Microfluid-based self-breathing photocatalytic film-free fuel battery

A fuel cell and self-breathing technology, which is applied in the direction of fuel cells, circuits, electrical components, etc., to achieve the effect of convenient manufacturing, low cost, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

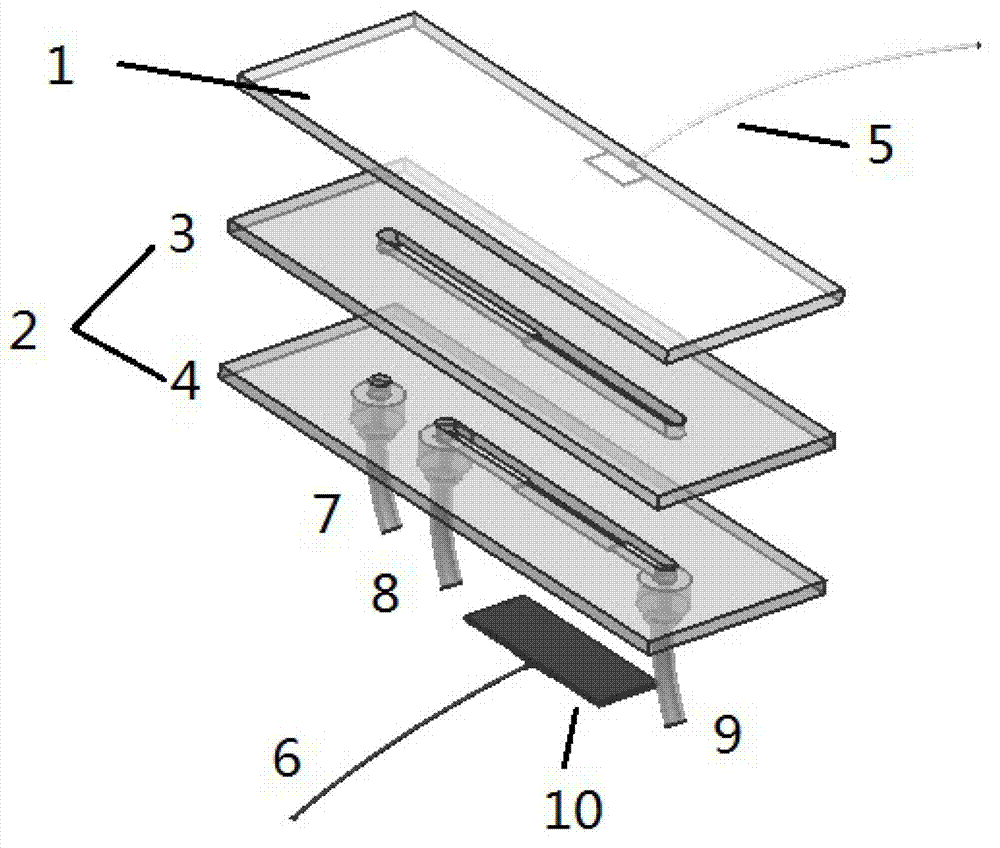

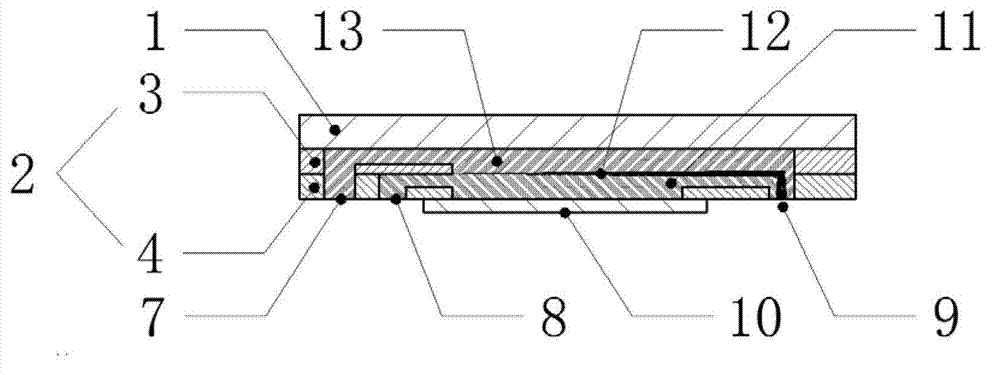

[0035] exist figure 1 Among them, the photocatalyst-loaded conductive glass 1 and the battery chip 2 constitute the main body of the microfluidic photocatalytic membraneless fuel cell. Two sections of grooves and two through holes are engraved on the substrate I3, the front section is a groove (length 16mm, width 2mm, depth 0.4mm), the rear section is a through groove (length 17mm, width 2mm, depth 0.5mm), the groove and The photocatalyst-loaded glass is bonded to form the anode inlet channel, the through groove and the through groove of the substrate II4, the conductive glass and the gas diffusion electrode 10 are bonded to form the battery micro flow channel. There are three sections of grooves and three holes engraved on the base plate II, and the front and rear sections (the entrance end is the front, the exit end is the back) are grooves (the front section is 8mm long, 2mm wide, and 0.4mm deep; the rear section is 7mm long, 2mm wide, and deep 0.4mm), the middle section i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com