High-rotation-speed transmission gear experiment table

A test-bed, high-speed technology, applied in the field of test-beds, can solve the problems of important high-speed gearbox operation performance, inability to meet test requirements, transmission power affecting vehicle performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

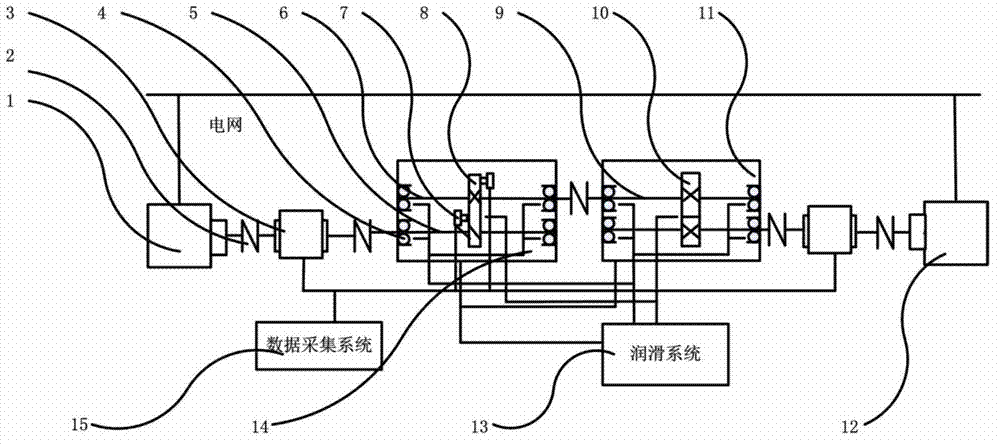

[0021] The structural principle and working principle of the present invention will be further described in detail below in conjunction with the accompanying drawings.

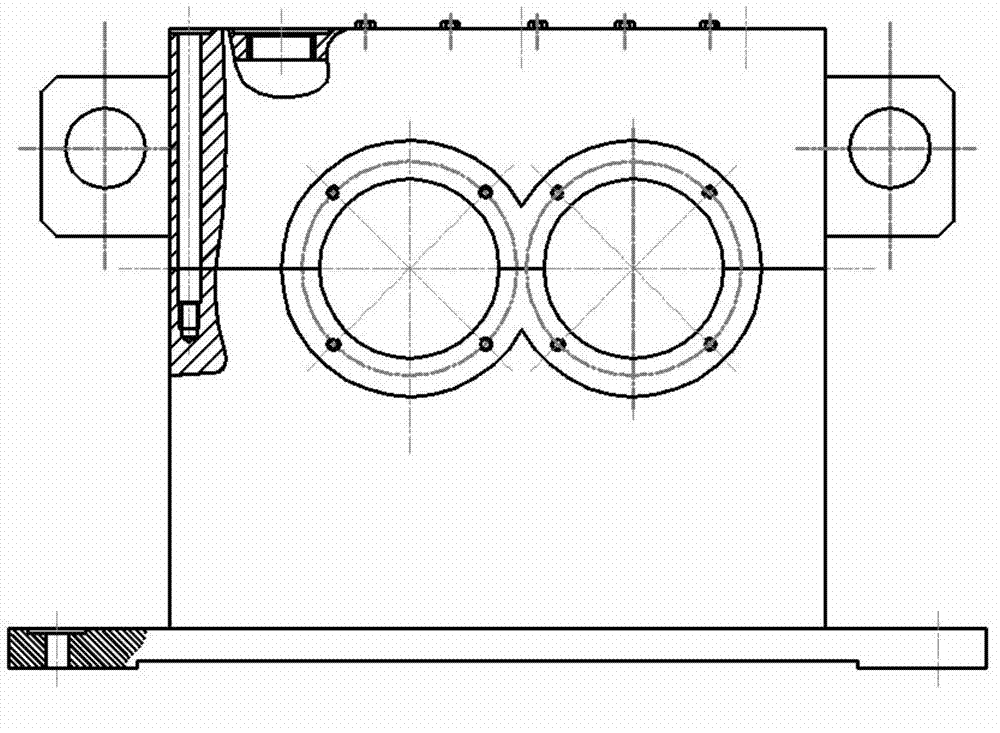

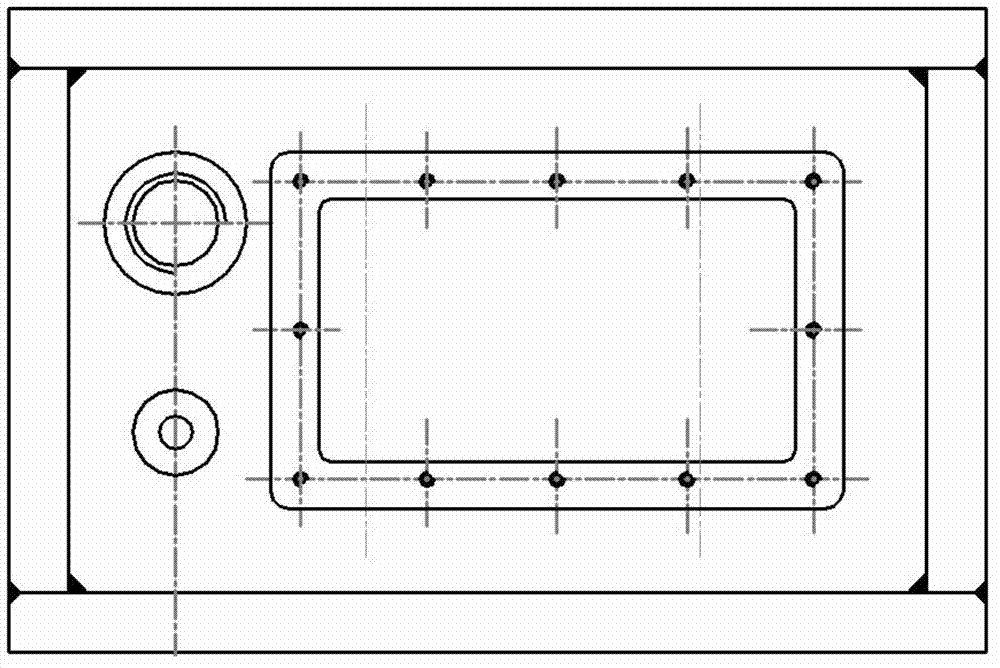

[0022] see figure 1 , the present invention includes the first three-phase asynchronous variable frequency motor 1 as an output motor, the output speed is up to 10,000rpm, the output shaft of the three-phase asynchronous variable frequency motor 1 is connected with the input shaft 5 of the gear box 14 through a high-speed coupling 2, There is a torque speed sensor 3 at the front end of the high-speed coupling, and a roller bearing 4 supporting the transmission shaft is also arranged in the box 14. The input shaft 5 is connected to the pinion on the tested gear pair 8, and the tested gear The meshing of the small gear and the large gear of pair 8 is stable. On the large gear of the tested gear pair 8, a temperature sensor 7 is installed at the tooth root and top of the gear respectively, which can collect the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com