Method for producing fumaric acid by maleic anhydride waste water

A technology for fumaric acid and waste water, which is applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve problems such as the rare disclosure of improved technology, achieve simple and controllable process, and solve production problems The problem of the back road and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

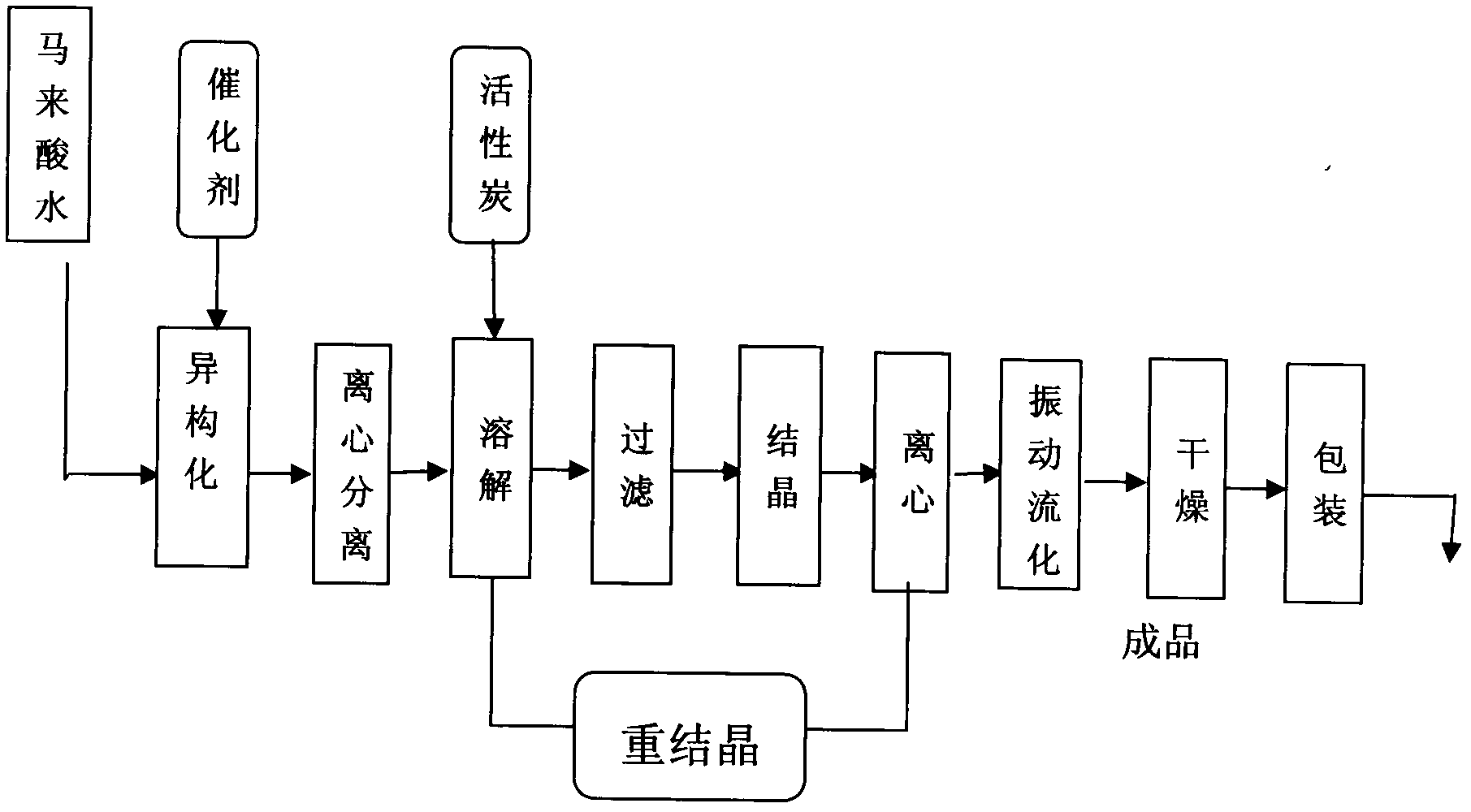

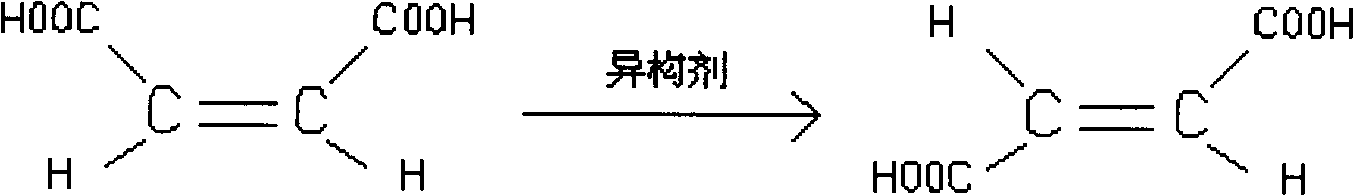

[0012] The process of the invention comprises a maleic acid isomerization reaction process, a fumaric acid primary product centrifugal separation process, a fumaric acid dissolution and decolorization process, a filtration process, a fumaric acid recrystallization process, a centrifugation process and a fumaric acid drying and packaging process. Specifically, maleic anhydride wastewater is added with a catalyst for isomerization reaction, after centrifugation, activated carbon is added for dissolution and decolorization, filtration and crystallization, recrystallization, and then centrifuged and dried. The fumaric acid in the waste acid water in the maleic anhydride production process can be fully recovered and refined into industrial-grade fumaric acid products.

[0013] Among them, the maleic acid isomerization reaction process includes: pumping the cooled maleic acid aqueous solution to the isomerization reaction kettle, the isomerization kettle is a 12 cubic reaction kettle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com