Polymer composite material, preparation method thereof and chemically modified electrode

A technology of composite materials and polymers, applied in the field of polymers, can solve the problems that graphene is easy to agglomerate and curl, and it is difficult to obtain high catalytic performance graphene-nano-copper composite materials, so as to achieve high electronic conductivity and good clinical application prospects , improve the catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

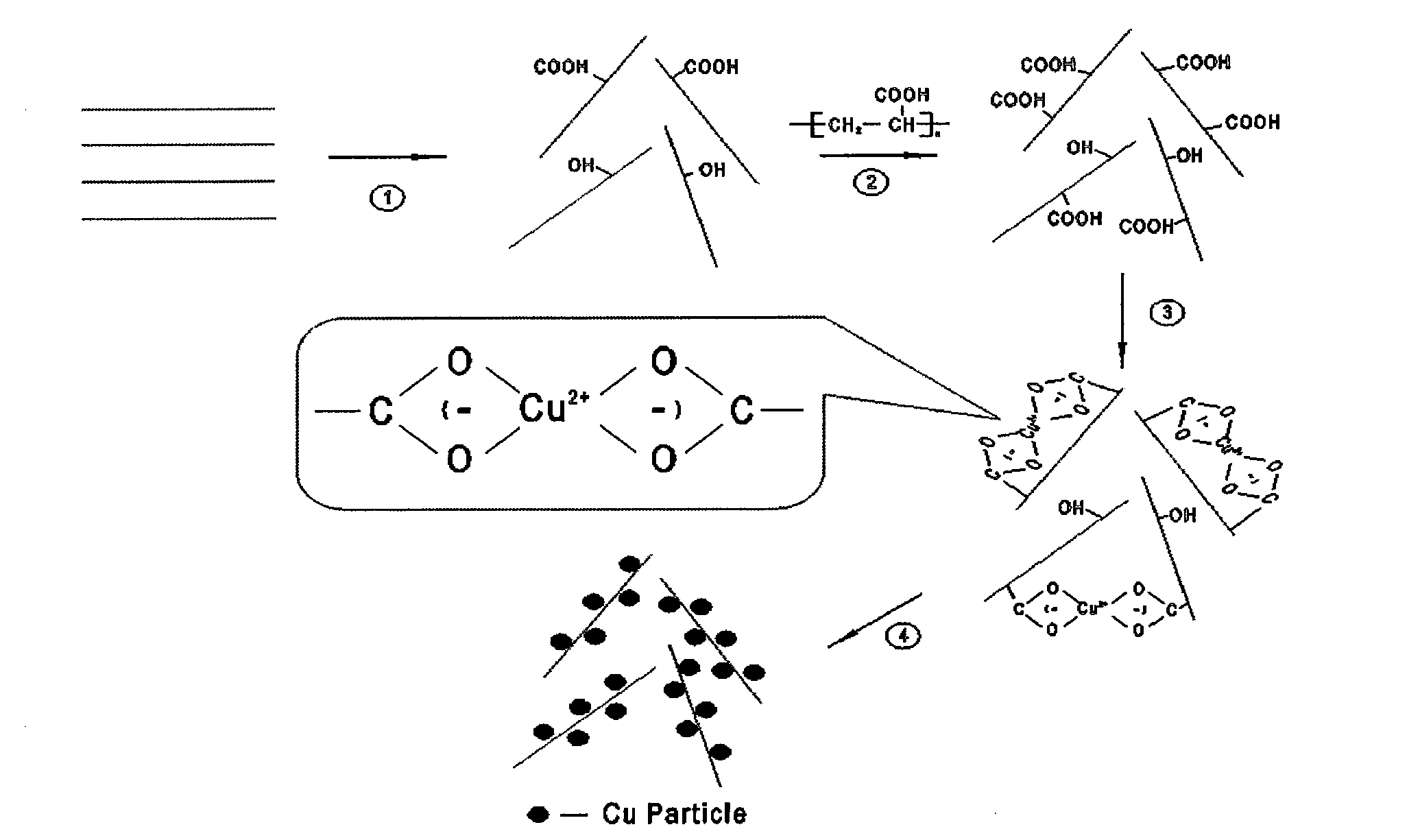

[0040] The invention provides a kind of preparation method of polymer composite material, comprises the following steps:

[0041] a) mixing graphene oxide, polyacrylic acid and metal salt compounds in a solvent to obtain a mixed solution;

[0042] b) reacting the mixed solution obtained in step a) with a reducing agent to obtain a polymer composite material. In the invention, graphene oxide, polyacrylic acid and metal salt compounds are mixed in a solvent to obtain a mixed solution. In the present invention, the graphene oxide dispersion is preferably firstly provided, and then the graphene oxide dispersion is mixed with the polyacrylic acid solution, and the graphene oxide-polyacrylic acid solution is obtained by standing still after ultrasonication. The present invention has no special limitation on the source of the graphene oxide, and the graphene oxide well known to those skilled in the art can be used. Graphene oxide was prepared. In the present invention, the graphen...

Embodiment 1

[0082] Add 2.5g of expanded graphite and 5g of sodium nitrate in a 500mL beaker, then add 120mL of concentrated sulfuric acid with a mass concentration of 98%, and stir the resulting mixture for 120min in an ice bath;

[0083] Then under the condition of strong stirring, slowly add 15g potassium permanganate to the obtained mixture for reaction, the temperature of the reaction is controlled below 20°C;

[0084] After the addition of potassium permanganate was complete, the ice bath was removed, and the resulting reaction product was stirred overnight at room temperature. As the reaction progressed, the inventor observed that the mixture in the beaker gradually turned into a paste, and the color turned into bright brown;

[0085] Finally, under vigorous stirring, 150 mL of secondary water was added dropwise to the beaker, the reaction temperature rose rapidly to 98°C, and foam was observed, and the color of the reaction product in the beaker turned yellow;

[0086] The reactio...

Embodiment 2

[0089] The graphite oxide that 30mg embodiment 1 is obtained is dispersed in 30mL secondary water, obtains graphene oxide dispersion liquid, then adds 20mL mass fraction in described graphene oxide dispersion liquid and is 15% polyacrylic acid solution, the graphene oxide that obtains - The polyacrylic acid mixed solution was ultrasonically dispersed for 4 hours, and left to stand overnight;

[0090] Then, under strong stirring conditions, 50 mL of copper chloride with a molar concentration of 0.2 mol / L was added to the overnight graphene oxide-polyacrylic acid mixed solution, and continued strong stirring for 2 h at room temperature to obtain a mixed solution;

[0091] Finally, NaBH with a molar concentration of 0.4 mol / L was mixed under stirring conditions 4 The solution was added dropwise to the above mixed solution until the color of the solution completely changed from blue to brown, then the addition was stopped to obtain the reaction product;

[0092] The obtained reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com