Vortex composite spinning method for producing structured yarns

A technology of vortex spinning and composite spinning, applied in the field of textile processing, can solve the problems of inability to achieve multi-color and multi-form wrapping of filament yarns, waste of raw materials, and poor fiber cohesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below in conjunction with accompanying drawing

[0013] see Attachment

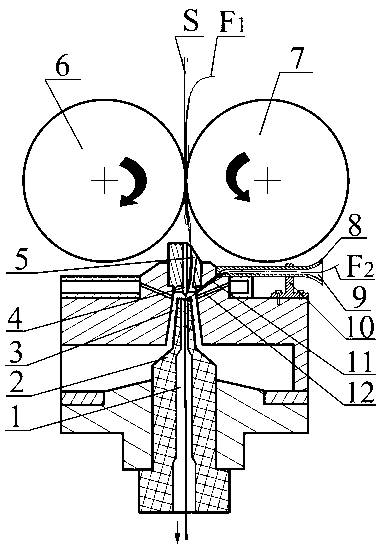

[0014]A vortex composite spinning method for producing fancy yarns, in which a yarn conveying channel 11 is arranged on the outer tube of each vortex spinning device of a vortex spinning machine, and the yarn conveying channel 11 is located in the gas conveying pipeline 12 and the fiber conveying channel 5 In between, the yarn delivery channel 11 is on the same side as the front rubber roller 7, so that the decorative yarn F2 can be guided and fed smoothly. The angle between the central axis of the yarn delivery channel 11 and the central axis of the guide pin 4 is 15-65°. The yarn outlet is located between the fiber outlet of the fiber delivery channel 5 and the yarn inlet of the yarn channel 1. The purpose is that after the decorative yarn F2 is fed into the vortex chamber 3, it can smoothly enter the yarn channel 1 under the action of air...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com