LED (light emitting diode) lamp and illumination system

A technology of LED lamps and lighting systems, which is applied to lighting devices, lighting and heating equipment, and components of lighting devices, and can solve problems such as small lighting angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Such as figure 1 As shown, the LED lamp provided by the embodiment of the present invention includes a bracket 11 and a plurality of LED chips fixed on the bracket 11, and the bracket 11 is formed with a first special-shaped lens 14 covering each LED chip. A second special-shaped lens 16 is molded on the lens 14, wherein the convex surface of the second special-shaped lens 16 corresponds to the concave surface of the first special-shaped lens 14, and the concave surface of the second special-shaped lens 16 corresponds to the convex surface of the first special-shaped lens 14, The LED chip is located under the convex or concave surface of the first shaped lens 14 . At this time, the convex surface of the first special-shaped lens 14 (similar to a convex lens) converges the light emitted by the LED chip to enter the second special-shaped lens 16, and the concave surface of the first special-shaped lens 14 (similar to a concave lens) emits light from the LED chip. After t...

Embodiment 2

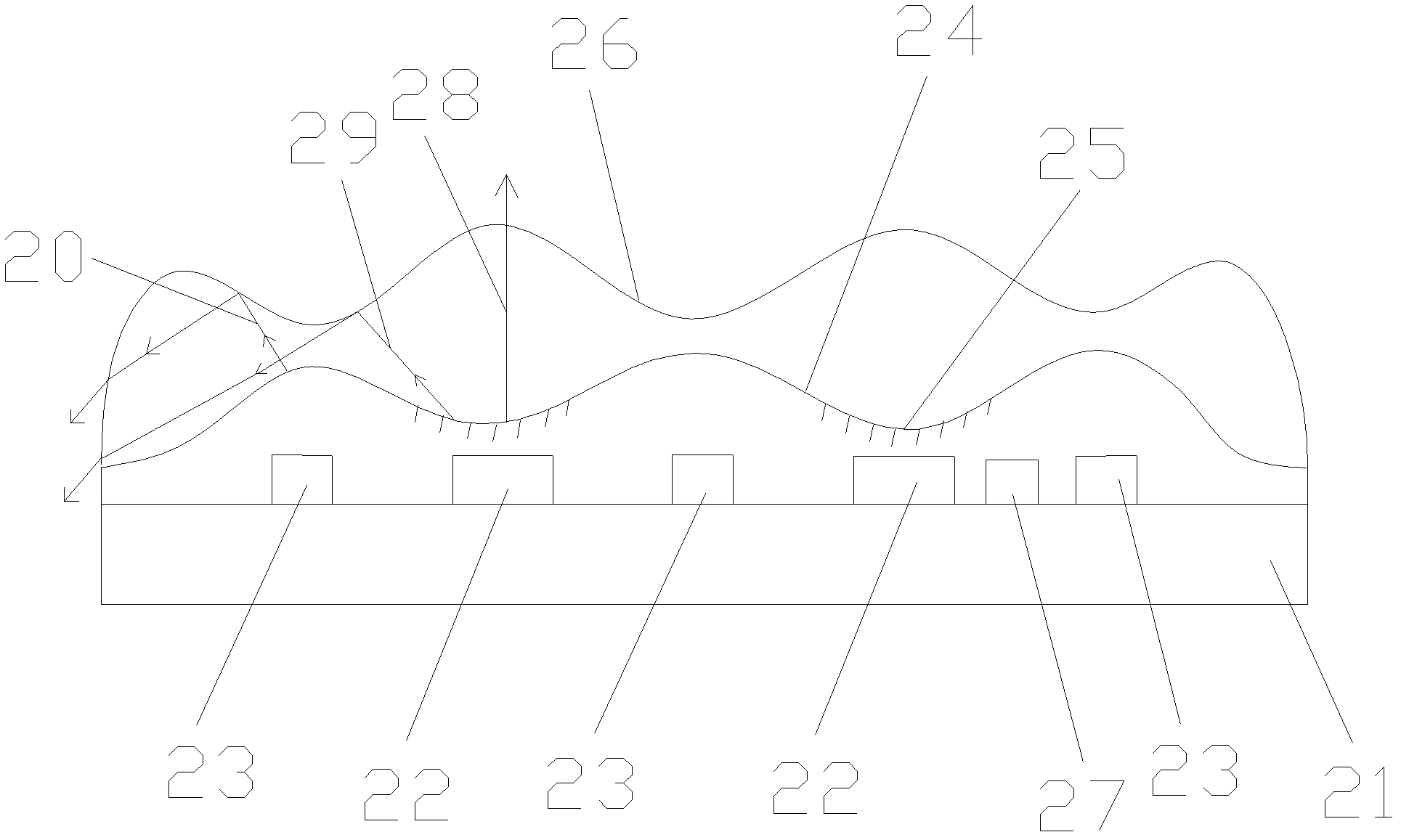

[0023] The difference from Embodiment 1 is that three red light chips 23, two blue light chips 22 and one thermistor 27 are fixedly connected to the bracket 21, and the red light chips 23 are arranged around the blue light chip 22, wherein the red light chip 23 , blue light chip 22 and thermistor 27 are connected with drive circuit by electrode line, as figure 2 shown. First, the first special-shaped lens 24 is formed on the top of the chip by one-time molding. The first special-shaped lens 24 has a plurality of concave and convex surfaces that are connected together alternately. Concave surfaces are formed, and a yellow or yellow-green phosphor layer 25 is uniformly coated on each concave surface to generate white light. Then, the second special-shaped lens 26 is formed by one-shot molding above the first special-shaped lens 24. The second special-shaped lens 26 also has a plurality of concave and convex surfaces that are connected together alternately. The convex surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Excitation wavelength | aaaaa | aaaaa |

| Excitation wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com