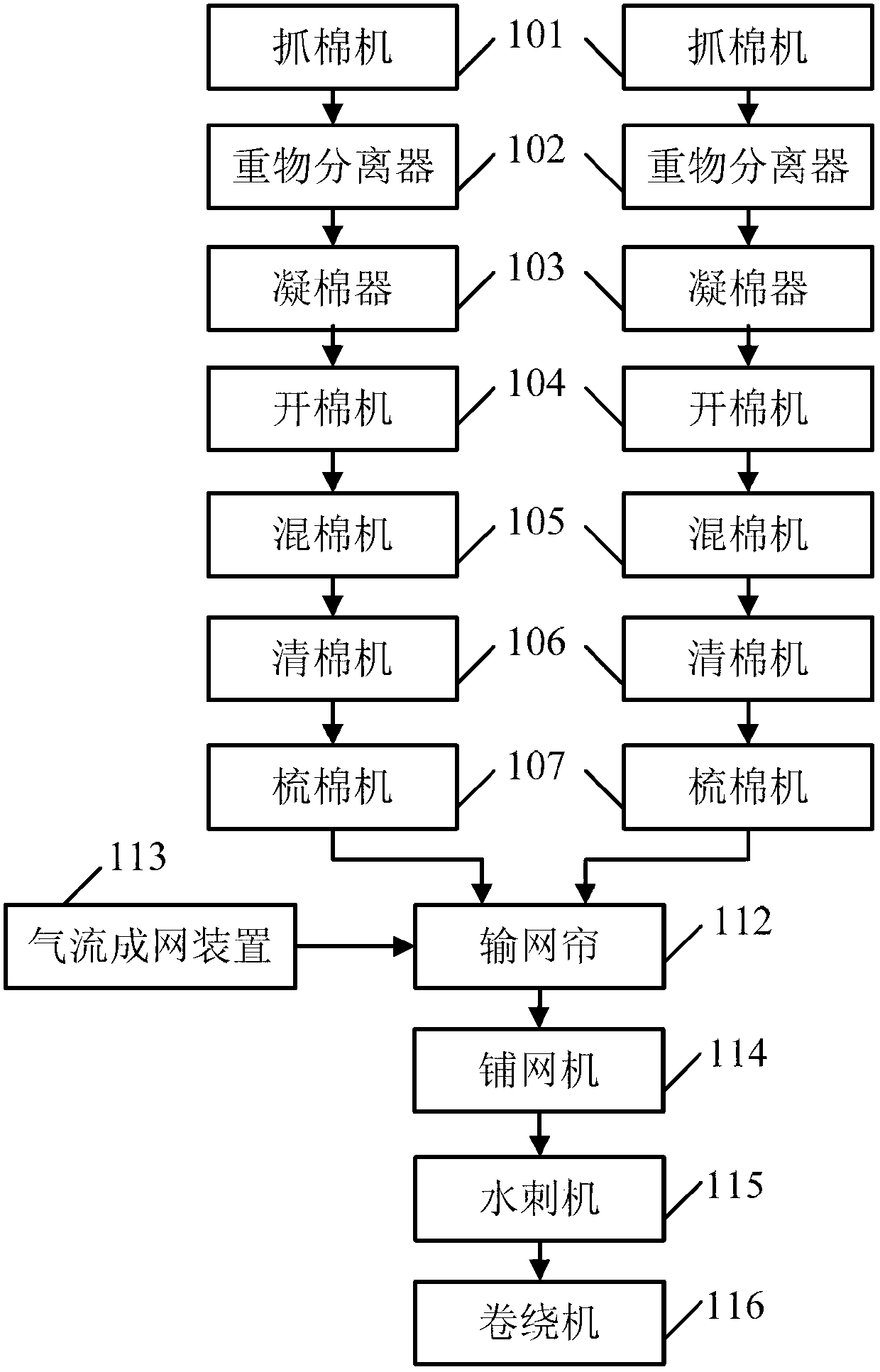

[0041] Please refer to figure 1 , the embodiment of the present application provides a spunlace nonwoven material, comprising a long fiber layer 10 with a fiber length of 10-80mm and a short fiber layer 20 with a fiber length of 0-8mm, the short fiber layer 20 is consolidated on the On the long fiber layer 10, when the spunlace nonwoven material is in water, the short-pile fibers in the short fiber layer 20 are washed away by water, because the short fiber layer 20 is entangled on the long fiber layer 10 by water entanglement, so Lead to the disintegration of the material structure, so as to achieve the effect of dispersion. The spunlace nonwoven material provided by the embodiment of the present application is different from the material made by using an adhesive, and its dispersion effect will not be affected by the environme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com