Wood drying machine

A drying machine, wood technology, applied in the direction of drying machine, drying, local mixing dryer, etc., can solve the problems of low energy utilization rate, poor effect, limited maximum temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

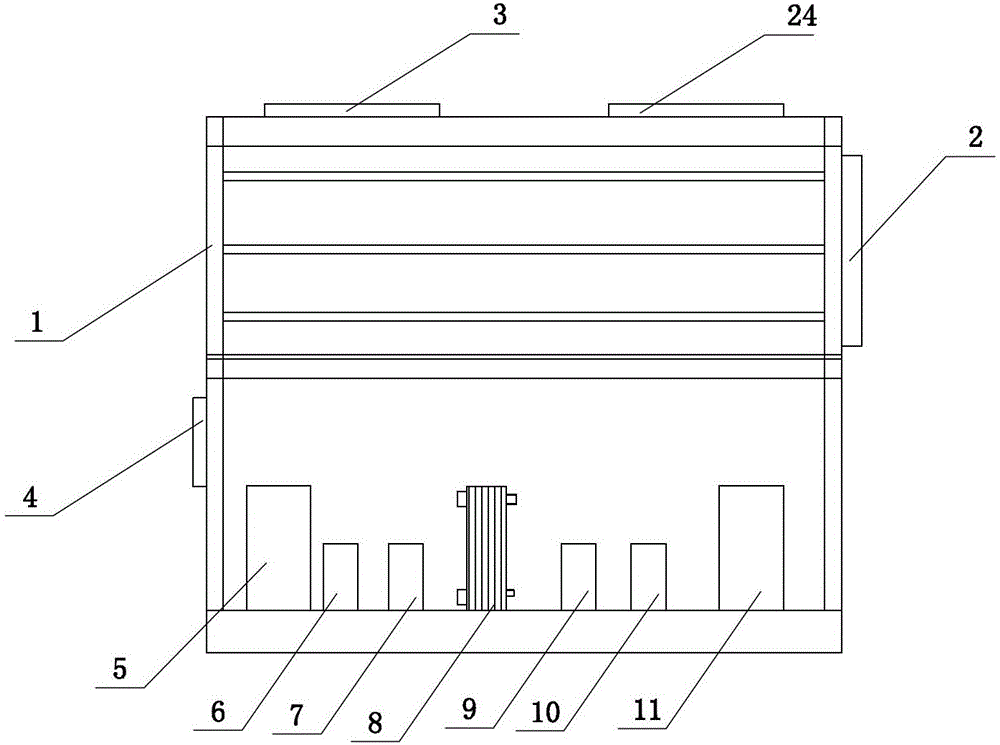

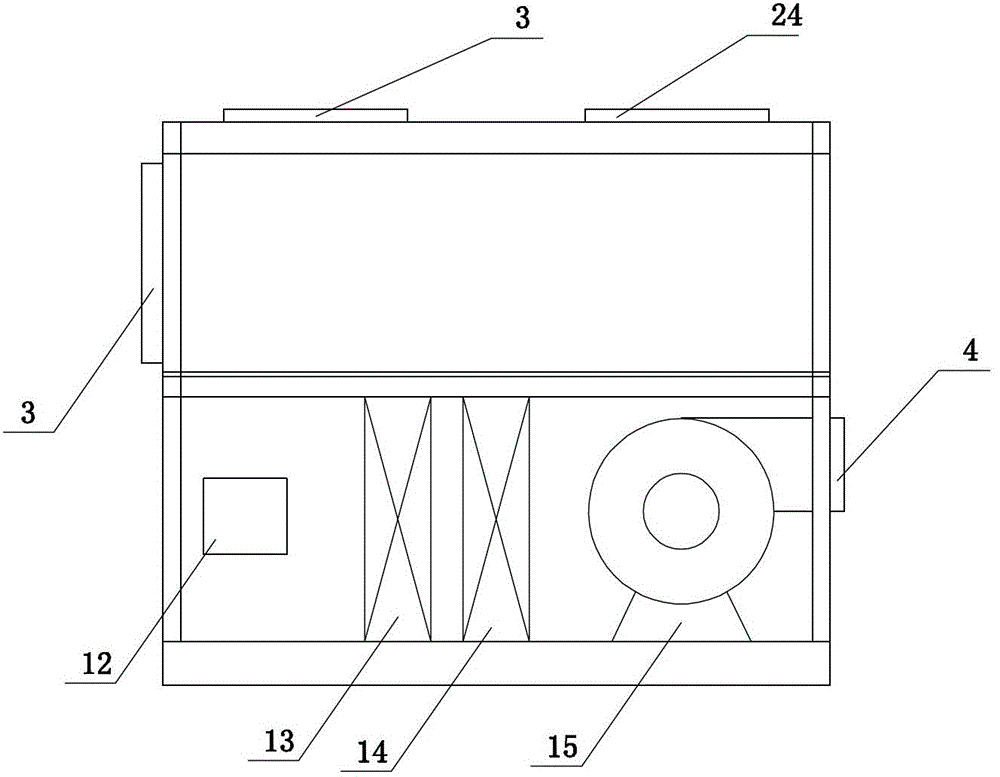

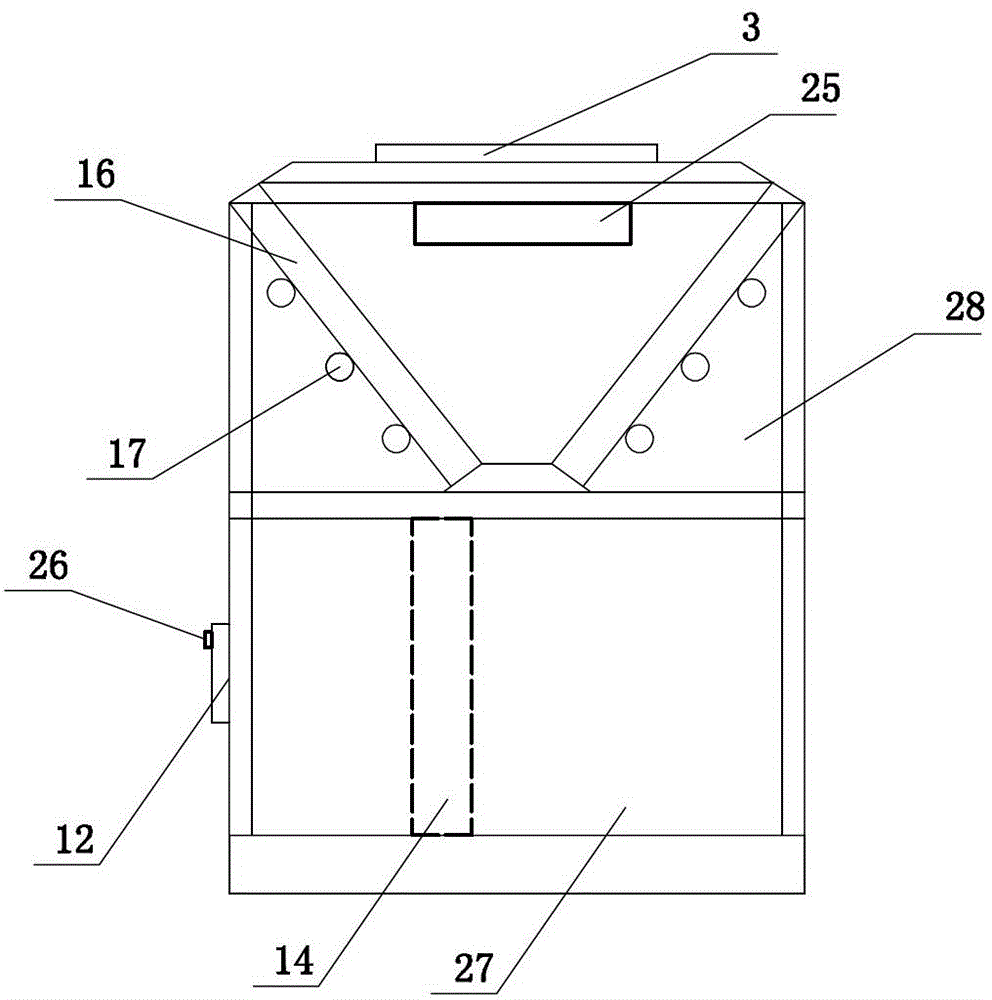

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0018] combined with figure 1 to attach Figure 4 , a wood drying machine, which includes a casing 1, a controller 2, a power supply, a low-temperature compressor 5, an intermediate heat exchanger 8, a high-temperature compressor 11, an internal evaporator 13, a condenser 14, an external evaporator 16, The first solenoid valve 18, the second solenoid valve 19, the first throttling member 20, the second throttling member 22, the temperature and humidity sensor 26, the condenser chamber 27 and the external evaporator chamber 28; the inside of the condenser chamber 27 Including the first air supply port 4, the first air return port 12 and the first air blower 15 for sending the air in the condenser chamber 27 into the drying room; the external evaporator chamber 28 includes the second air supply port 3, the second return air port The tuyere 24 and the second b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com