Mold for rectifying deformation of permanent magnetic ferrite product

A technology of permanent magnet ferrite and mould, which is applied in the manufacture of tools and ceramic molding machines, etc. It can solve the problems of reducing production efficiency, affecting the production process, increasing production costs, etc., so as to reduce production costs, improve product yield and production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

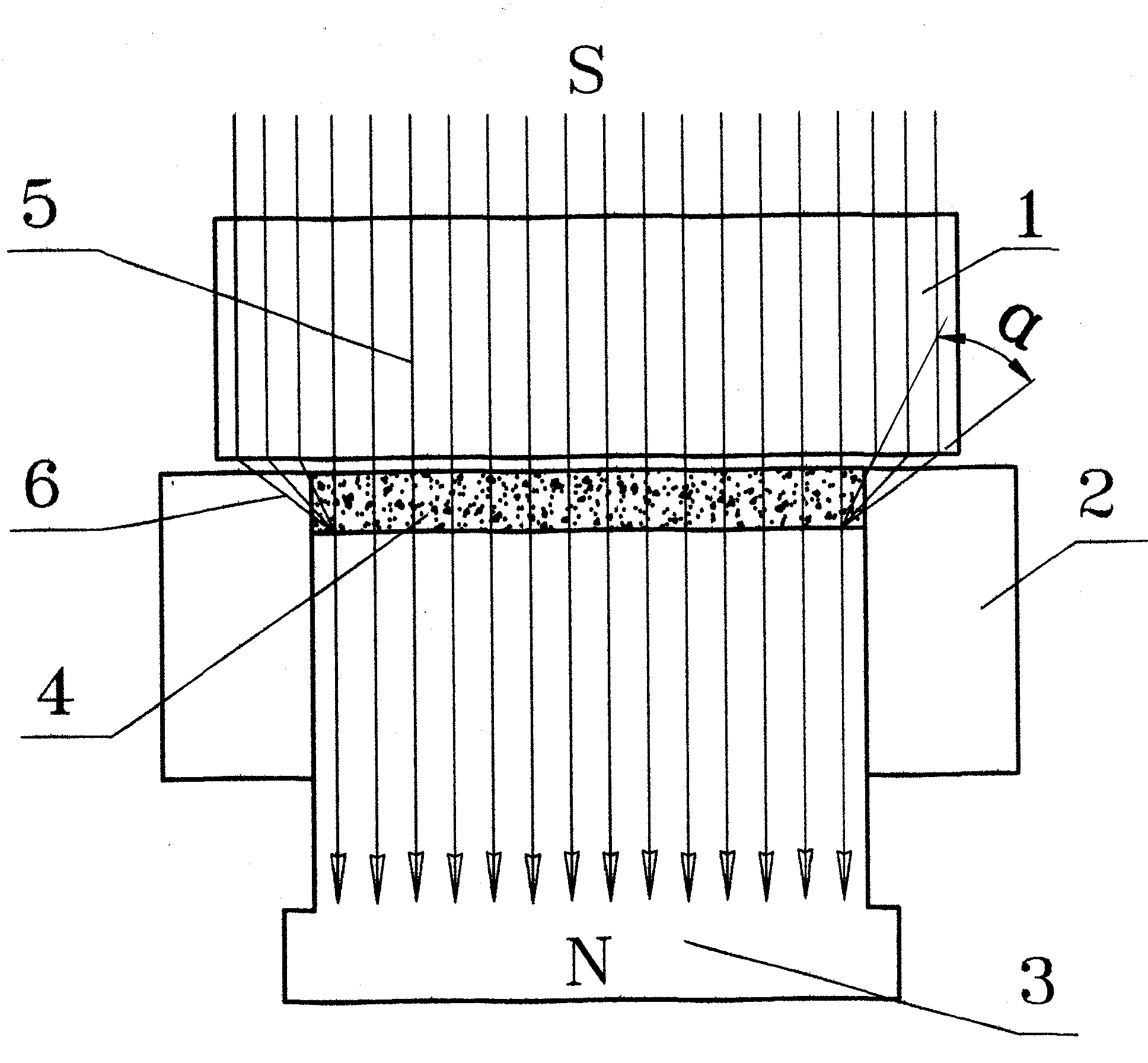

[0012] The present invention is a mold for correcting the deformation of permanent magnet ferrite products, changing the orientation magnetic field in the process of pressing and forming the product, and realizing it by changing the material of the mold. The following will be described in detail with reference to the accompanying drawings. See figure 1 , the mold for correcting the deformation of permanent ferrite products in the present invention is composed of: mold upper punch 1, die 2 and mold lower punch 3, the upper punch 1 of the mold is made of magnetically conductive material, and is made of magnetically conductive material The die lower punch 3 is contained in the die die 2 made of non-magnetic material. Since the upper punch of the mold is made of magnetically conductive material, two magnetic fields will be generated when the product is pressed: one is that the magnetic field inside the die cavity is a parallel and uniform orientation field 5; the other is that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com