A half-shell processing method with multiple spiral grooves distributed on the outer circle

A technology of helical grooves and circular distribution, applied in the field of machining, can solve the problems of thin-walled long half-shells, such as outstretching, twisting, hidden dangers, etc., and achieve the effect of improving machining accuracy and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

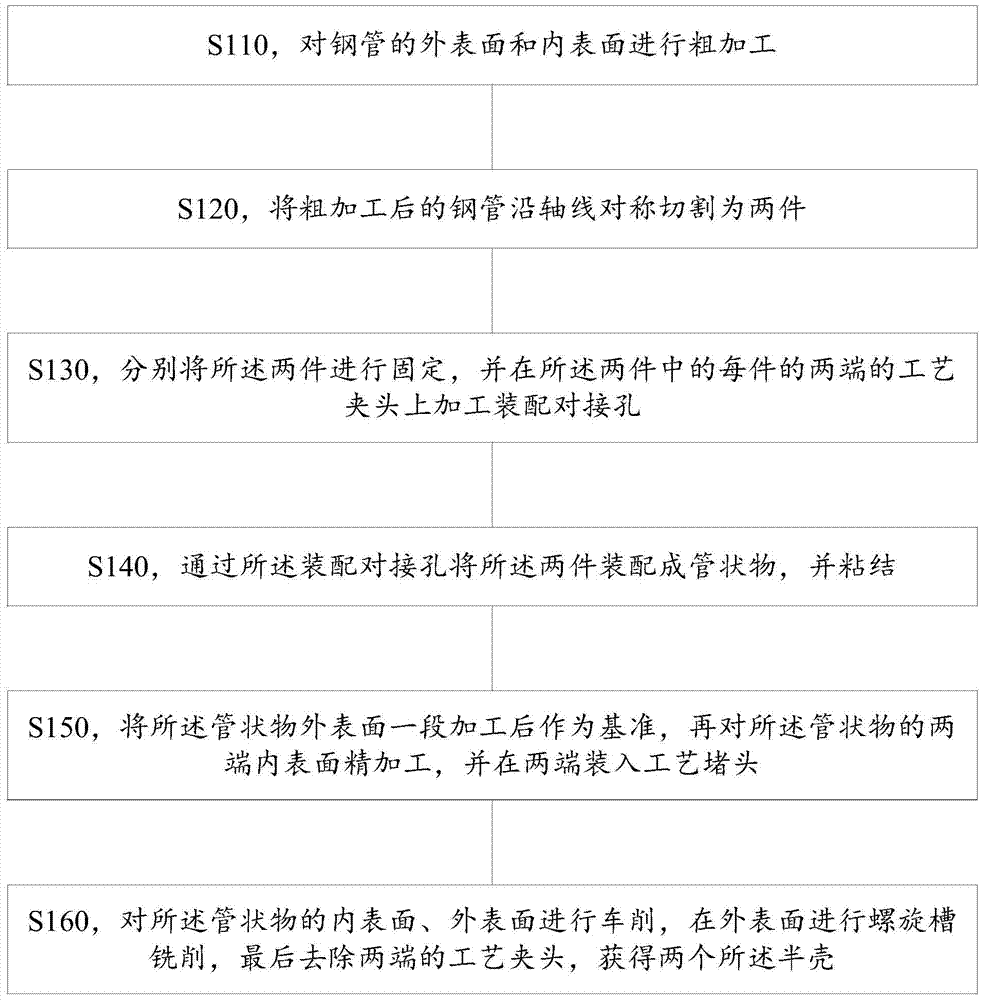

[0021] The embodiment of the present application provides a half-shell processing method with a plurality of spiral grooves distributed on the outer circle, which solves the phenomenon of stretching and twisting of the thin-walled long half-shell in the prior art after cutting, resulting in a certain tension or compression after assembly. power, there are technical problems with greater hidden dangers.

[0022] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

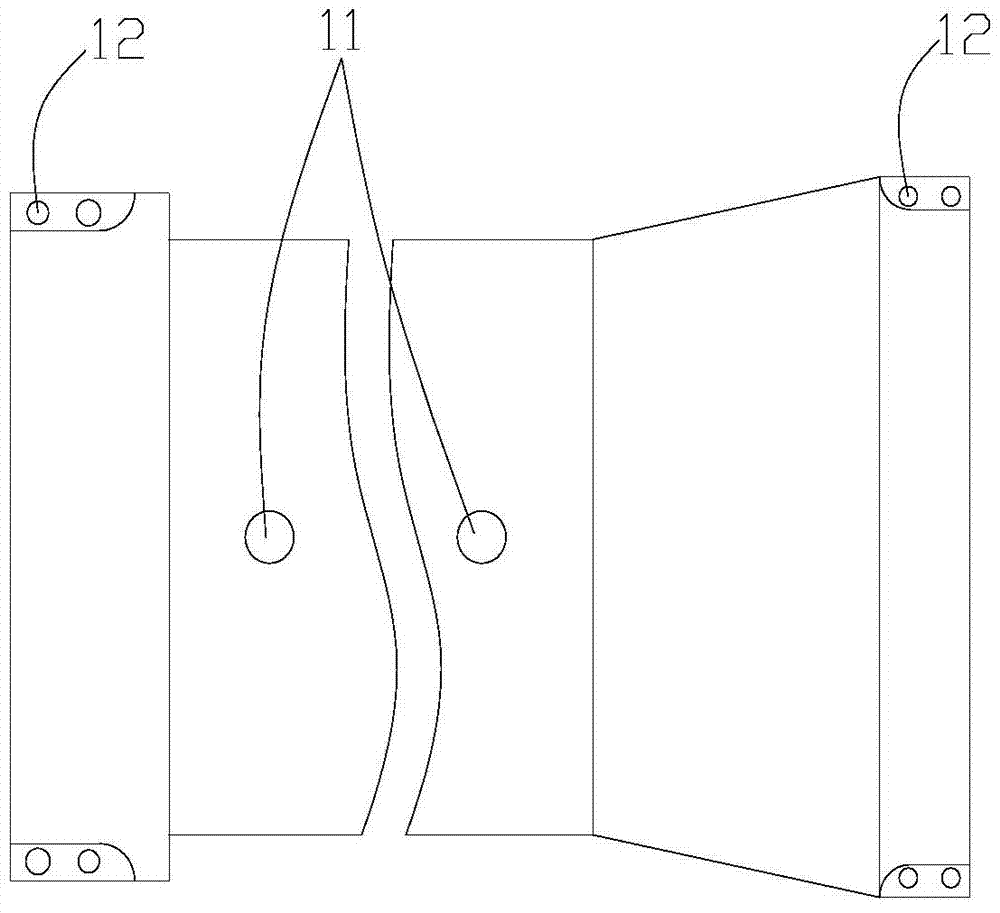

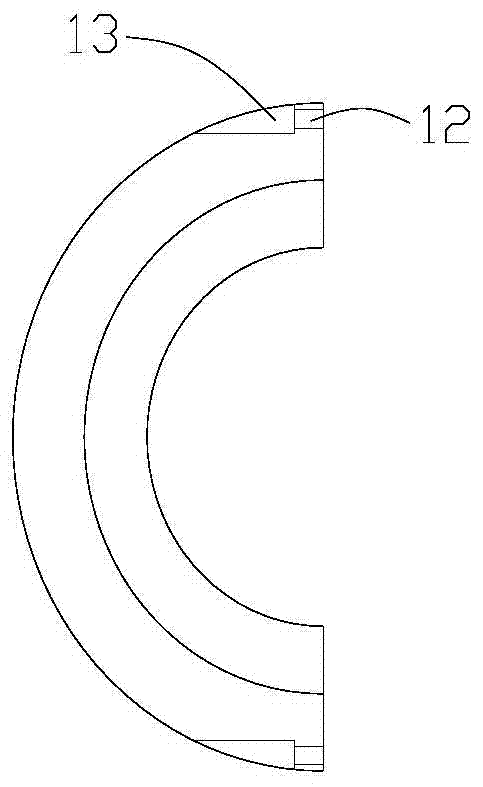

[0023] A half-shell processing method in which a plurality of spiral grooves are distributed on the outer circle, the method includes: rough machining the outer surface and the inner surface of a steel pipe; cutting the roughly machined steel pipe symmetrically into two pieces along the axis; The two pieces are fixed, and an assembly butt joint hole is processed on the process chuck at both ends of each of the two ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com