Inorganic damping composite material and preparation method thereof

A technology of damping composite materials and inorganic materials, applied in the field of damping composite materials, can solve the problems of insufficient damping effect, and achieve the effects of reducing vibration, eliminating noise and improving the damping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

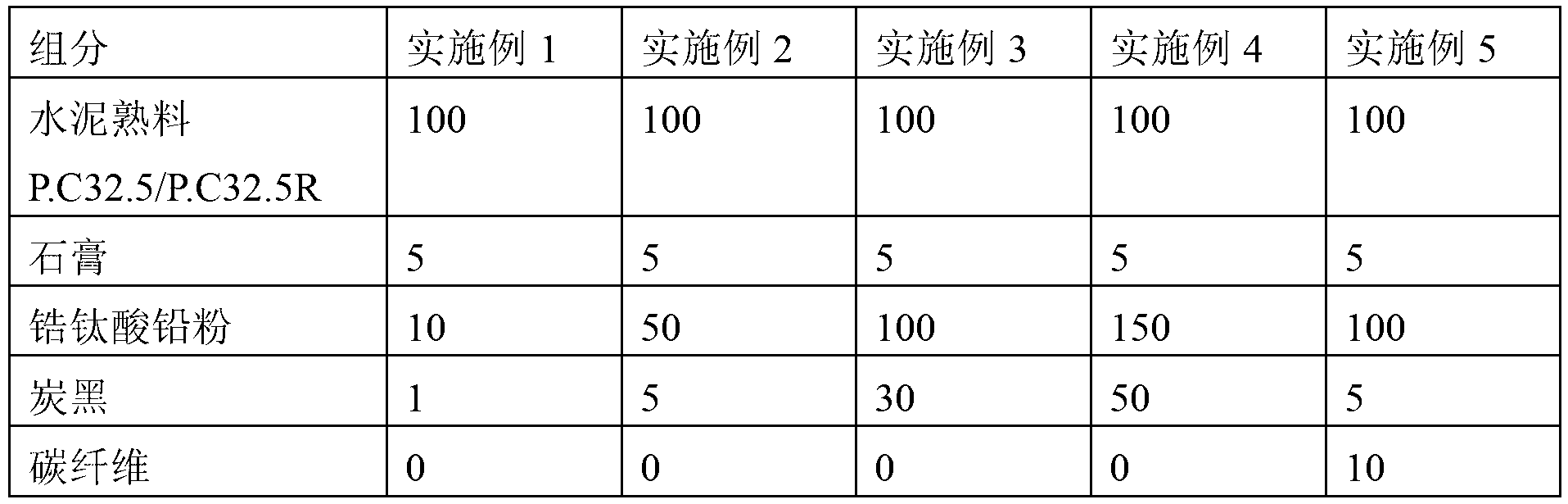

Embodiment 1

[0038] Take 100 parts by weight of cement clinker, the cement clinker model is P.C32.5 / P.C32.5R, add the dry lead zirconate titanate powder that has been treated with silane coupling agent in advance and cleaned with ethanol aqueous solution, and then add Mix one or several kinds of conductive fillers with gypsum evenly, stir mechanically at room temperature for 10 minutes, put the mixture into an ultrasonic oscillator, and ultrasonically mix at 90°C and 80Hz for 2 hours. After curing and molding at room temperature, the sample Put it in a DC oil bath electric field for polarization, the polarization temperature is 100°C, the polarization voltage is 10km / mm, and the polarization time is 120min, then put the sample into 1.0Hz, 500mN, room temperature to 200°C for dynamic Mechanical analysis, and mechanical performance testing. Embodiment 1~5 formula is as shown in table 1, and the damping performance of gained piezoelectric damping composite material is as, mechanical property ...

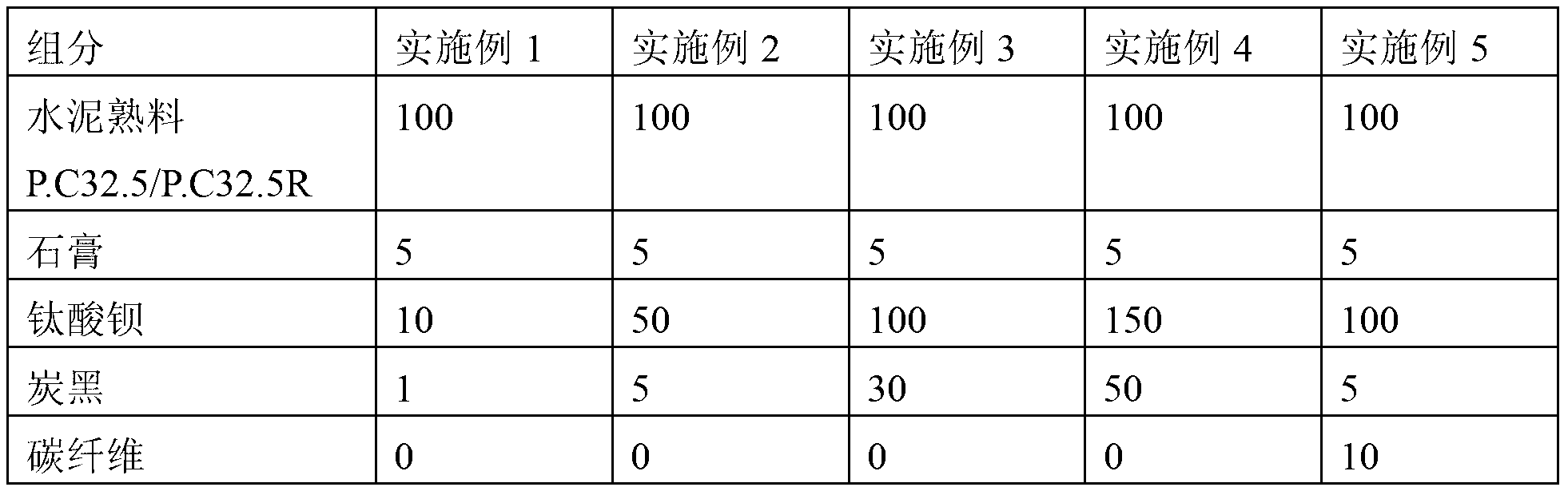

Embodiment 6~10

[0040] Take 100 parts by weight of cement clinker, the cement clinker model is P.O42.5 / P.O42.5R, add dry barium titanate that has been treated with silane coupling agent in advance, and washed with ethanol aqueous solution, and then add conductive filler And the gypsum is mixed evenly, mechanically stirred at room temperature for 10 minutes, put the mixture into an ultrasonic oscillator, and vibrate at 90 ° C and 80 Hz for 2 hours. After curing and molding at room temperature, put the sample into a DC oil bath electric field for polarization The polarization temperature is 100°C, the polarization voltage is 10km / mm, and the polarization time is 120min, and then the sample is placed in 1.0Hz, 500mN, room temperature to 200°C for dynamic mechanical analysis and mechanical performance testing. The formulations of Examples 6-10 are shown in Table 3, and the damping properties and mechanical properties of the obtained piezoelectric damping composite materials are shown in Table 4. ...

Embodiment 11~15

[0042] Take 100 parts by mass of the prepared liquid asphalt, treat the lead zirconium titanate lanthanate powder with a silane coupling agent, and wash it with an aqueous ethanol solution. After drying, take a certain amount, then add a conductive filler, and stir the mixture mechanically for 10 minutes at room temperature. Put it into an ultrasonic oscillator, vibrate at 80°C and 90Hz for 3 hours, after curing and molding at room temperature, put the sample into a DC oil bath electric field for polarization, the polarization temperature is 60°C, and the polarization voltage is 10km / mm , the polarization time is 100min, and then put the sample into 1.0Hz, 500mN, room temperature to 200°C for dynamic mechanical analysis and mechanical performance test. The formulas of Examples 11 to 15 are as shown in Table 5, and the damping performance and mechanical properties of the obtained piezoelectric damping composite material are as shown in Table 6. The asphalt material obtained by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com