Pneumatic tire

A technology of pneumatic tires and tires, which is applied to tire parts, tire edges, wheels, etc., can solve the problems of reduced bead durability, bead damage, and large impact, and achieve the effect of improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

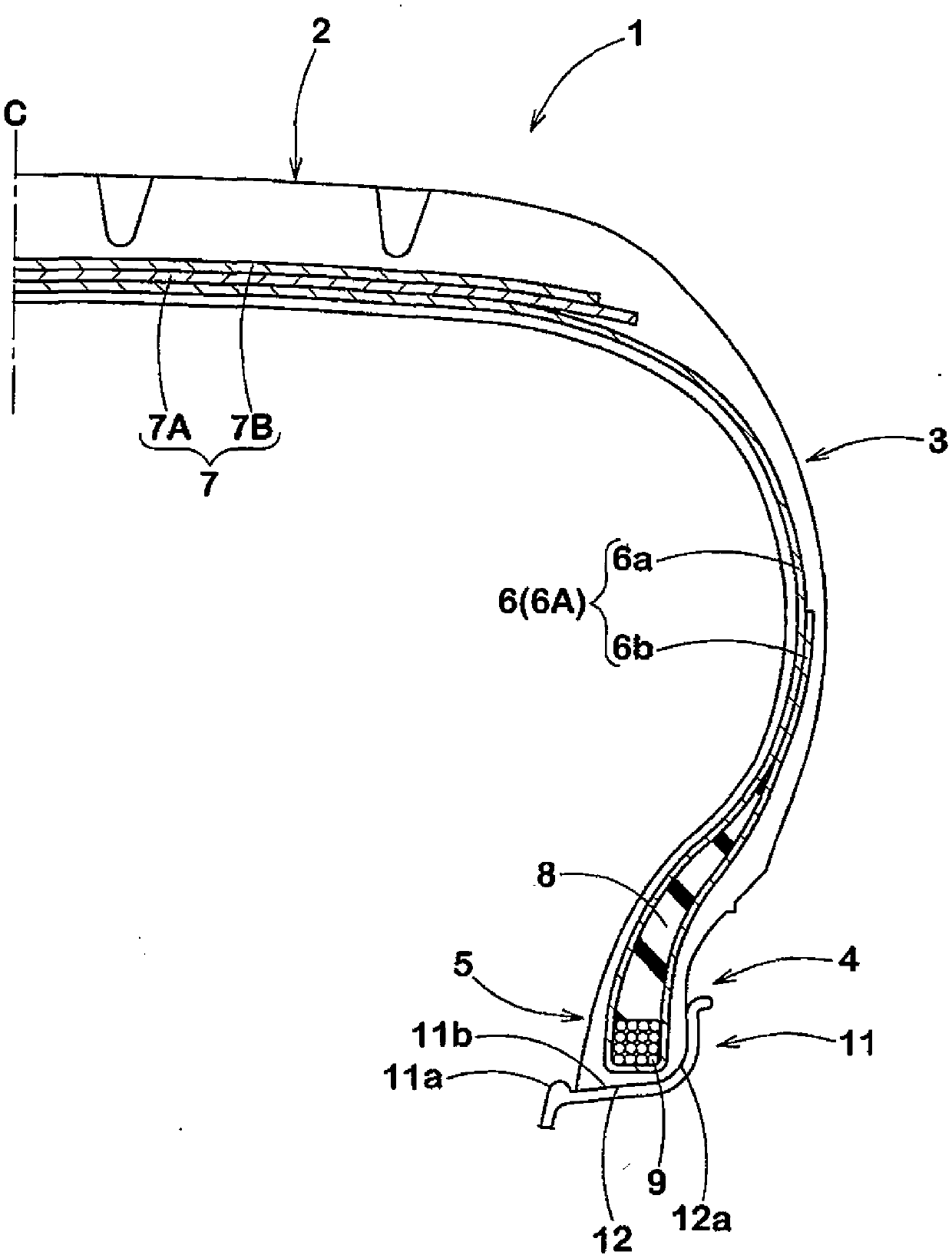

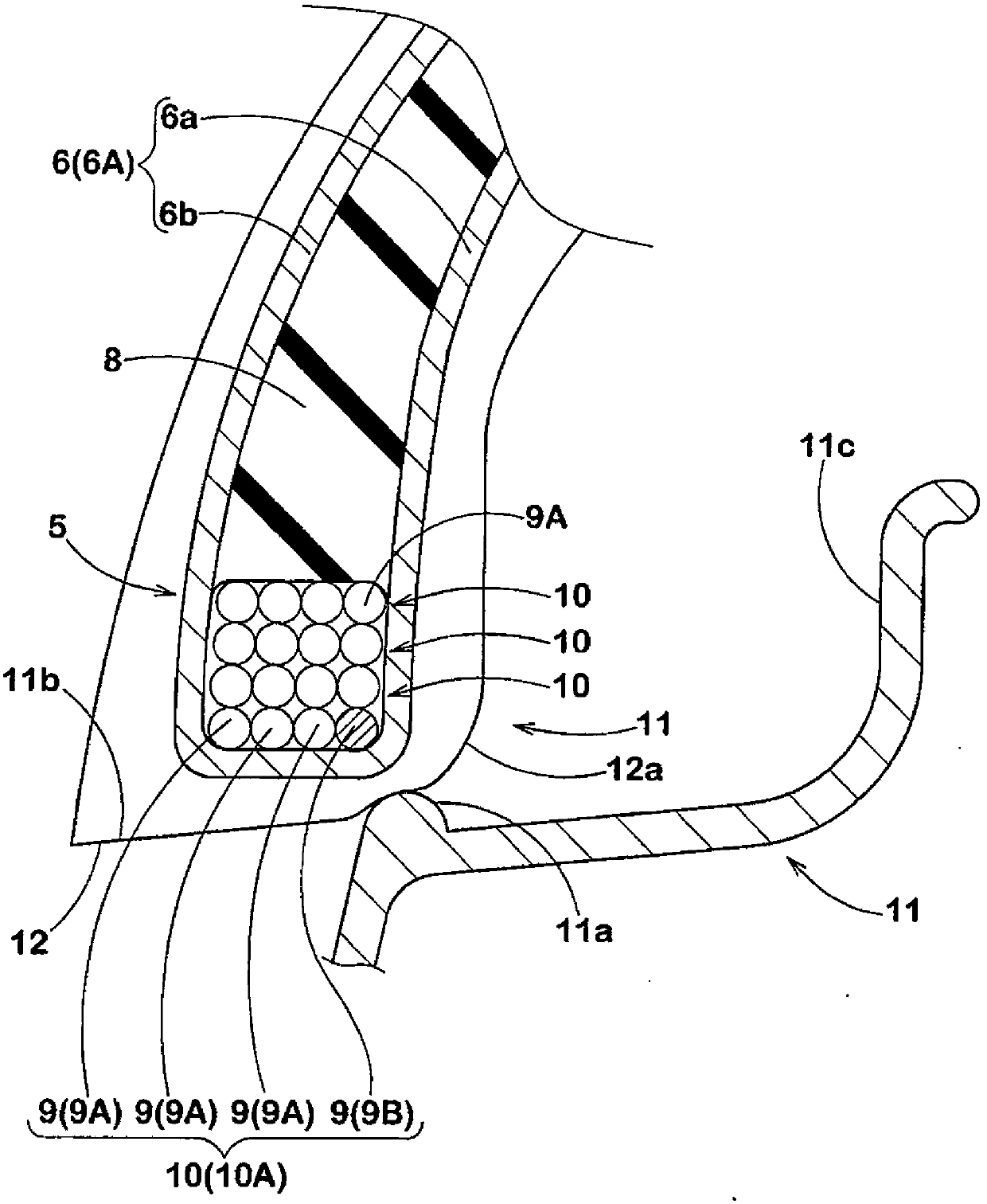

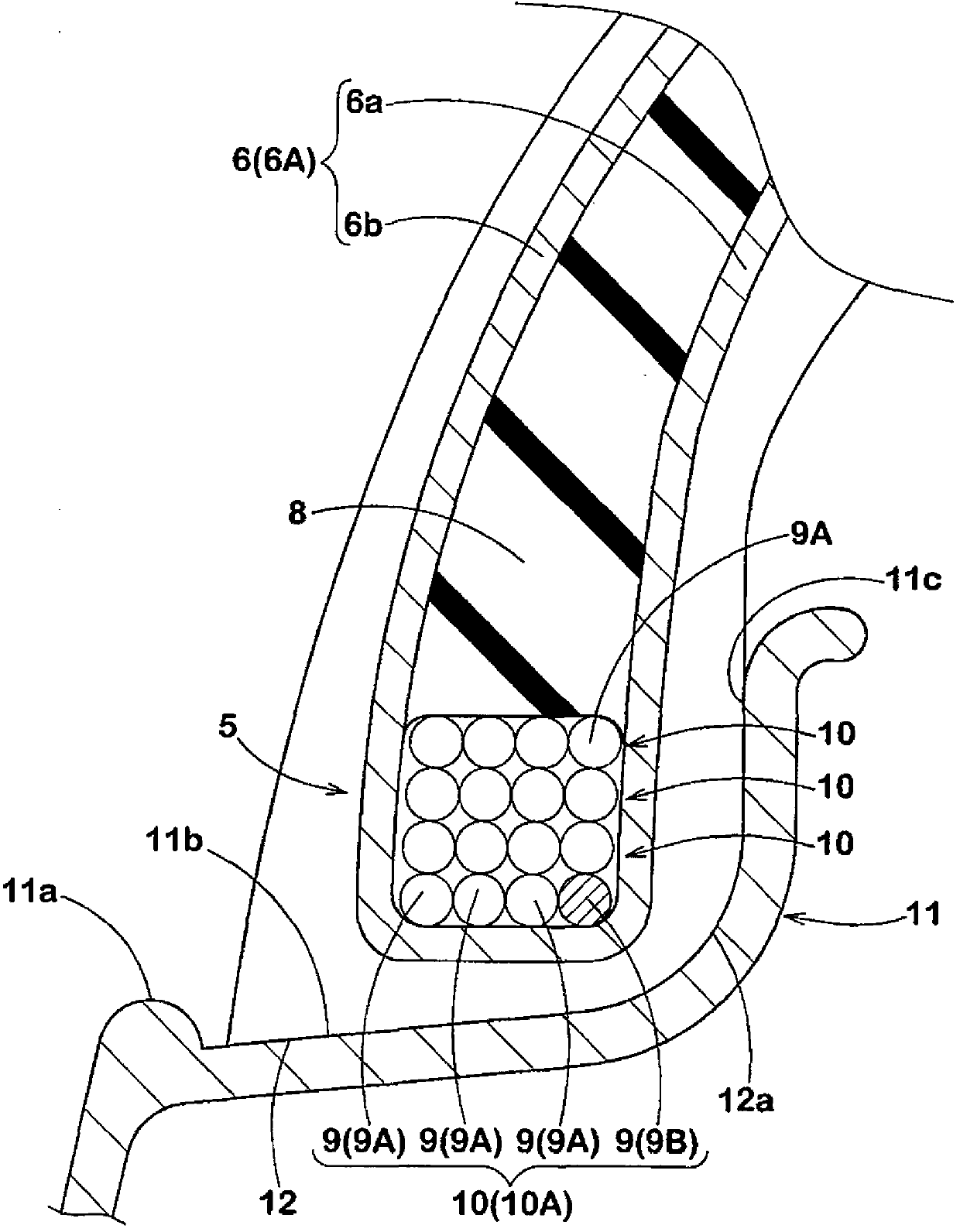

[0067] Formation of specification trial production based on Table 1 figure 1 The size of the basic structure of the pneumatic tire was 175 / 60R15, and the amount of rim misalignment and fitting pressure were tested for each test tire. In addition, the same test was performed using a conventional tire not provided with the above-mentioned second bead wire as a comparative example. The test method is as follows.

[0068]

[0069] Each test tire was installed on a regular rim of 15×6JJ, and after being filled with an internal pressure of 250kPa and left indoors for 72 hours, it was installed on a vehicle, and after a sudden stop at a speed of 50km / h, the tire and rim were measured the amount of misalignment between. The results are represented by an index of 100 for the comparative example, and the smaller the numerical value, the smaller the amount of rim misalignment.

[0070]

[0071] The fitting pressure when each test tire was mounted on the above-mentioned normal rim ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com