An Adsorption Method for Rapid Assembly of Virtual 3D Components

A virtual three-dimensional, component technology, applied in special data processing applications, image data processing, instruments, etc., can solve the problems of cumbersome operation, difficult to accurately locate, not intuitive, etc., to achieve clear algorithms, improve efficiency, and robust results Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

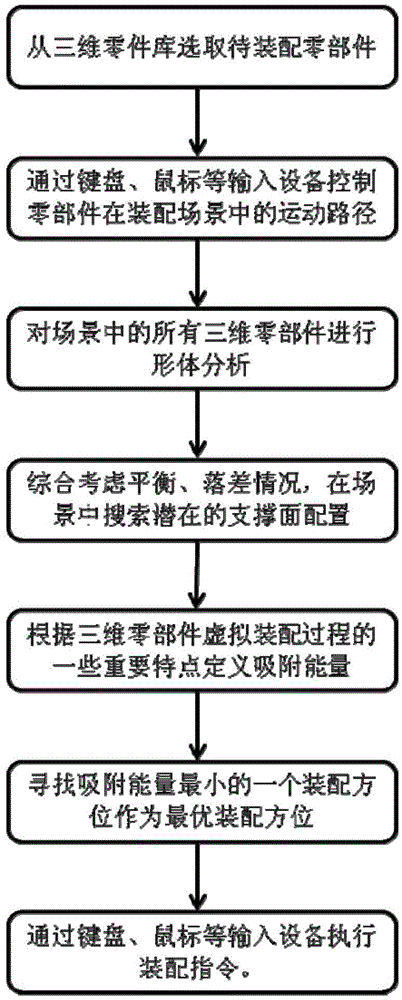

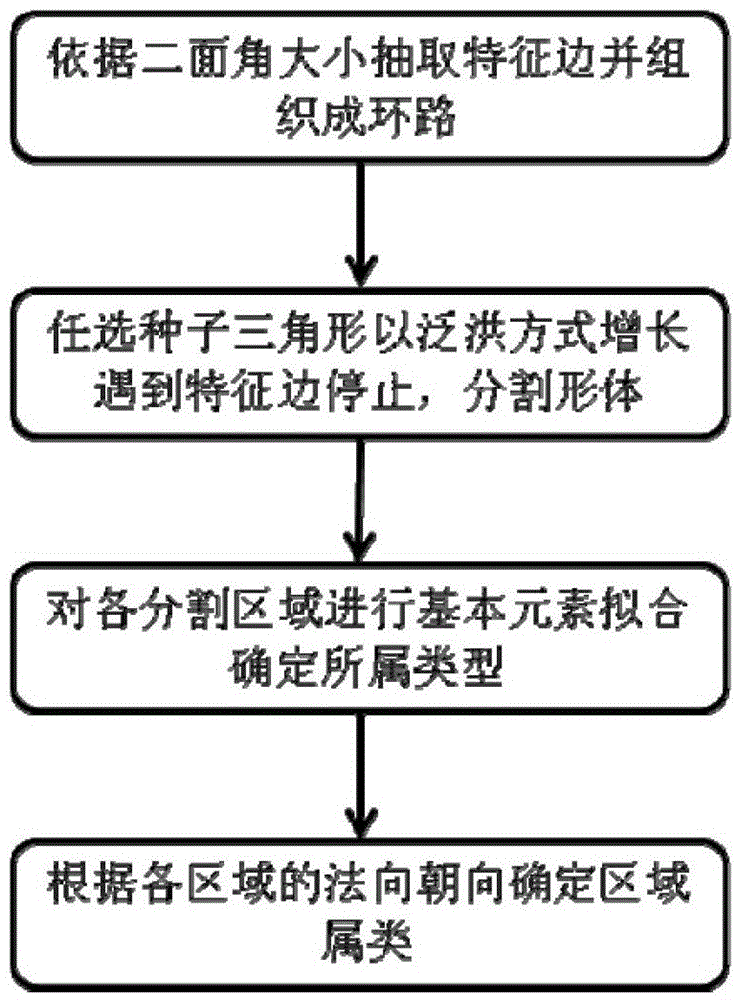

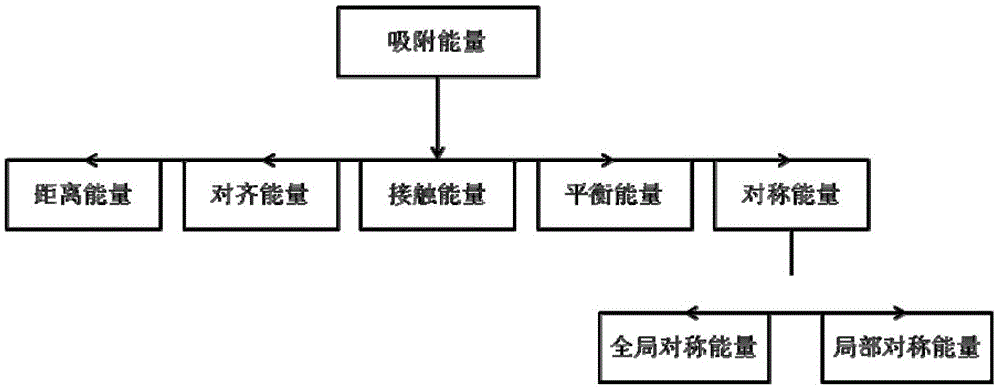

[0027] see Figure 1~4 , an adsorption method for rapid assembly of virtual 3D parts: the user first selects the parts to be assembled from the model library, and then manipulates (translates, rotates) the current parts to be assembled in the scene through input devices such as keyboard and mouse, The system first analyzes the shape of all parts in the scene, divides them into basic surfaces (cylindrical, conical, plane, etc.) and classifies them according to the orientation; The supporting surface of the assembled parts; then define and calculate the adsorption energy of the parts to be assembled according to some important characteristics and requirements of the virtual assembly process of the three-dimensional parts, such as symmetry and alignment, and finally determine the optimal Assembly orientation. See the specific process figure 1 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com