Method for preparing low-fat yogurt

A technology of fatty acid and yogurt, which is applied in the field of preparation of low-fat yogurt, and can solve problems such as increasing product cost and technical difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

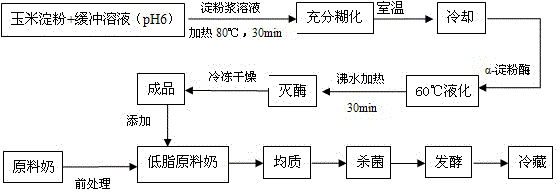

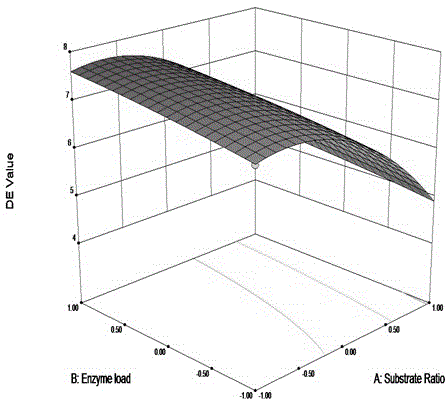

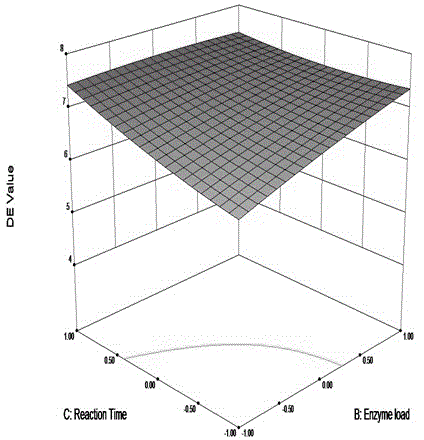

[0016] A method for preparing low-fat yogurt, the method comprising the following steps: (1) adding a buffer solution of pH=6 to cornstarch to prepare a cornstarch solution, heating the cornstarch solution at a constant temperature of 80°C for 30 minutes, and simultaneously Stirring treatment, let it fully gelatinize, and cool to 50°C after gelatinization; (2) Add α-amylase to the gelatinized cornstarch solution obtained in step (1) for enzymolysis, and inactivate the enzyme after enzymolysis, The enzymolysis product is obtained, and the enzymolysis parameters are as follows: the enzyme addition amount is 6-8U / g, the corn starch substrate concentration is 10-14%, the enzymolysis time is 10-20min, and the DE value of the enzymolysis product is controlled as 3.2-3.6; (3) After cooling the enzymatic hydrolysis product to room temperature, freeze-dry it to obtain a dry powder, and grind the dry powder with a tissue mixer to obtain a fat substitute; (4) Centrifuge the raw milk for d...

Embodiment 1

[0020] (1) Preparation of cornstarch fat simulant: under the conditions of enzyme dosage 7U / g, substrate concentration 12%, enzymolysis time 20 min, DE value of hydrolyzate was 6.80, the hydrolyzate was freeze-dried, After becoming a dry powder, the yellow-white powder formed by crushing with a tissue mixer is the finished fat substitute;

[0021] (2) Inspection and standardization of raw milk: 72° alcohol and protein are stable, acidity ≤ 18°T, and there is no antibiotic residue in the inspection; use a centrifuge to skim the whole milk, the skimming temperature is 55°C, and the skimming pressure is 0.5bar;

[0022] (3) Add fat simulant: Add the corresponding fat substitute powder according to the fat substitution degree of 50%;

[0023] (4) Sterilize the raw milk after homogenization; the material is homogenized at 18-20MPa / 65°C, and sterilized at 100°C / 300S;

[0024] (5) Cooling inoculation, fermentation, and refrigeration: cool the material to 45°C, add direct-injection s...

Embodiment 2

[0026] (1) Preparation of cornstarch fat simulant: under the conditions of enzyme dosage 5U / g, substrate concentration 10%, enzymolysis time 15min, DE value of hydrolyzate was 6.92, and the hydrolyzate was freeze-dried to become After the powder is dried, the yellow-white powder formed by crushing with a tissue mixer is the finished fat substitute;

[0027] (2) Inspection and standardization of raw milk: 72° alcohol and protein are stable, acidity ≤ 18°T, and there is no antibiotic residue in the inspection; use a centrifuge to skim the whole milk, the skimming temperature is 55°C, and the skimming pressure is 0.5bar;

[0028] (3) Add fat simulant: Add the corresponding fat substitute powder according to the fat substitution degree of 70%;

[0029] (4) Sterilize the raw milk after homogenization; the material is homogenized at 18-20MPa / 65°C, and sterilized at 100°C / 300S;

[0030] (5) Cooling inoculation, fermentation, and refrigeration: cool the material to 45°C, add direct-i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com